Pharmaceutical oscillating granulator with material guiding function

A swinging granulator and granulator technology are applied in the direction of granulation of vibration devices, making medicines into special physical or ingestible devices, etc., which can solve the problems of console failure, material collection influence, lack of barrel fixation, etc., and achieve Improve processing efficiency, avoid blockage, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

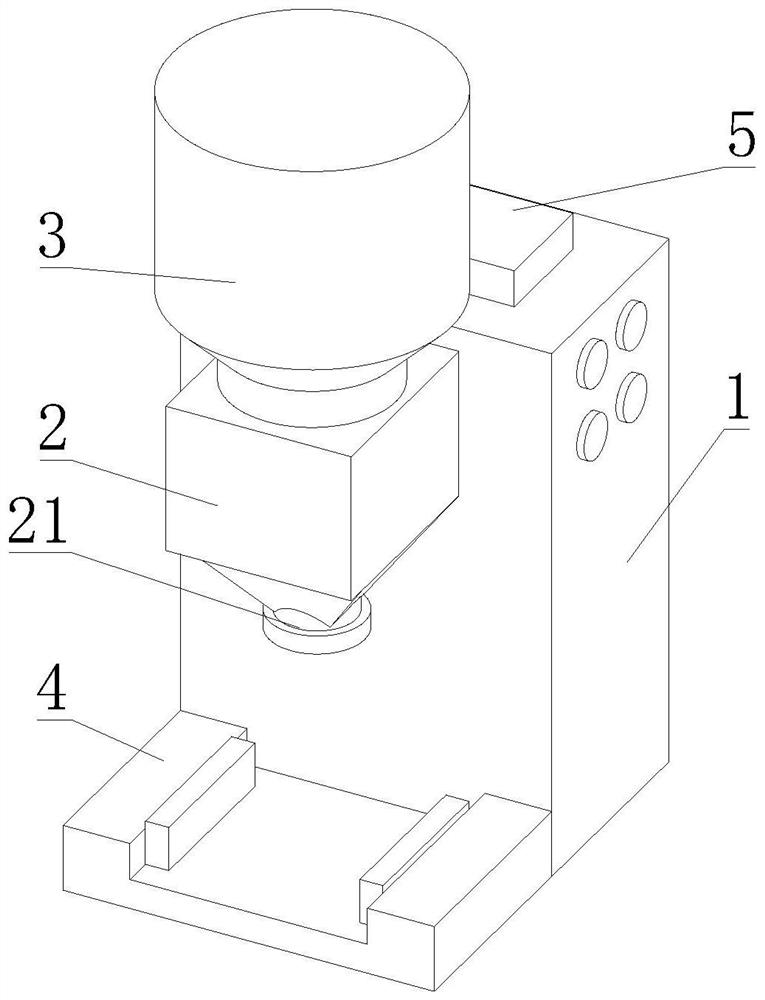

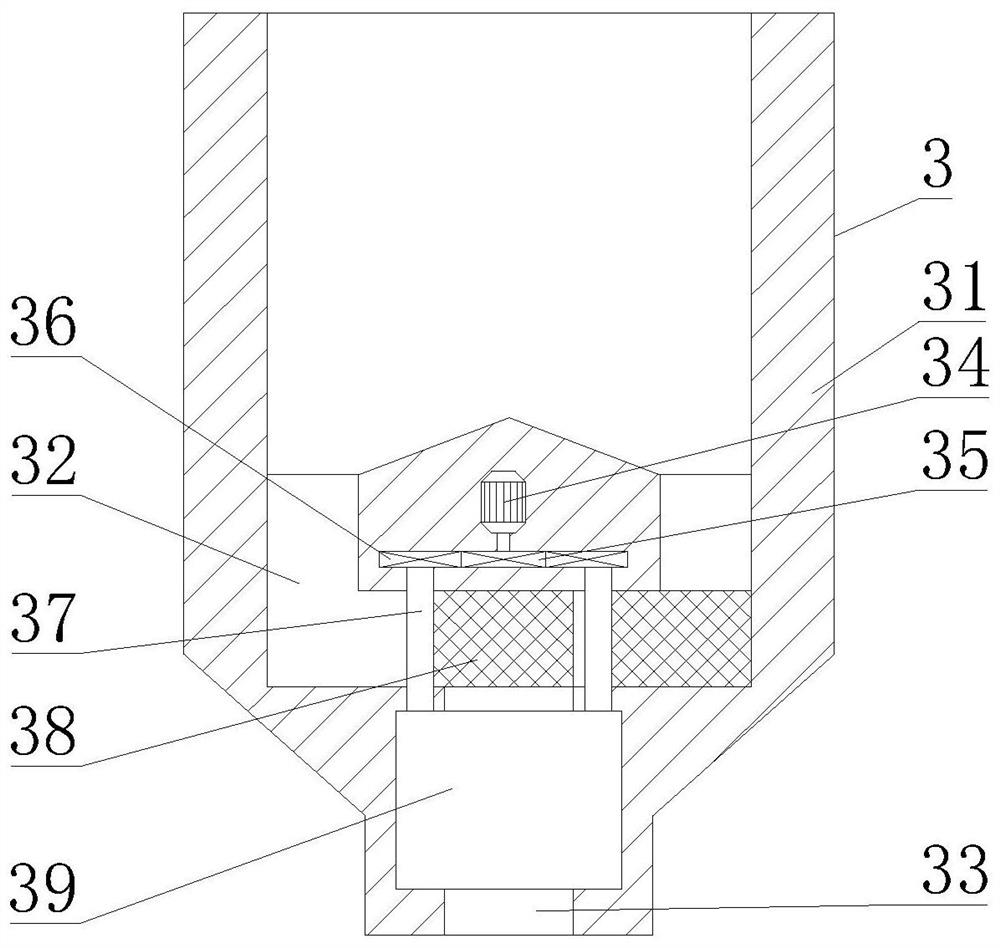

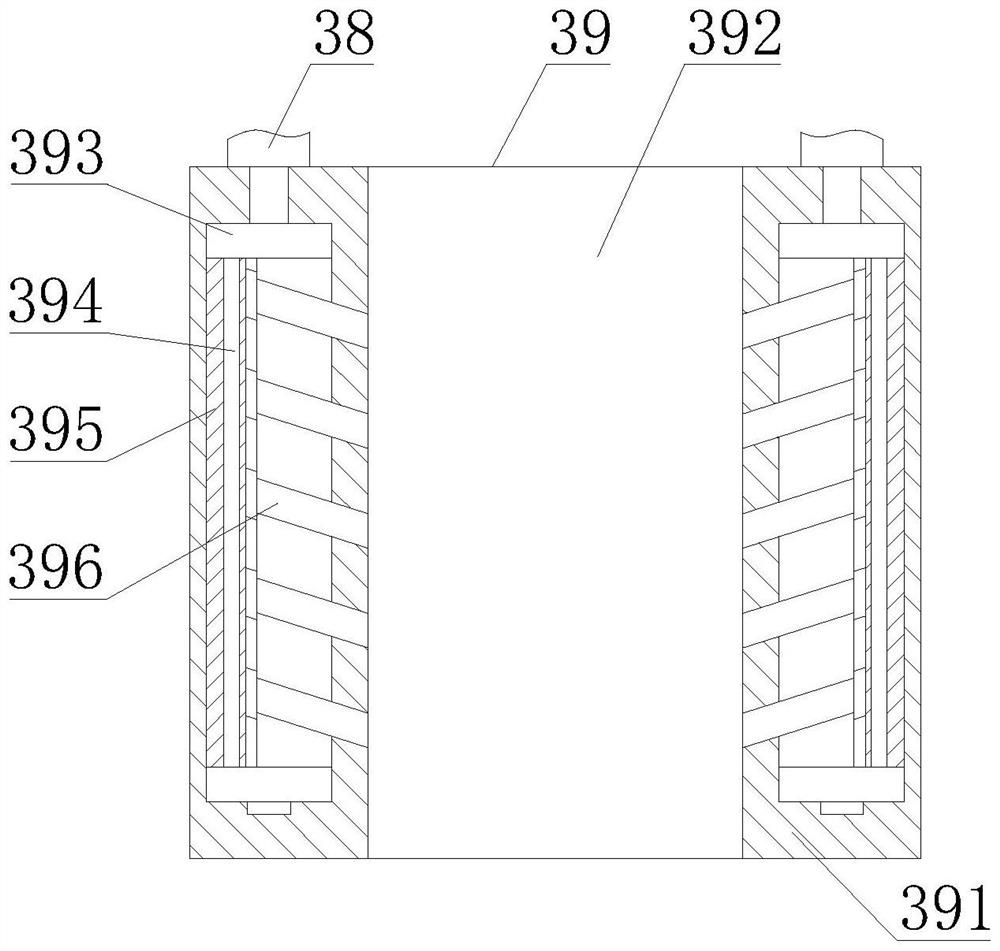

[0039] like Figure 1-6As shown, the present invention provides a pharmaceutical swinging granulator with a feeding function, comprising a console 1, a granulator body 2 is fixedly connected to the top of the front end of the console 1, and a discharge pipe is fixedly connected to the bottom end of the granulator body 2 21. The top of the pellet machine main body 2 is fixedly connected with a feeding bucket 3, the bottom end of the console 1 is fixedly connected with a fixed base 4, and the top of the console 1 is fixedly connected with a heat dissipation mechanism 5. The feeding bucket 3 includes a hopper 31, and the hopper 31 is fixed Connected to the top of the pellet machine main body 2, the middle of the hopper 31 is provided with a feeding groove 32, the bottom end of the hopper 31 is provided with a discharge groove 33, the middle of the hopper 31 is fixedly connected with a first motor 34, the output shaft of the first motor 34 A driving wheel 35 is fixedly connected, ...

Embodiment 2

