Novel hair drier based on hollow cup high-speed motor and use method of novel hair drier

A high-speed motor and hair dryer technology, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the diameter of the air outlet cannot be well adjusted, so as to improve the experience and controllability. The effect of reducing the output air volume and ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

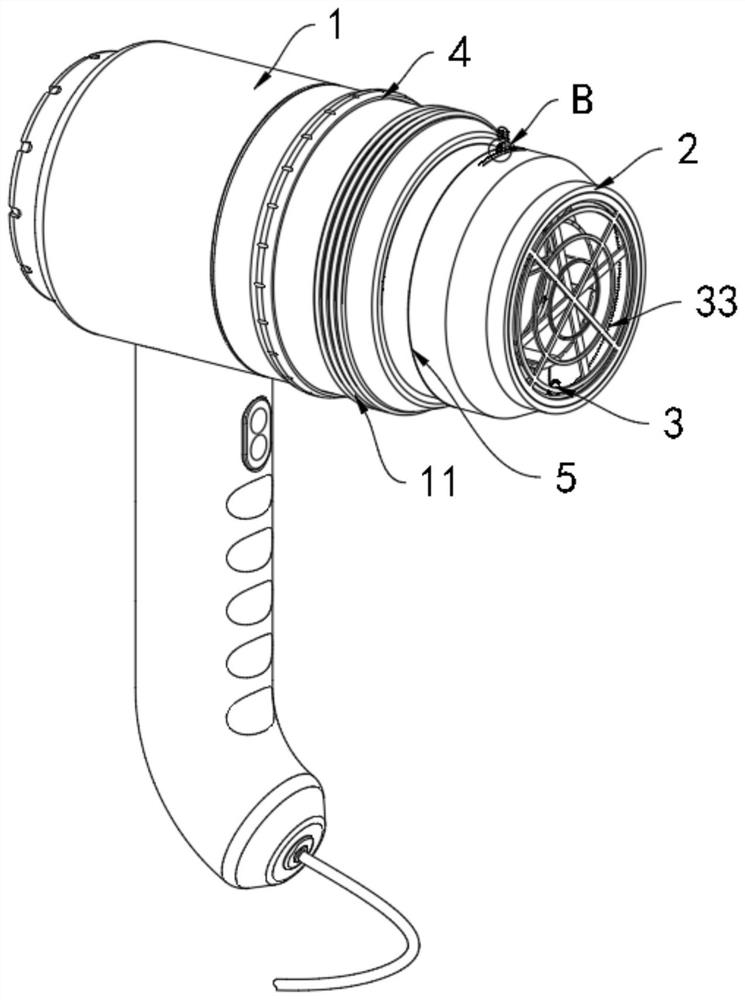

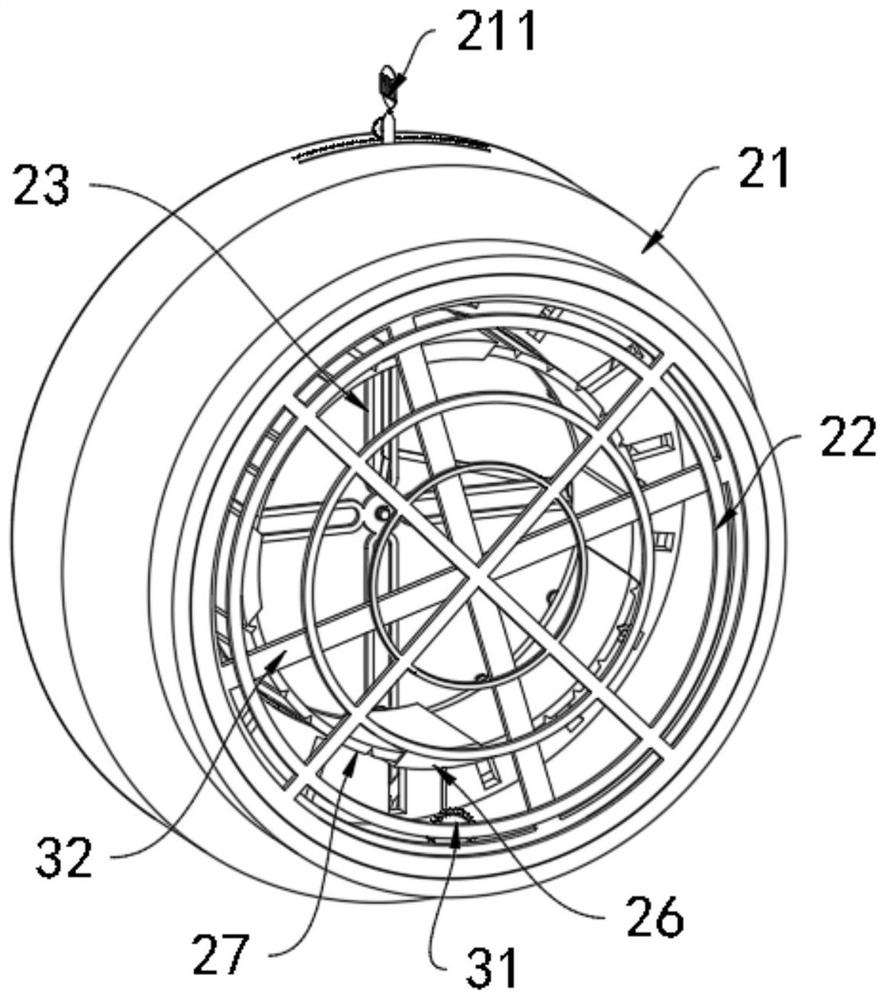

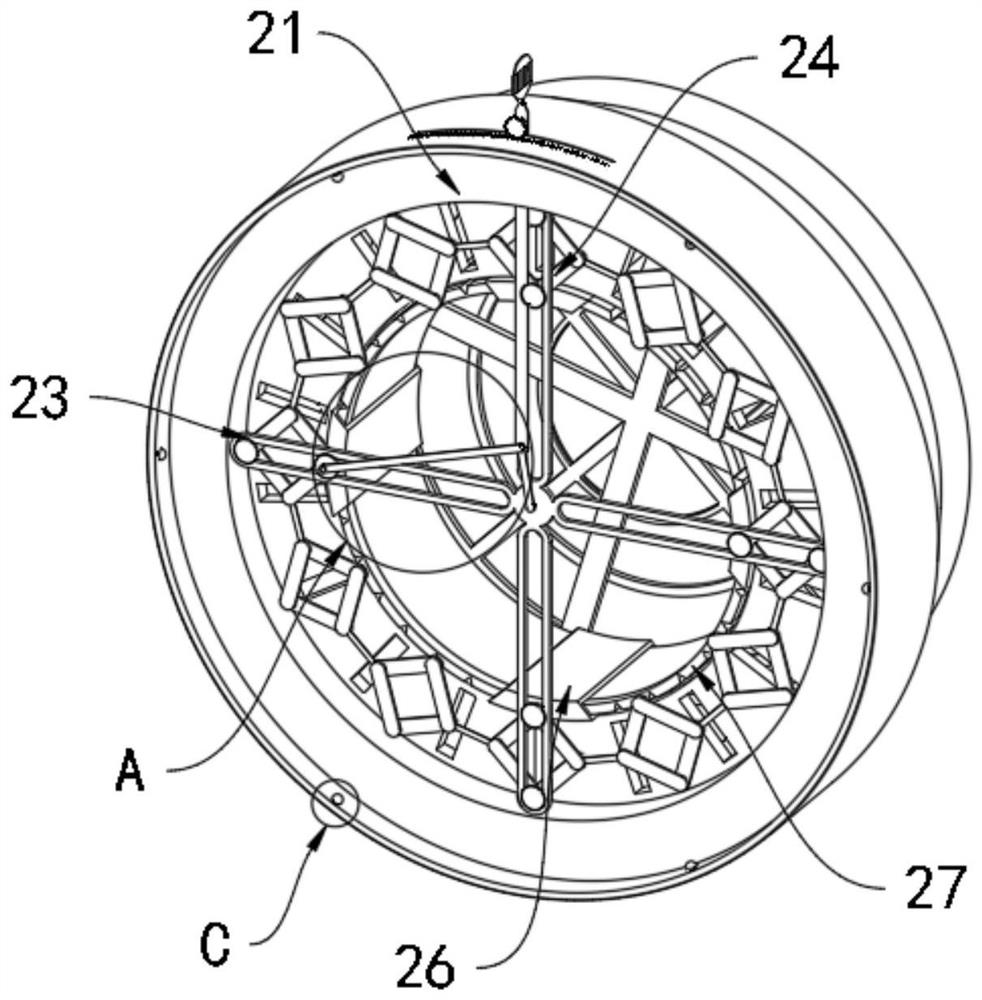

[0050] Please refer to Figure 2 to Figure 6 As shown, a new type of hair dryer based on a hollow cup high-speed motor includes a hair dryer main body 1, an air outlet end 11, and a heating wire 12. The right side of the hair dryer main body 1 is provided with an air outlet end 11, and the outer surface of the air outlet end 11 is provided with an air outlet end 11. There is a threaded connection part, an electric heating wire 12 is installed inside the main body 1 of the hair dryer, and an independent adjustment mechanism 2 of the air outlet is arranged on the right side of the air outlet 11. Chute frame 23, square hinge ring 24, driven strip 25, adjusting cavity