Stirring device of compound oil phase reaction kettle

A technology of stirring device and composite oil phase, which is applied to mixers with rotating stirring devices, feeding devices, mixer accessories, etc., which can solve the problems of blocking the feeding port and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

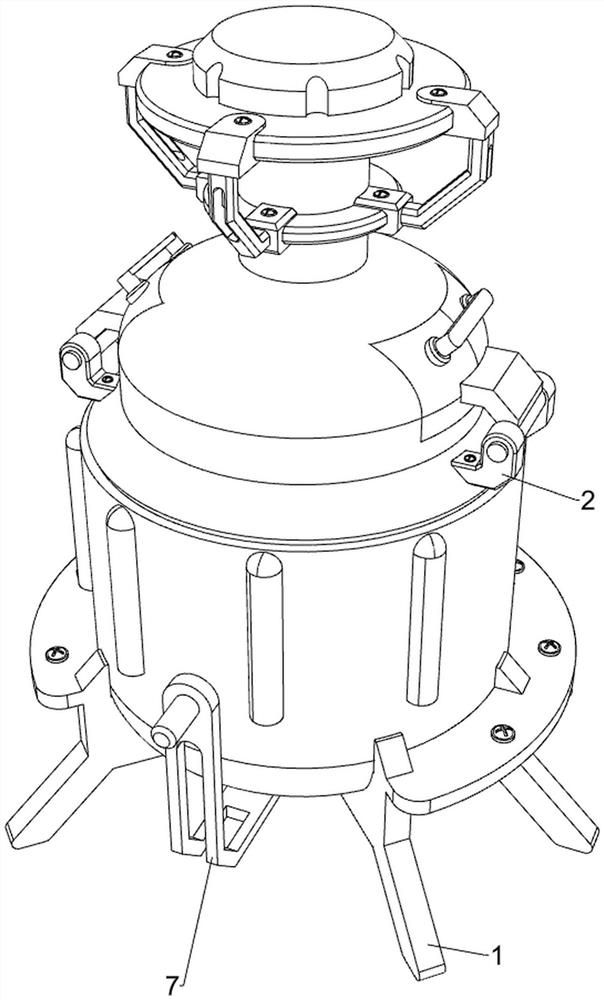

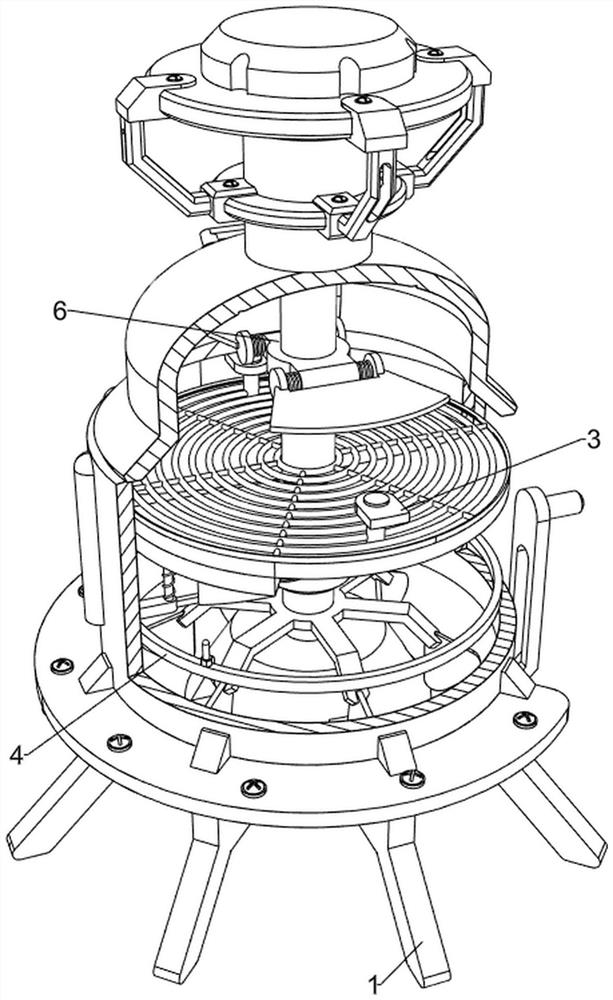

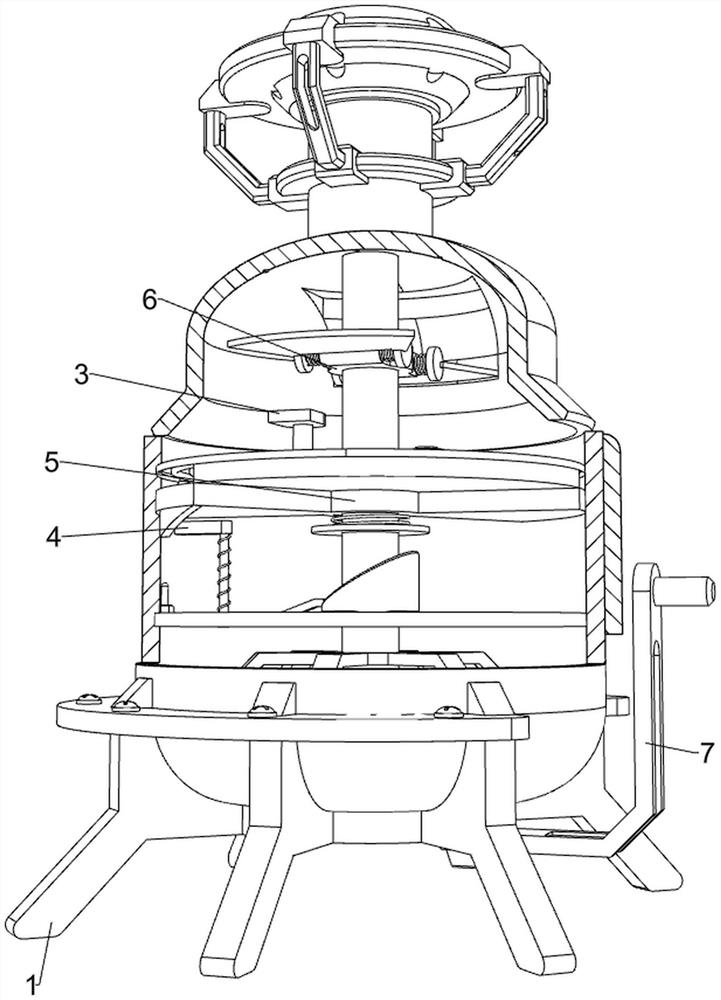

[0036] A compound oil-phase reactor stirring device, such as Figure 1-7 As shown, it includes a support base 1, a material cylinder 11, a fixing frame 12, a motor 13, a first rotating rod 14, a stirring paddle 15, an opening and closing mechanism 2 and a heating mechanism 3. The upper side of the support base 1 is connected with a material cylinder through bolts. 11. The material barrel 11 can be used to place the composite oil phase. The upper left and right sides of the material barrel 11 are provided with feeding ports. The upper side of the material barrel 11 is connected with a fixing frame 12 by bolts. The fixing frame 12 is installed with a motor 13 by bolts. , the output shaft of the motor 13 is provided with a first rotating rod 14, the first rotating rod 14 is rotatably connected with the material cylinder 11, the rotation of the output shaft of the motor 13 can drive the first rotating rod 14 to rotate, and the lower part of the first rotating rod 14 is provided wit...

Embodiment 2

[0041] On the basis of Example 1, as figure 2 , image 3 , Figure 8 and Figure 9 As shown, it also includes an inner wall scraping mechanism 4 capable of scraping off the composite oil phase liquid attached to the inner wall of the material cylinder 11. The inner wall scraping mechanism 4 includes a third fixing block 40, a guide rod 41, a connecting block 42, a spring 43. The scraper 44, the contact rod 45 and the rotating block 46, a third fixing block 40 is arranged on the inner wall of the front side of the material cylinder 11, a guide rod 41 is arranged on the lower side of the third fixing block 40, and the guide rod 41 is slidably connected with a connection Block 42, the guide rod 41 can guide the connecting block 42, a spring 43 is arranged between the upper side of the connecting block 42 and the lower side of the third fixing block 40, the spring 43 is wound on the surface of the guide rod 41, and the spring 43 can make The connecting block 42 moves and reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com