Underwater ball valve load simulation device and underwater ball valve execution mechanism test method

An actuator and load simulation technology, applied in the testing of machine/structural components, measuring devices, mechanical valve testing, etc., can solve the problems of large-diameter deep-water ball valves, such as bulky volume and complicated testing process, and achieve a large hydraulic power-to-weight ratio, The effect of simplifying the test process and the overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

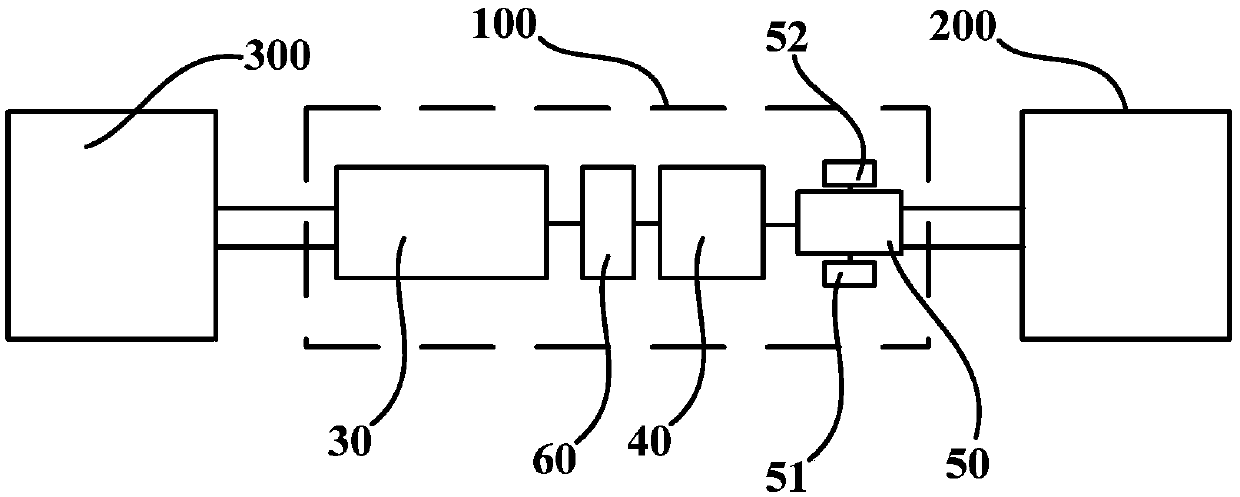

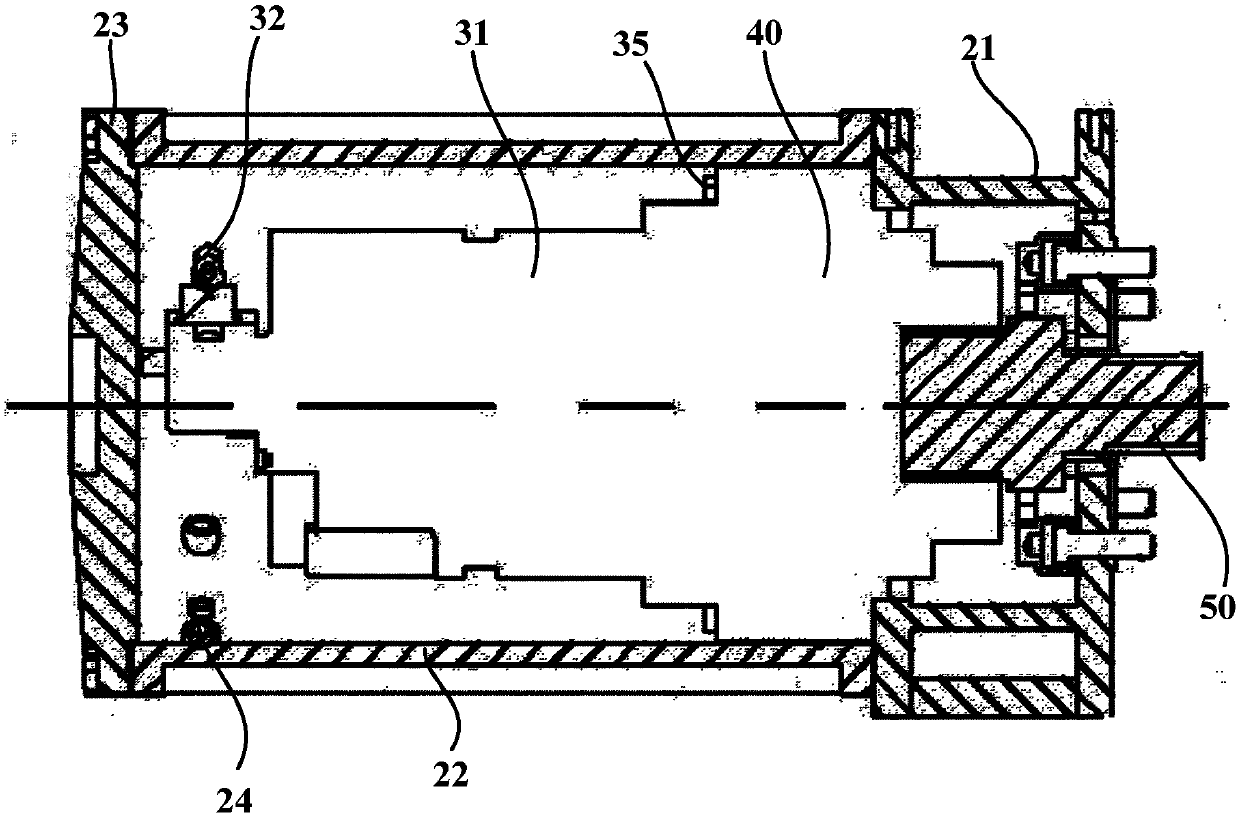

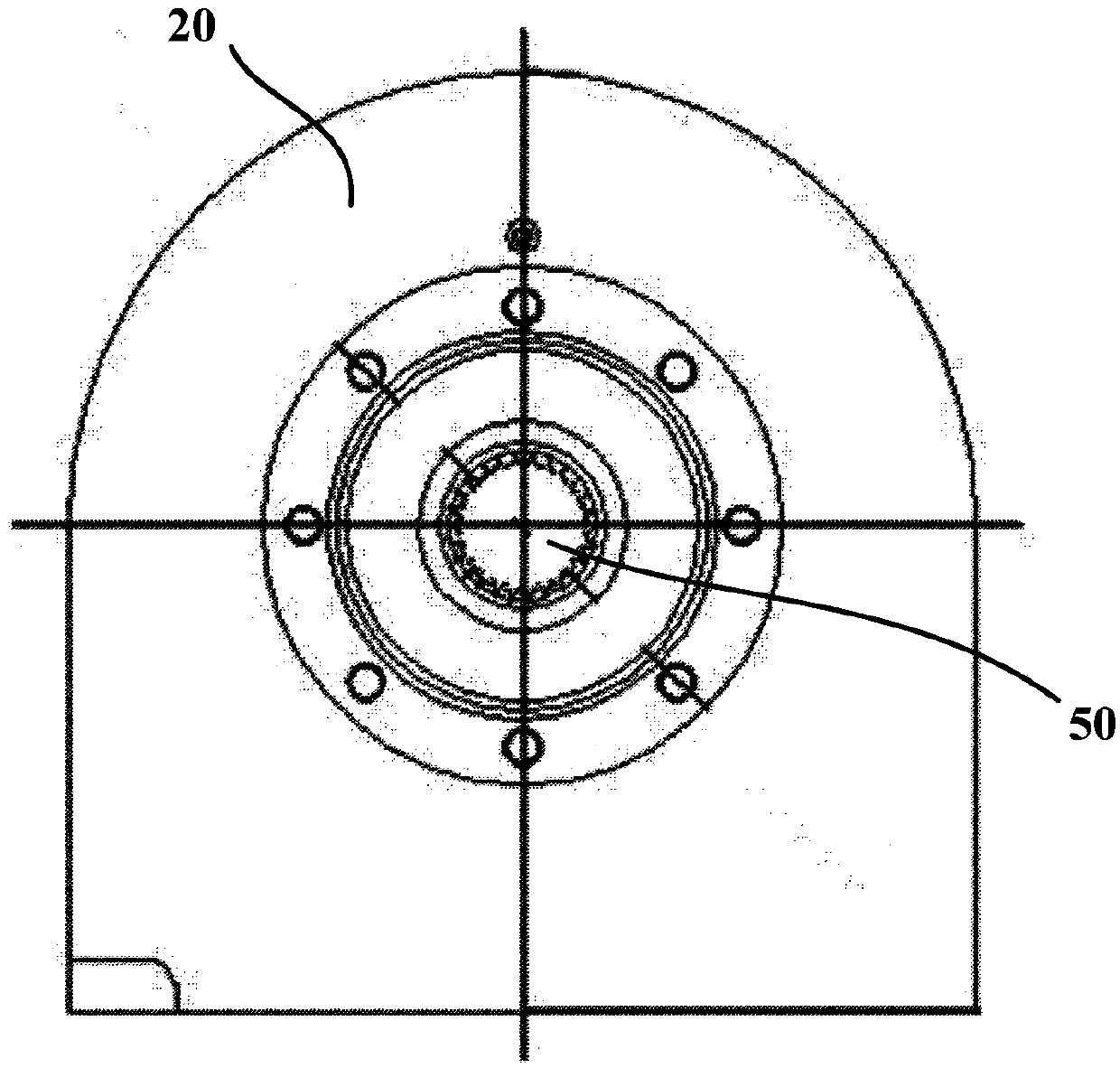

[0038] figure 1 and figure 2 They are respectively a schematic block diagram and a schematic structural diagram of an underwater ball valve load simulation device according to an embodiment of the present invention. Such as figure 1 and figure 2 shown, and refer to image 3 , the embodiment of the present invention provides an underwater ball valve load simulation device 100 , and the underwater ball valve load simulation device 100 is used for testing the underwater ball valve actuator 200 . Specifically, the underwater ball valve load simulation device 100 includes a sealed housing 20 , a hydraulic motor device 30 , a speed reducer 40 and a spline drive shaft 50 . The inside of the sealed housing 20 is a pressure-resistant sealed cavity for underwater pressure-resistant sealing, and the sealed housing 20 is provided with a shaft hole. The hydraulic motor device 30 is disposed in the pressure-resistant sealed cavity and fixed to the sealed housing 20 . The hydraulic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com