Plastic steel air duct flange machining device and machining method

A processing device and processing method technology, applied in the field of plastic steel air duct flange processing device, to achieve the effects of high precision, avoiding stress concentration, processing cost and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

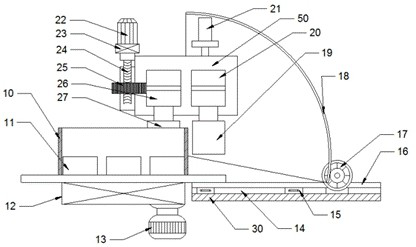

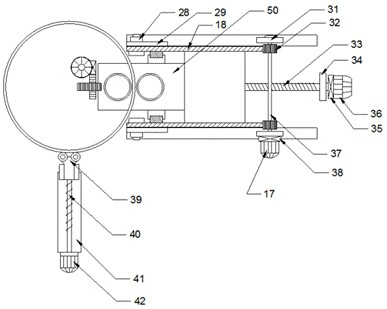

[0041] see attached Figure 1-5 , the fixing component includes a workpiece clamping bracket, a quick chuck 11, a spindle reducer 12 and a first servo motor 13, the annular workpiece 10 is fixed on the workpiece clamping bracket through the quick chuck 11, and the workpiece clamping bracket is passed through the main shaft. The reducer 12 is connected with the first servo motor 13, and the first servo motor 13 controls the rotation and movement of the annular workpiece 10 through the spindle reducer 12 and the quick chuck 11;

[0042] The clamping assembly includes a fixed roller subassembly, a moving roller subassembly, a main fixing table 50 and a lifting cylinder 21;

[0043]The fixed roller sub-assembly includes a fixed bottom roller 19, a fixed shaft block 20, a first ball screw 33, a fourth bracket 34, a fourth planetary reducer 35 and a fourth servo motor 36. The fixed bottom roller 19 is arranged in a fixed position. On the shaft block 20, the fixed shaft block 20 is ...

Embodiment 2

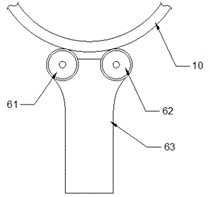

[0065] see Figure 6-8 , Image 6 It is a sectional view of the plastic-steel air duct flange processing device according to the embodiment of the present invention Figure 1 , the state of the preparatory work completed before flanging; Figure 7 It is a sectional view of the plastic-steel air duct flange processing device according to the embodiment of the present invention Figure II , complete the state of flanging; Figure 8 It is a sectional view of the plastic-steel air duct flange processing device according to the embodiment of the present invention Figure 3 , after the flanging is completed, the metal sheet ring returns to its original position.

[0066] Specifically, the plastic-steel air duct flange processing device includes a fixing fixture 70, a flanging portion 80 and a power supply system;

[0067] The fixing fixture 70 is used to fix the end of the air duct to be flanged, and the inner circumference of the fixing fixture 70 includes an arc portion 701 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com