Protective isolation fence and processing method thereof

A technology of protection isolation and togetherness, applied to wire processing, other household appliances, building types, etc., can solve the problems of lack of protection, no protection, damage, etc., achieve good protection, enhance strength, and avoid attacks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

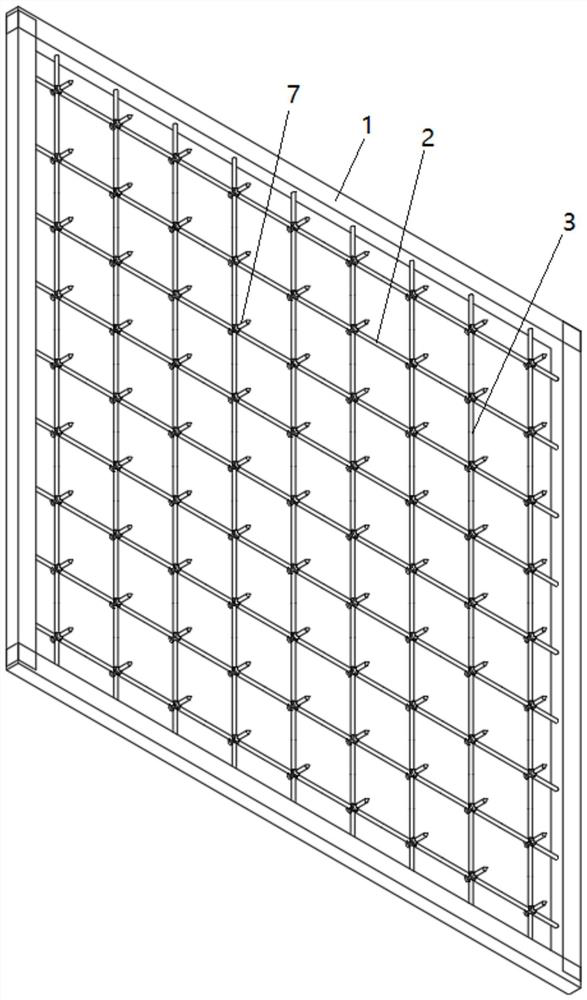

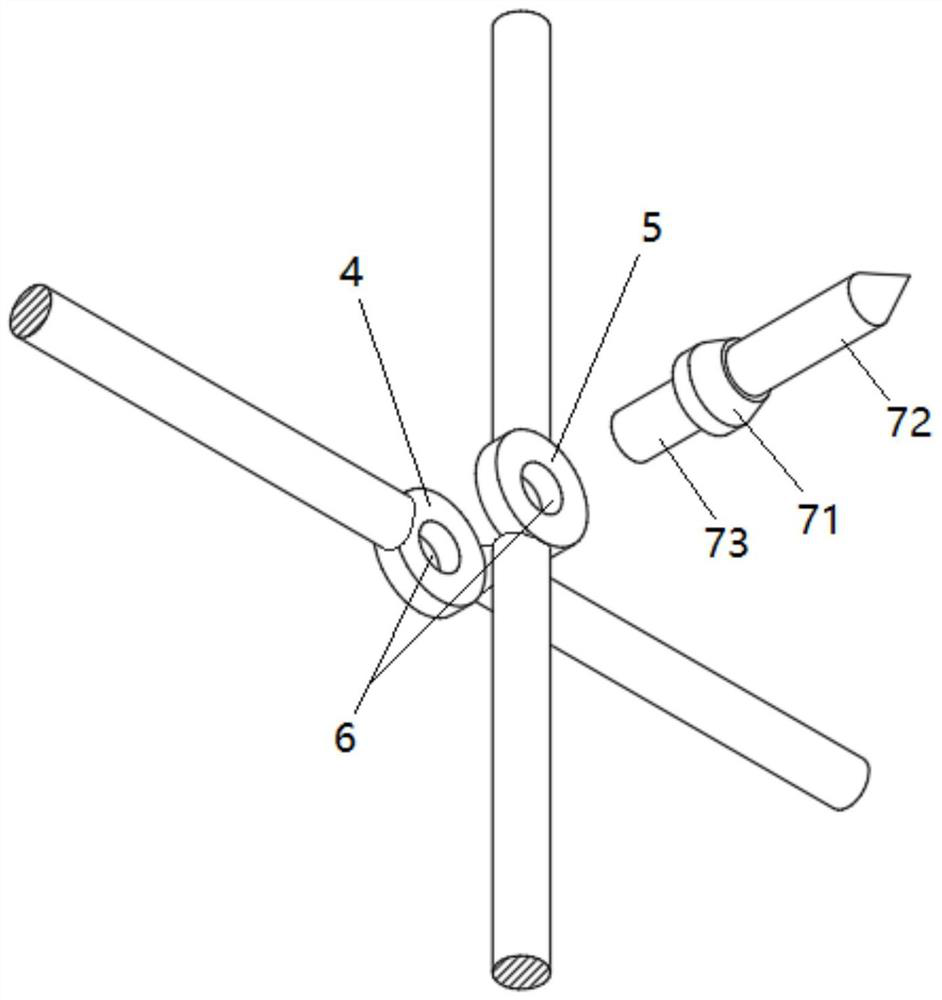

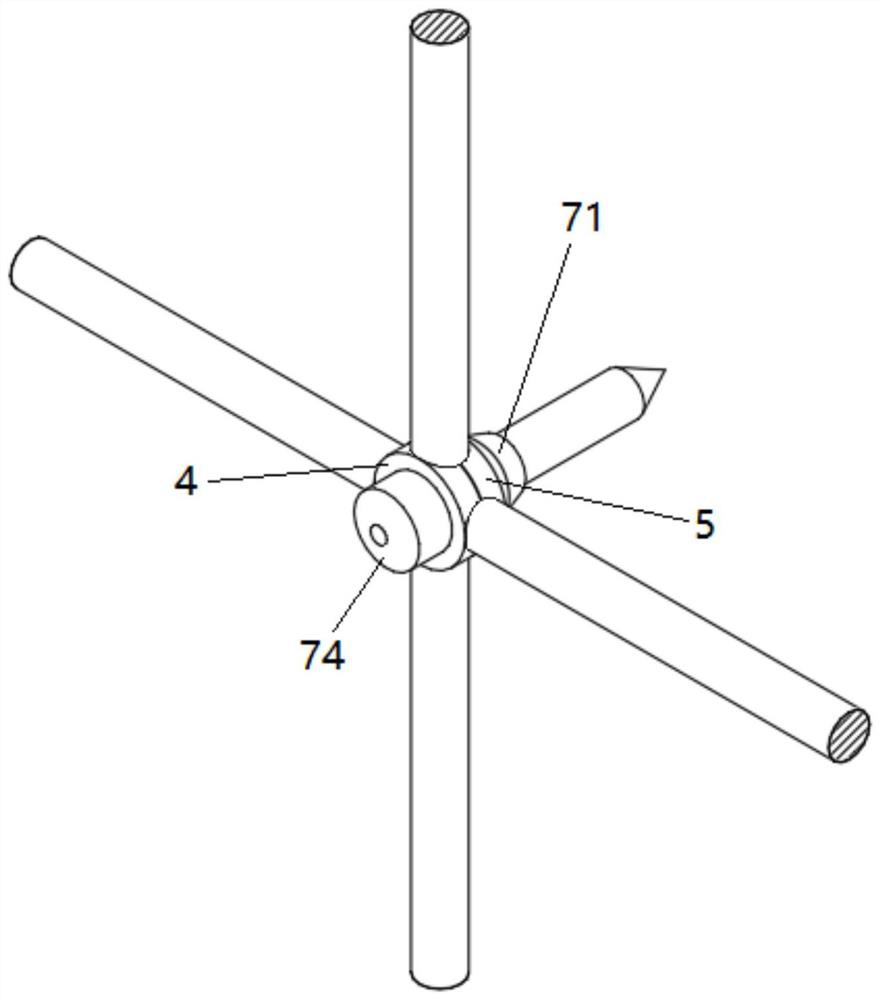

[0028] see Figure 1-3 , the present embodiment provides a protective isolation grille, including an outer frame 1 and a mesh fixed inside the outer frame, and the mesh includes a number of transverse reinforcement bars 2 and a number of longitudinal reinforcement bars 3 arranged in an intersecting manner. A first flat portion 4 and a second flat portion 5 are respectively formed at the intersecting portion of the steel bar and each longitudinal steel bar by punching, and the first flat portion 4 and the second flat portion 5 are provided with through holes 6 that communicate with each other. The barbed nails 7 penetrate through the through holes and extend out, and the first flat part 4 and the second flat part 5 are pressed together by riveting, so that several transverse steel bars 2 and several longitudinal steel bars 3 are fixedly connected.

[0029] In this embodiment, the inner edges of the four sides of the outer frame 1 are provided with a number of insertion holes (n...

Embodiment 2

[0037] see Figure 1-3 , this embodiment provides a processing method for a protective isolation barrier, which specifically includes the following steps:

[0038] S1. Use a stamping die to punch the intersecting parts of each transverse steel bar and each longitudinal steel bar to form the first flat part 4 and the second flat part 5 respectively, and at the same time, in the first flat part 4 and the second flat part 5 Through holes 6 are formed on both;

[0039] S2. Arrange several transverse reinforcing bars 2 and several longitudinal reinforcing bars 3 in an intersecting manner, so that the first flat portion 4 and the second flat portion 5 are aligned together;

[0040] S3. Insert the thorn 7, that is, the insertion portion 73 into the through hole and extend out, use a riveting machine to rive the thorn 7, and press the first flat portion 4 and the second flat portion 5 together, so that several A horizontal steel bar 2 is fixedly connected with a number of longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com