Construction method of T-shaped steel plate tie city wall

A construction method, steel plate technology, applied in the direction of building types, buildings, building maintenance, etc., can solve the problems of poor quality and safety, unstable stone walls, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

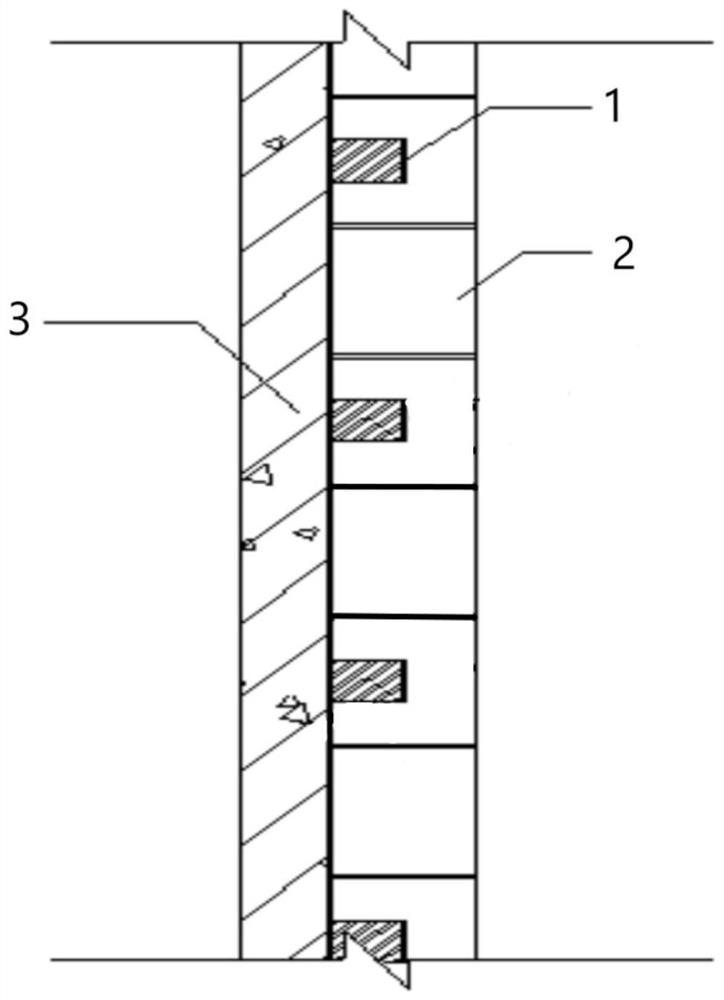

[0029] like figure 1 and Figure 5 As shown in the figure, a construction method of a T-shaped steel plate for pulling a city wall includes the following steps:

