Test system and method for dynamic impact mechanical performance test of light aircraft structure

A technology of light aircraft and impact mechanics, which is applied in the field of test systems for dynamic impact mechanical performance testing of light aircraft structures, can solve the problems of loading and testing of the test system that cannot meet the requirements of general light aircraft overall impact test tests, and neglect the aircraft body, etc. To achieve the effect of high reliability, firm clamping and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

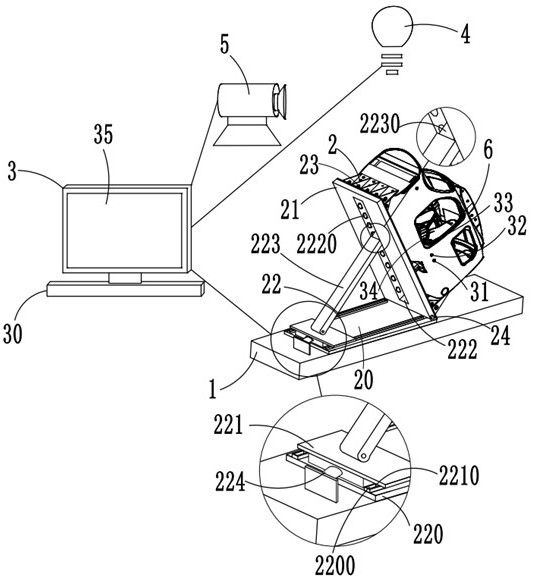

[0037] like figure 1 As shown, the test system for the dynamic impact mechanical performance test of light aircraft structure includes a trolley 1, a test fixture 2, a measurement control assembly 3, a lighting assembly 4 for providing illumination for the test system, a camera measurement assembly 5, and a test The light aircraft test piece 6 on the fixture 2, and an aviation dummy is placed in the light aircraft test piece 6;

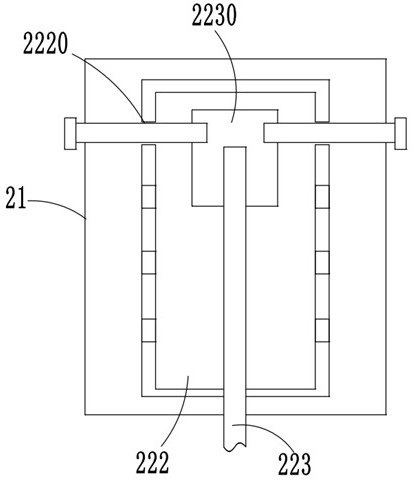

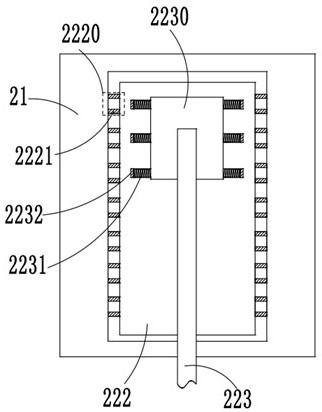

[0038] The test fixture 2 includes a lower connection panel 20 arranged on the upper end of the trolley 1, an upper connection panel 21 hinged to one end of the lower connection panel 20, an angle adjustment bracket assembly 22 arranged between the upper connection panel 21 and the lower connection panel 20, The fuselage connecting mechanism 23 is arranged on the upper end of the upper connecting panel 21, and the light aircraft test piece 6 is installed on the upper end of the upper connecting panel 21 through the fuselage connecting mechanism 23;

...

Embodiment 2

[0047] This embodiment differs from Embodiment 1 in that:

[0048] like Figure 5 As shown, the opposite sides of the two clamping top blocks 235 are V-shaped.

Embodiment 3

[0050] This embodiment differs from Embodiment 1 in that:

[0051] like Image 6 As shown, opposite sides of the two clamping top blocks 235 are U-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com