plate 26, wrinkled elastic sheet 27, active dial 28, arc chute 1 29, limiting gear 210, rack 211, air outlet 11 An air guide duct 21 is provided on the outside of the right side, and a dust-blocking net 22 is installed on the right side of the air guide duct 21. The interior of the air guide duct 21 is fixedly connec...

Embodiment 2

[0053] Please refer to figure 1 and Figure 7 to Figure 8 As shown, a new type of hair dryer based on a hollow cup high-speed motor includes a hair dryer main body 1, an air outlet end 11, and a heating wire 12. The right side of the hair dryer main body 1 is provided with an air outlet end 11, and the outer surface of the air outlet end 11 is provided with an air outlet end 11. There is a threaded connection part, an electric heating wire 12 is installed inside the main body 1 of the hair dryer, and an active auxiliary heat dissipation mechanism 4 is arranged on the inner wall of the main body 1 of the hair dryer. The second groove 43, the connecting slider 44, the main swivel 45, and the first drain hole 46, the inner wall of the main body 1 of the hair dryer is fixedly connected with a circular cavity 41, and the circular cavity 41 is a circular cavity structure, and the inner wall of the circular cavity 41 is fixedly connected. A leak hole 46 is evenly opened at the botto...

Embodiment 3

[0056] Please refer to Figure 1 to Figure 10 As shown, a new type of hair dryer based on a hollow cup high-speed motor includes a hair dryer main body 1, an air outlet end 11, and a heating wire 12. The right side of the hair dryer main body 1 is provided with an air outlet end 11, and the outer surface of the air outlet end 11 is provided with an air outlet end 11. There is a threaded connection part, through the provided threaded connection part, it is convenient for the user to connect the main body 1 of the hair dryer to other supporting components, and the main body 1 of the hair dryer is installed with an electric heating wire 12. The electric heating wire 12 is shown as a hollow cup high-speed motor hair dryer Internal heating components;

[0057] On the right side of the air outlet 11 is an air outlet self-adjusting mechanism 2. The air outlet self-adjusting mechanism 2 includes an air guide duct 21, a dust-blocking net 22, a cross slot frame 23, a square hinge link 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap