Environment-friendly roadbed treatment method based on sponge city

A sponge city and treatment method technology, which is applied in the field of environmental protection roadbed treatment, can solve the problems of incomplete sponge city and ineffective interception of rainwater, etc., achieve remarkable interception effect, improve driving comfort, and meet the effect of foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

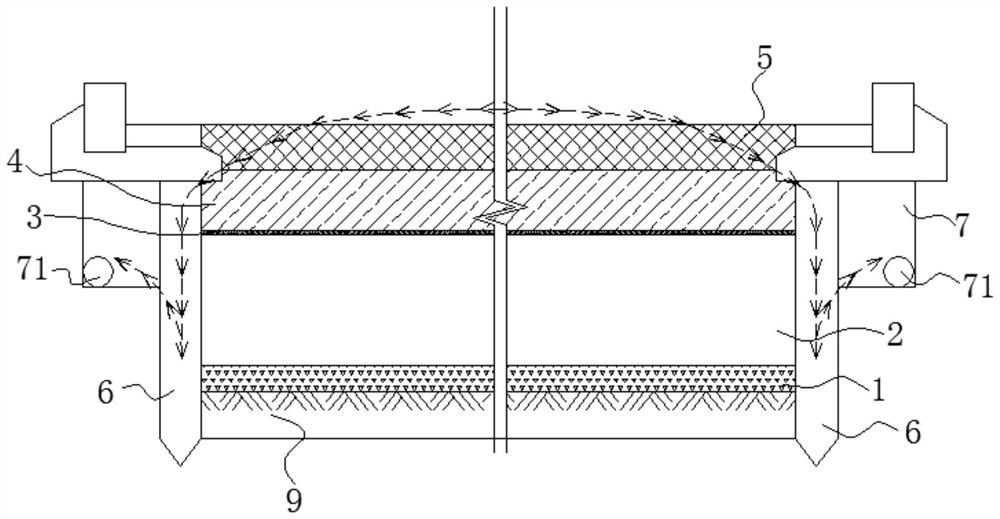

[0036] "W" type drainage for highway pavement (e.g. figure 1 , Figure 4 shown), its specific steps are as follows:

[0037] S1. Pavement layer treatment: The part above the top surface of the foundation is sequentially set with gravel cushion 1, dense base 2, waterproof sealing layer 3, permeable base 4, and asphalt permeable layer 5 to form the pavement structure. In addition, the permeable base layer 4 and the asphalt permeable layer 5 are both provided with cross slopes for guiding the seepage of rainwater on the road surface; wherein, the thickness of the crushed stone cushion layer 1 can be selected in the range of 30 to 50 cm, and the slope of the cross slope is 0.5% to 2%. , the specific selection depends on the actual situation, and the low point of the cross slope is located at the edge of the roadway, and the cross slope is symmetrically arranged on both sides of the road to collect water flow to the cross slope for drainage operation;

[0038] In this step, the t...

Embodiment 2

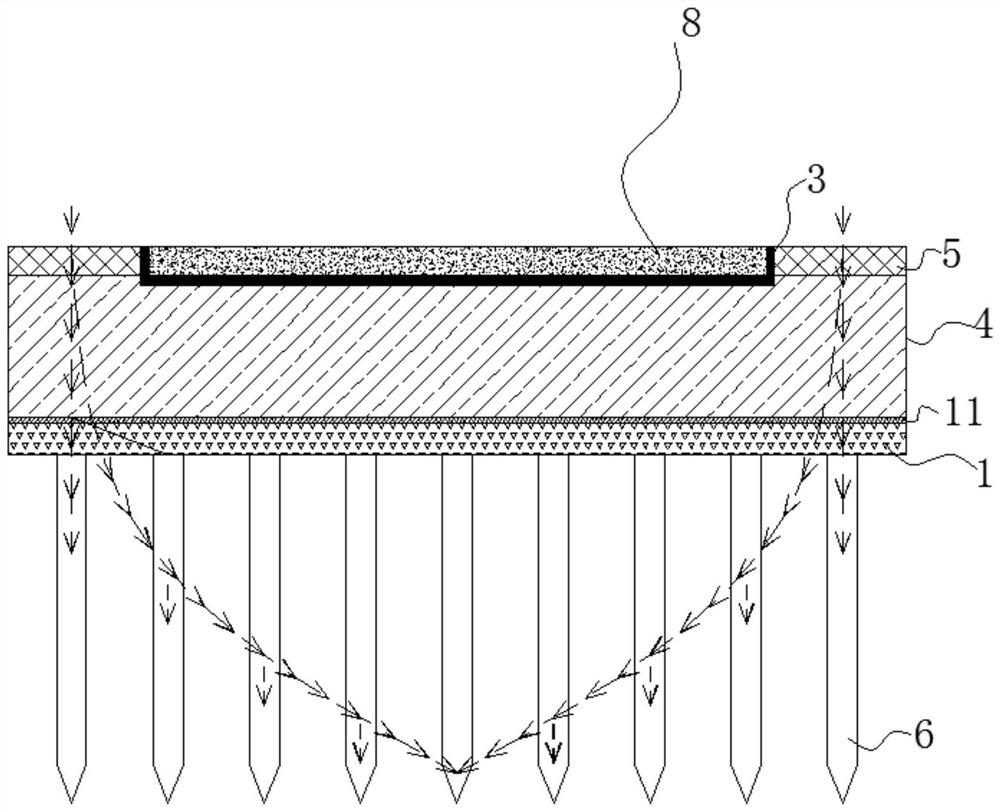

[0046] "V" type drainage method suitable for general buildings (such as figure 2 , Figure 4 shown), its specific steps are as follows:

[0047] S1, pile body construction: construct pile foundation at the road foundation place of structure 8, and pile cylinder 6 is driven into this pile foundation; The pile cylinder 6 of this step is identical with the structure in the embodiment one, do not repeat them here;

[0048] S2. Pavement layer treatment: The part above the top surface of the pile tube 6 is sequentially set with gravel cushion 1, permeable geotextile 11, permeable base 4, and asphalt permeable layer 5 to form the pavement structure, and in the middle of the pavement is the structure 8, and the structure 8. A waterproof sealing layer 3 is arranged around the structure to prevent the bottom layer of the structure from returning to moisture; the water flow through the water flow on both sides of the structure 8 in turn passes through the asphalt permeable layer 5, the...

Embodiment 3

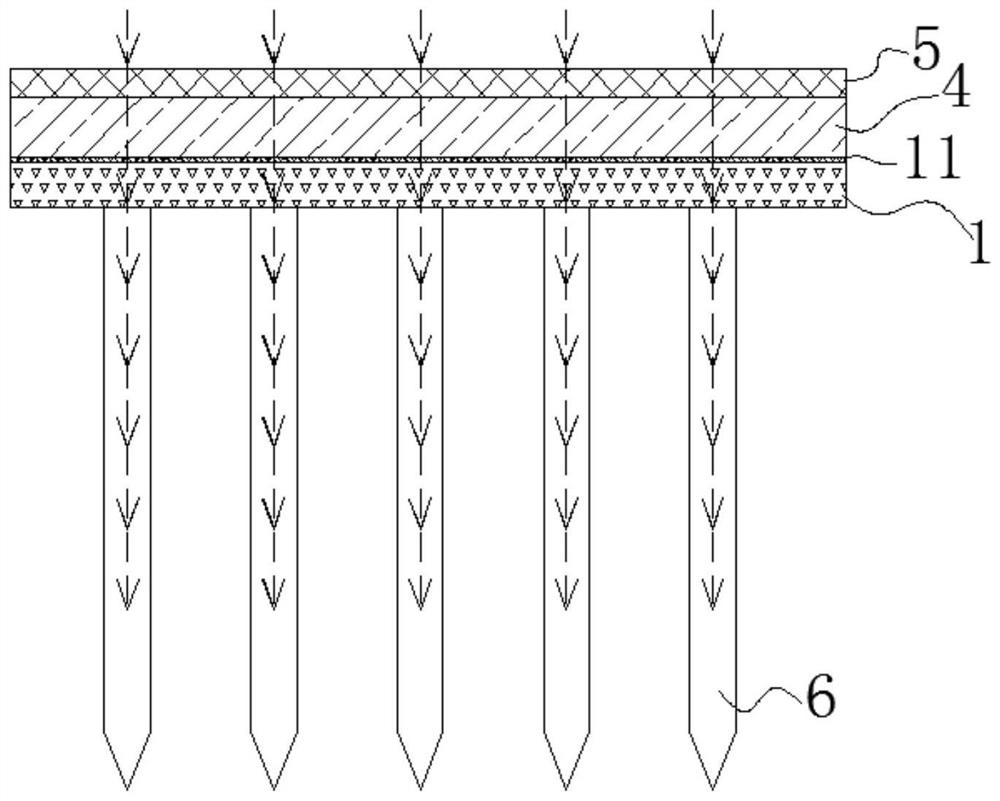

[0052] Sidewalks, squares, corridors and other fully permeable drainage types (such as image 3 , Figure 4 shown), the specific steps are as follows:

[0053] S1, pile body construction: construct the pile foundation at the roadbed, and drive the pile cylinder 6 into this pile foundation; the pile cylinder 6 of this step is identical with the structure in the embodiment one, and will not repeat them here;

[0054] S2. Pavement layer treatment: The part above the top surface of the pile tube (6) is sequentially provided with gravel cushion (1), permeable geotextile (11), permeable base layer (4), and asphalt permeable layer (5) from bottom to top to form the pavement structure ; The water flow direction of the pavement is formed from top to bottom to form a fully permeable drainage method for sidewalks, squares, corridors, etc. to be discharged to the municipal pipe network.

[0055] In this embodiment, there is no transverse slope on the road surface, so that rainwater seep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com