Feeding control method and system for thin-plate cut-tobacco drier

A thin plate shred drying machine and control method technology, applied in the field of cut tobacco production, can solve problems such as frequent start and stop of equipment, material blockage, etc., achieve the effect of improving service life and working efficiency, and reducing broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

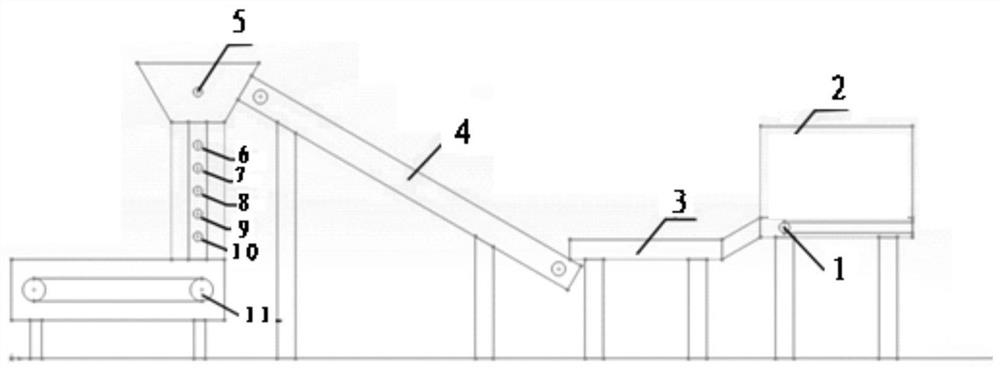

[0034] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0035] In view of the problem that the current thin-plate drying machine is prone to material blockage during feeding, causing the equipment to start and stop frequently. The invention provides a feeding control method and system for a thin-plate drying machine, which solves the problem of frequent starting and stopping of the equipment due to material blockage in the limit pipe when feeding the existing thin-plate drying machine, and can improve the service life of the equipment And work efficiency, reduce the shredding rate of shredded tobacco.

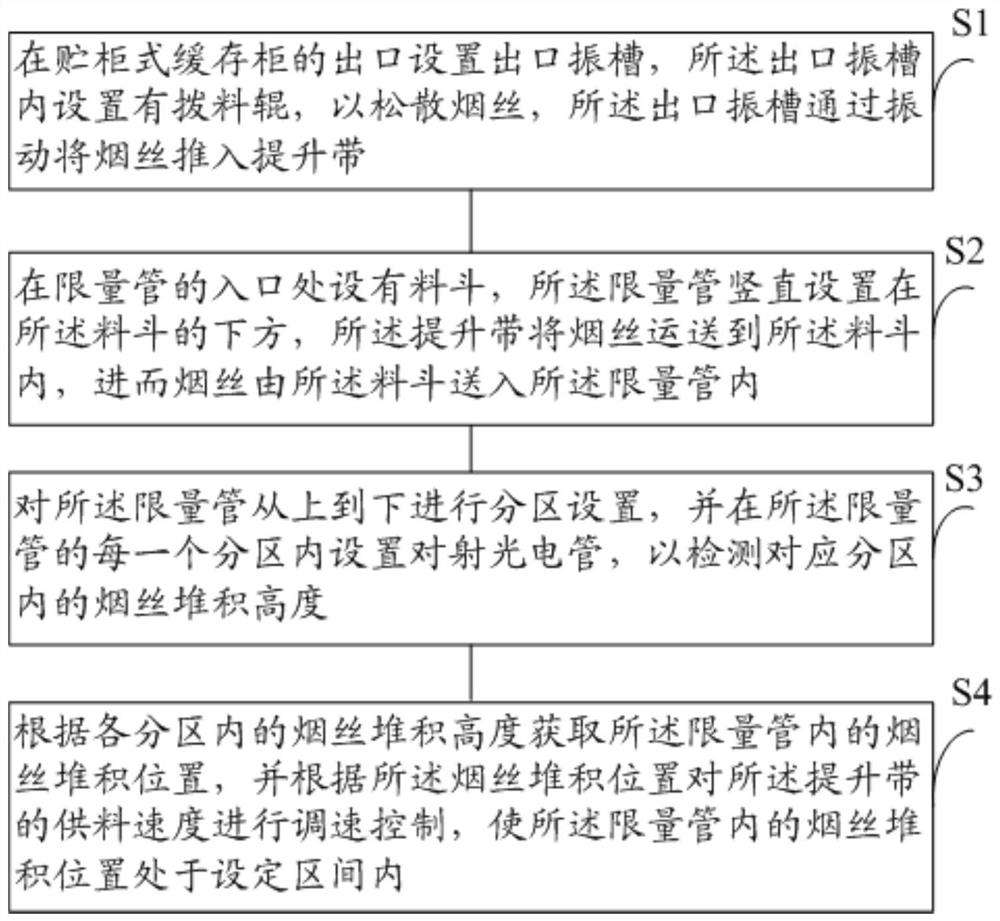

[0036] like figure 1 As shown, a feed control method for a thin-plate drying machine includes:

[0037] S1: an outlet vibrating groove is arranged at the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com