Deformation adapter and die for manufacturing deformation adapter

A technology of adapter and mandrel, which is applied in the field of solid rocket motor devices, can solve the problems of shell deformation, expansion deformation, etc., and achieve the effects of preventing pressure deformation, reducing deformation, and facilitating processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

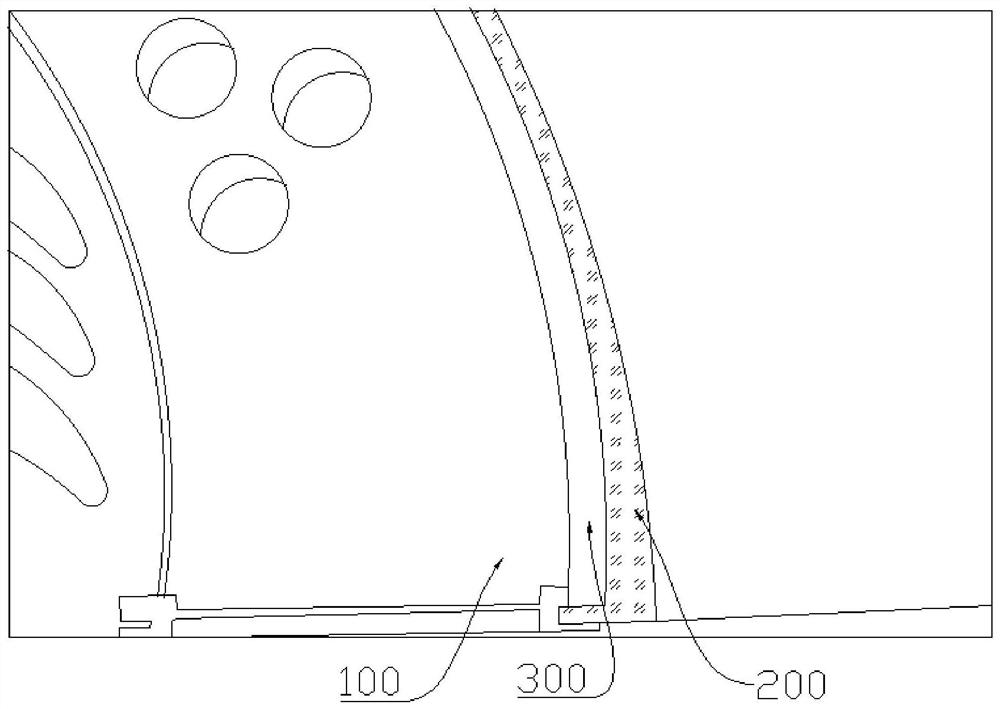

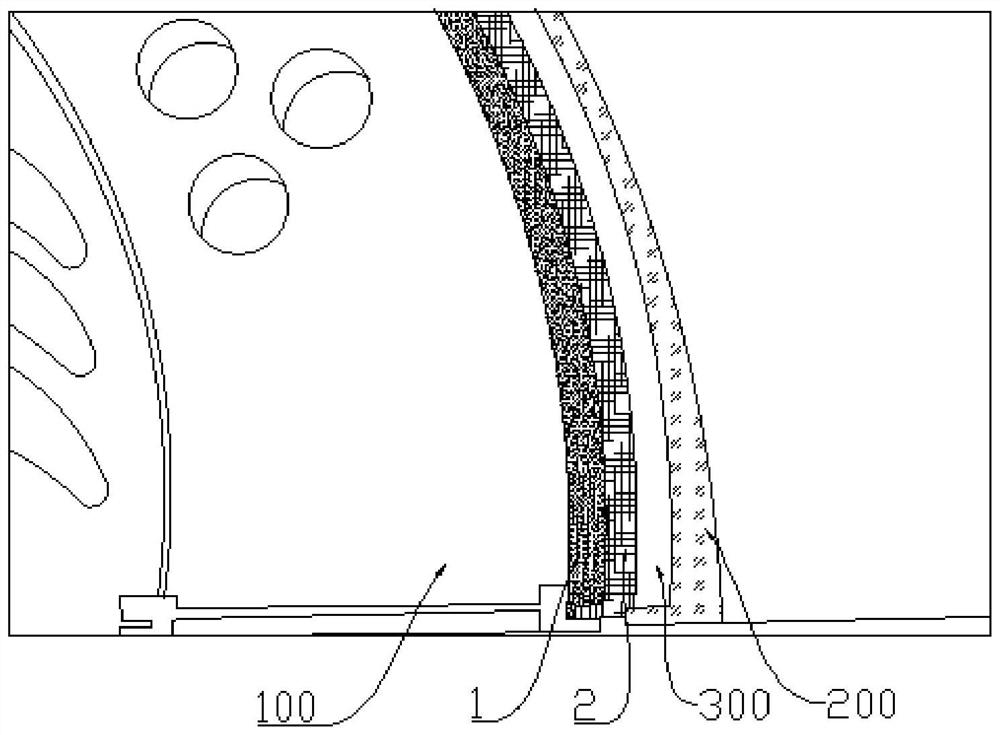

[0041] like Figure 2-Figure 4 As shown, this embodiment provides a deformed adapter, including an adapter body 1, the inner contour of the adapter body 1 is matched with the outer contour of the core mold skeleton 100, the adapter body 1 is sleeved on the core mold skeleton 100, and is located in the core mold skeleton 100. Between the core mold skeleton 100 and the outer shell 200 , the adapter body 1 is made of elastic material, and can deform and shrink when the core mold skeleton 100 expands at high temperature, so as to prevent the outer shell 200 from being deformed.

[0042] In the deformed adapter of this embodiment, an adapter body 1 is arranged between the core mold skeleton 100 and the outer shell 200 , and the adapter body 1 is attached to the core mold skeleton 100 . The contour is adapted, and the deformation adapter is made of elastic material. When the outer shell 200 and the core mold skeleton 100 are cured at high temperature, the core mold skeleton 100 is t...