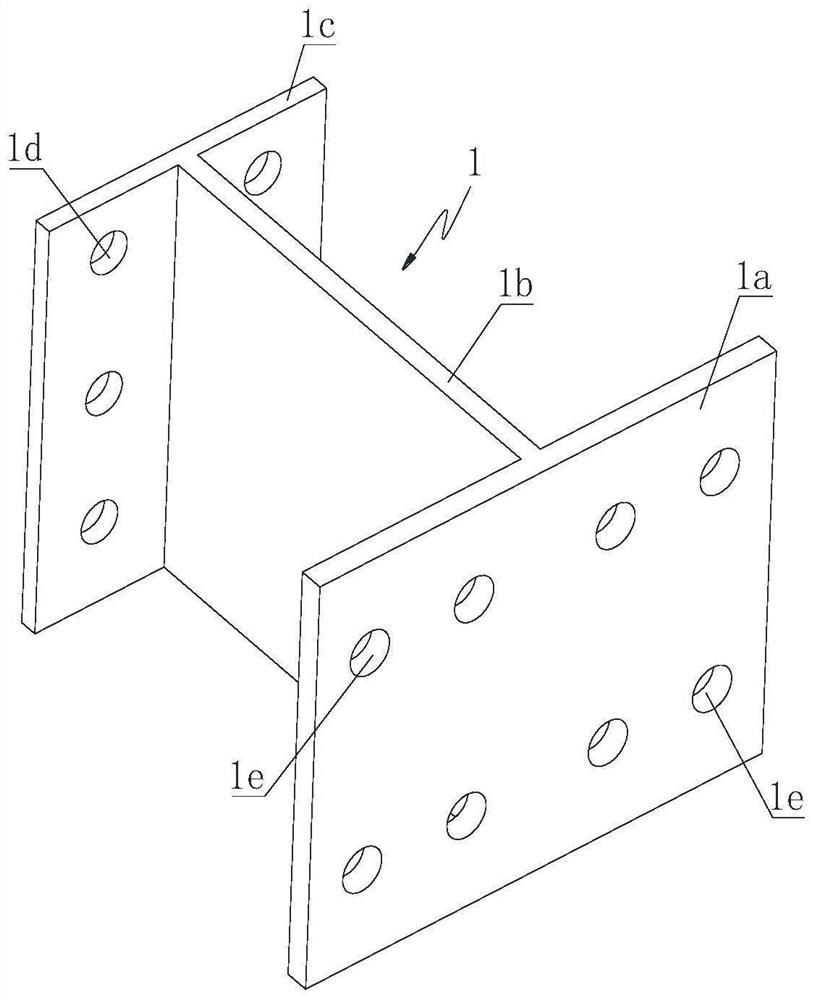

[0030] Step 1: Please refer to figure 2 , to make a T-tie steel plate 1. The T-tie steel plate 1 includes a web 1b and a wing plate 1a vertically connected to one end of the web 1b. In this embodiment, the thickness of the T-tie steel plate 1 is 15mm. The length of the plate 1b is 250mm, the length of the wing plate 1a is 200mm, and the height is 200mm.

[0031] Step 2: Cut the stone material 2 so that the grooved part of the stone material 2 is compatible with the wing plate 1a of the T-tie steel plate 1, and the inner size of the stone material 2 is slightly larger than the outer size of the wing plate 1a, so that the For stone 2 masonry installation and subsequent filling, the groove width is 40mm, the length is 120mm, and the height runs through the thickness direction of the entire stone 2.

[0032] Step 3:...

Embodiment 2

[0037] The difference between this embodiment and the first embodiment is that the inner wall 3 in step 3 is a new concrete wall. Specifically: when the new concrete wall is poured and constructed, metal welding parts are embedded in the position corresponding to the T-shaped tie steel plate 1, and the web 1b of the T-shaped tie steel plate 1 is fixedly connected to the metal welding parts by welding means to complete the T-shaped The fixing of the steel plate 1 and the inner wall 3.

Embodiment 3

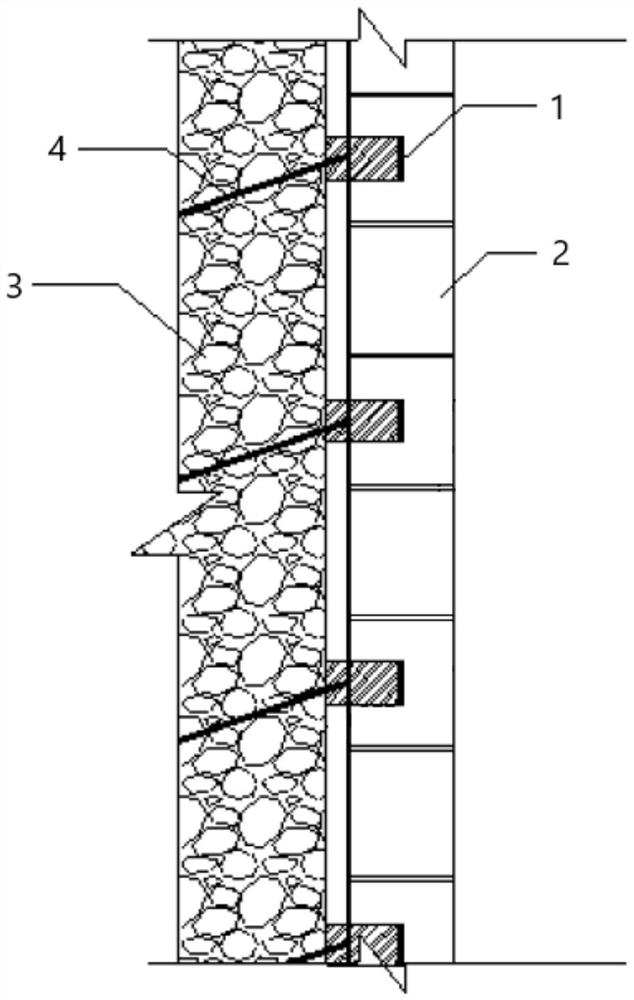

[0039] like image 3 and Figure 4 As shown, the difference between this embodiment and the first embodiment is that the inner wall 3 in step 3 is an earth wall, so it is necessary to embed the anchor rod 4 in the earth wall, and the end of the anchor rod 4 exposed to the earth wall is welded to the T-shaped The web 1b of the tie steel plate 1 is fixedly connected to complete the fixing of the T-shaped tie steel plate 1 and the inner wall 3 .

[0040] In order to increase the tensile force of the anchor rod 4, the anchor rod 4 is inclined and arranged in the earth wall. Specifically, the welding end of the anchor rod 4 and the web 1b is higher than the other end of the anchor rod 4, so that the installation method can make the T-tie knot. The steel plate 1 is more firmly fixed on the outside of the earth wall.

[0041] like Figure 5 As shown, two adjacent stone materials share a T-shaped tie steel plate 1, that is, the two ends of the T-shaped tie steel plate 1 wing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com