Dual-motor power system

A power system, dual-motor technology, applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems of low braking energy recovery capacity, poor economy, high noise, etc., to simplify structure and function, reduce noise, etc. , the effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

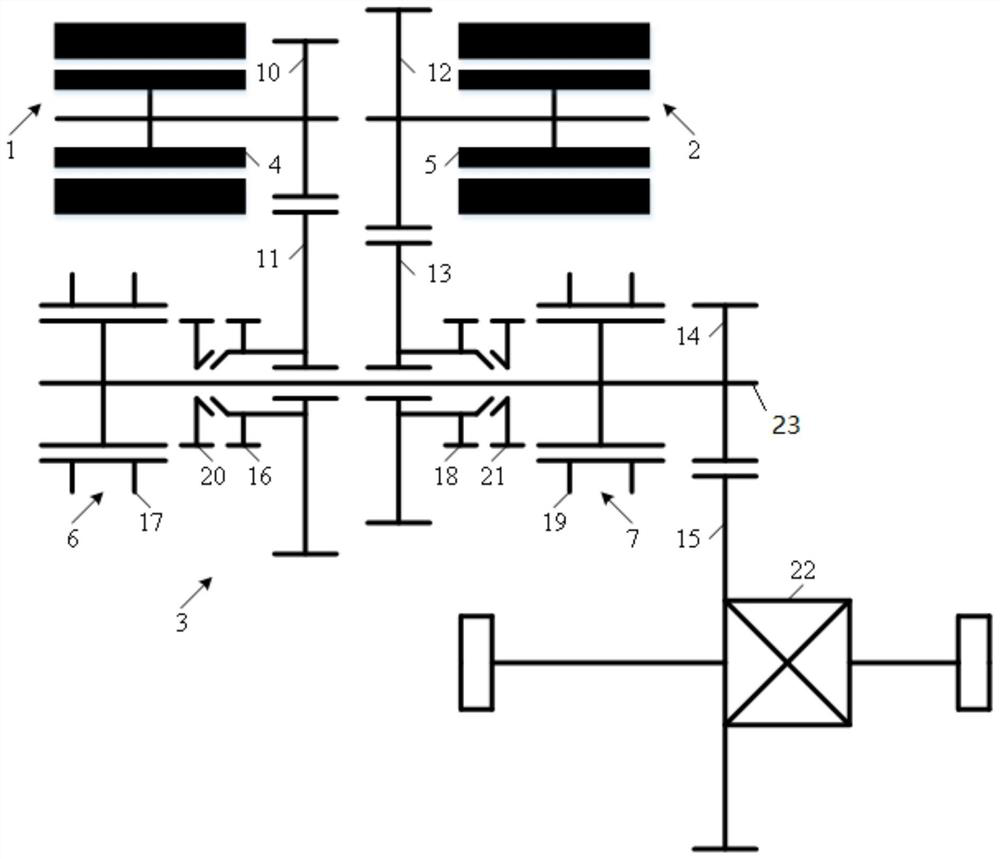

[0030] see figure 1 ,exist figure 1 The general arrangement of an embodiment of the dual-motor power system of the present invention is exemplarily shown in FIG. like figure 1 As shown, the dual motor power system of the present invention includes a first motor 1 , a second motor 2 and a transmission 3 .

[0031] Wherein, the first motor 1 and the second motor 2 are the power sources of the dual-motor power system, and the dual-motor power system of the present invention can be powered by one of the motors or by the two motors at the same time.

[0032] Specifically, the first electric machine 1 has a first rotor 4 . The second electric machine 2 has a second rotor 5 . The transmission 3 has a first controllable torque transmission device 6 , a second controllable torque transmission device 7 , a first fixed shaft gear pair driving gear 10 , a first fixed shaft gear pair driven gear 11 , and a second fixed shaft gear pair The driving gear 12 , the driven gear 13 of the se...

Embodiment 2

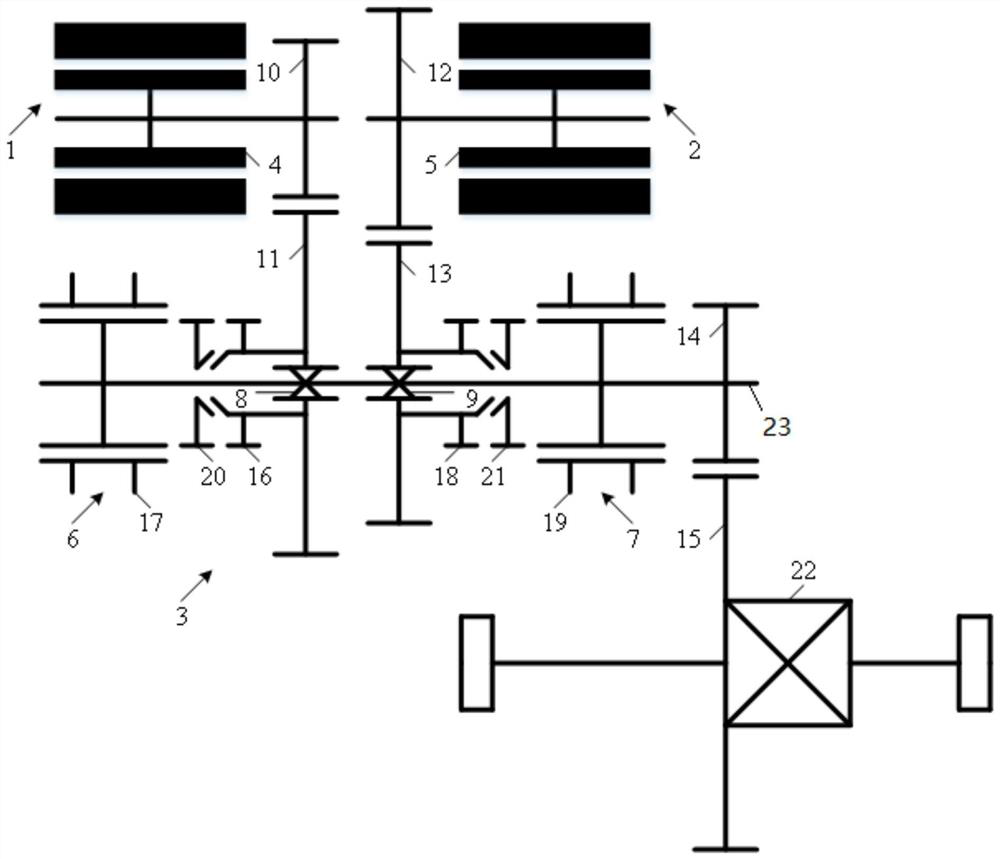

[0041] like figure 2 As shown, the second embodiment is basically the same as the first embodiment, except that the transmission 3 further includes a first one-way clutch 8 and a second one-way clutch 9 . One end of the first one-way clutch 8 is fixedly connected to the driven gear 11 of the first fixed shaft gear pair, and the other end is detachably connected to the transmission shaft 23 . The first fixed shaft gear pair driven gear 11 can transmit the forward output torque of the first motor 1 to the final drive gear 14 through the first one-way clutch 8 , and cannot output the reverse output of the first motor 1 Torque is transmitted to the final drive gear 14 through the first one-way clutch 8 . One end of the second one-way clutch 9 is fixedly connected to the driven gear 13 of the second fixed-shaft gear pair, and the other end is detachably connected to the transmission shaft 23 . The second fixed-shaft gear pair driven gear 13 can transmit the forward output torque...

Embodiment 3

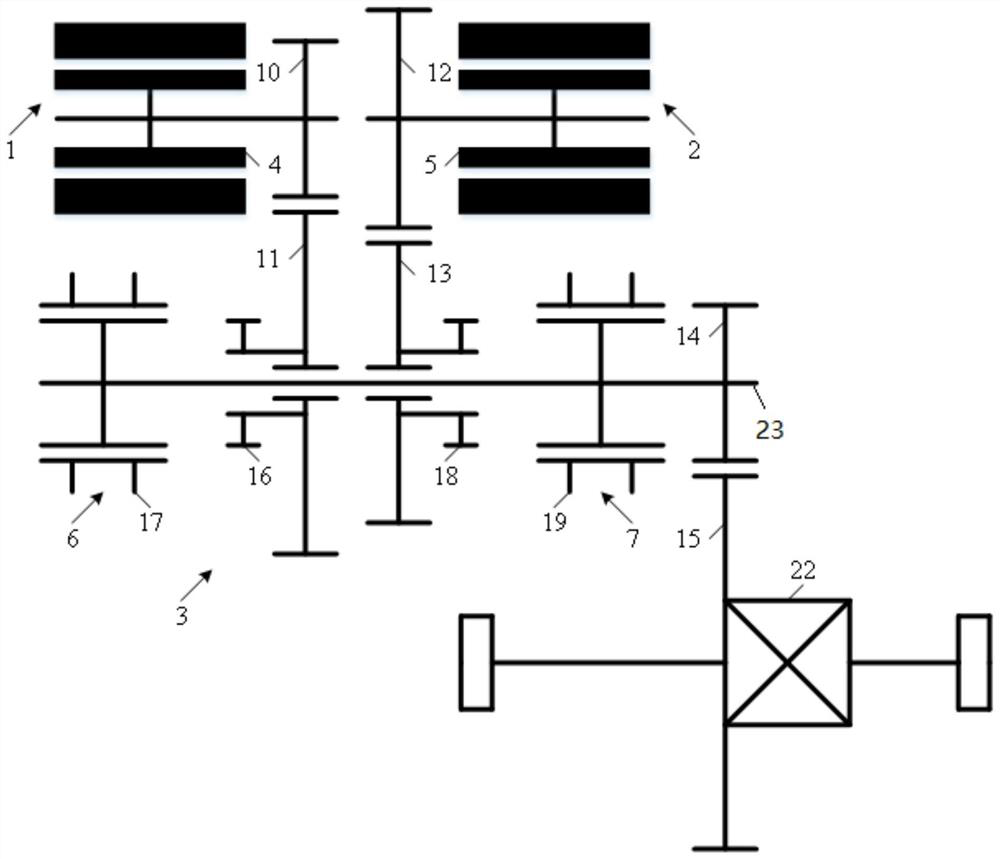

[0045] like image 3 As shown, the third embodiment is basically the same as the first embodiment, the difference is that the first controllable torque transmission device 6 is a claw clutch, which does not have the first lock ring 20; the second controllable torque transmission device 7 is Claw clutch, which does not have the second lock ring 21 .

[0046] Embodiment 3 Compared with Embodiment 1, the first controllable torque transmission device 6 and the second controllable torque transmission device 7 do not have lock rings, and do not rely on friction but on the precision of the first motor 1 and the second motor 2. Speed regulation realizes rotational speed synchronization between the first engagement portion 16 , the second engagement portion 17 , and between the third engagement portion 18 and the second engagement portion 19 , reducing wear and power loss, and reducing shift time .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com