Embodiment 2

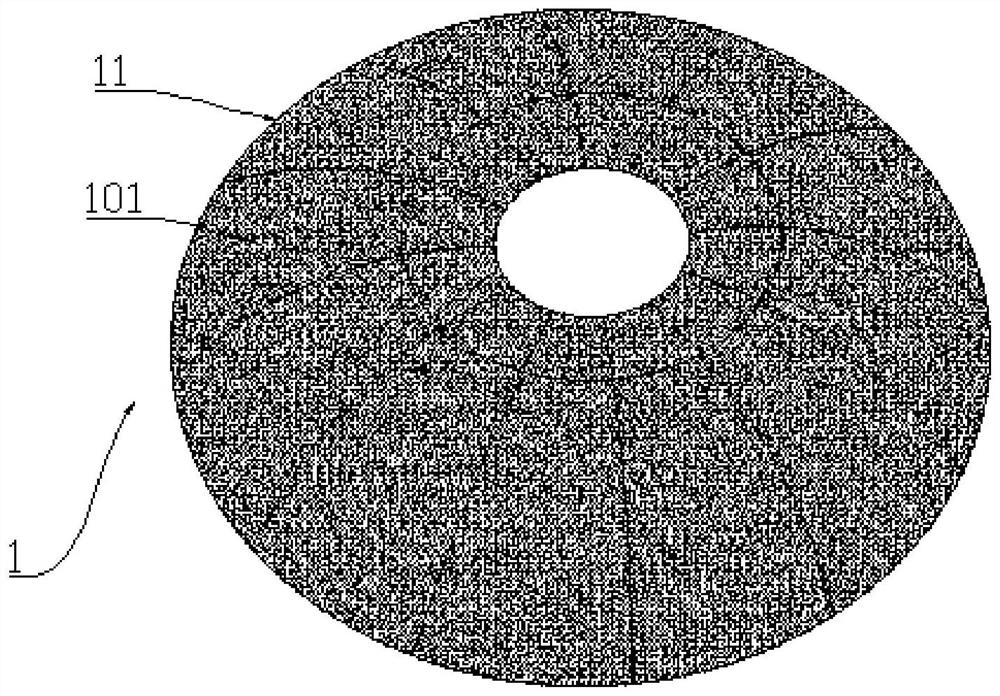

[0055] see Figure 5-Figure 12 As shown, this embodiment provides a mold for manufacturing the above-mentioned deformed adapter. The mold includes a base 5, a movable mold 4 and a fixed mold 3 with a gate 6, wherein: the base 5 is fixed and supported on the movable mold 4 and the fixed mold 3. The bottom of the fixed die 3, among the movable die 4 and the fixed die 3, one of the inner profiles is adapted to at least part of the convex surface of the adapter body 1, and the other inner profile is compatible with at least part of the concave surface of the adapter body 1 Matchingly, the movable mold 4 and the fixed mold 3 are connected to form a cavity. see Image 6 As shown, the fixed mold 3 is provided with a pouring gate 6 for pouring the silicone rubber liquid into the cavity.

[0056] Wherein, the above-mentioned "at least part of the adapter body 1" refers to a piece of arc-shaped sheet, that is, the above-mentioned mold is used to manufacture a piece of arc-shaped sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com