[0042] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the fixed base 4 includes a connection base 41, the connection base 41 is fixedly connected to the bottom end of the console 1, and the middle of the connection base 41 is provided with The slot 42 is placed, the second motor 43 is fixedly connected to the inner two sides of the connecting seat 41, the output shaft of the second motor 43 is fixedly connected with a threaded rod 44, and the side of the threaded rod 44 is threadedly connected with a threaded slider 45. The threaded slider The side of 45 is movably connected with the ejector rod 46, and one end of the ejector rod 46 is movably connected with a fixed plate 47, which is movably connected to the side of the placement slot 42, and the fixed plate 47 includes a plate body 471, and the plate body 471 is movably connected to the ejector rod. At one end of 46, a top block 472 is movably connect...

Embodiment 3

[0045] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the heat dissipation mechanism 5 includes a heat dissipation box 51, the heat dissipation box 51 is fixedly connected to the top of the console 1, and the inner two sides of the heat dissipation box 51 are opened There is an exhaust hole 52, an air intake hole 53 is opened in the inner center of the heat dissipation box 51, a fan 54 is fixedly connected to the bottom end of the inner wall of the exhaust hole 52, and a dustproof net 55 is fixedly connected to the top of the heat dissipation box 51. A heat-absorbing plate 56 is fixedly connected inside, a heat-dissipating fin 57 is fixedly connected to the side of the heat-absorbing plate 56 , and a semiconductor refrigeration fin 58 is fixedly connected to the inside of the heat-dissipating box 51 , and one end of the semiconductor refrigeration fin 58 extends to the inside of the exhaust hole 52 . , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com