Waste exhibition appliance recovery processing equipment and recovery processing method

A technology of recycling and display tools, applied in grain processing, solid waste removal, etc., can solve problems such as hidden safety hazards, flying fragments, single crushing method, etc., to improve crushing effect, improve torque strength, and avoid breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

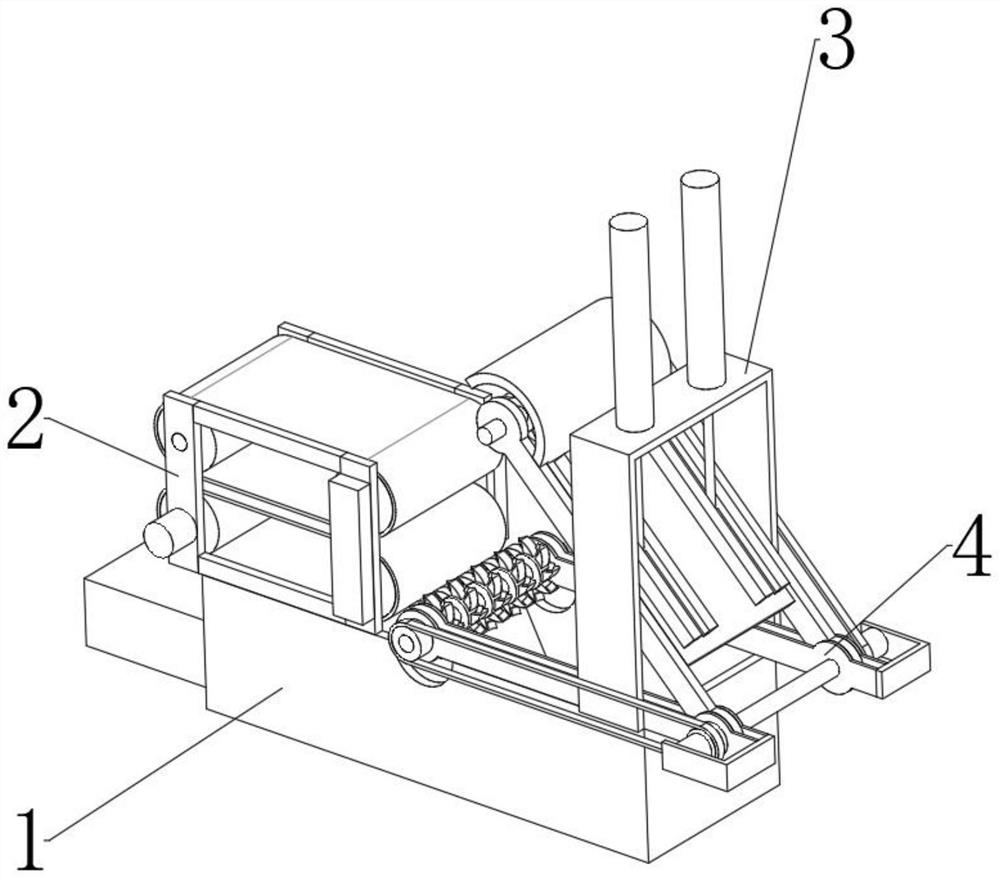

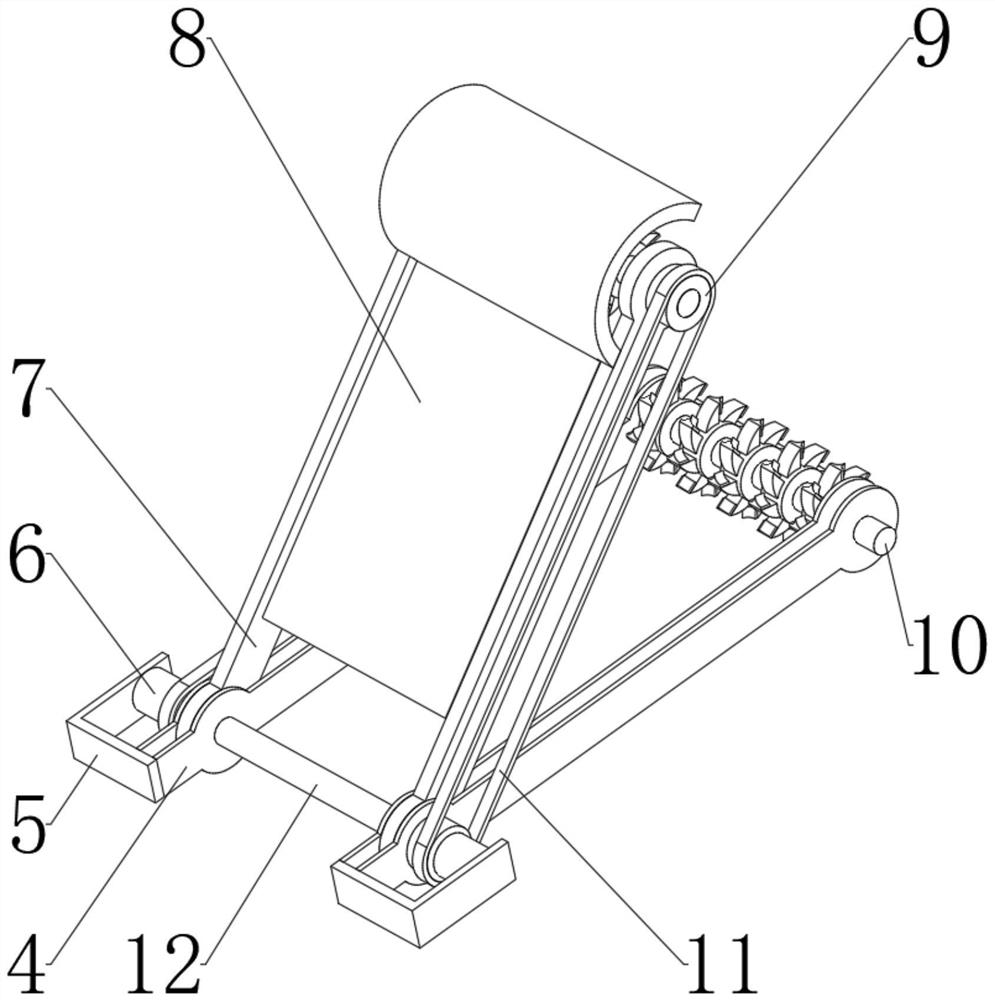

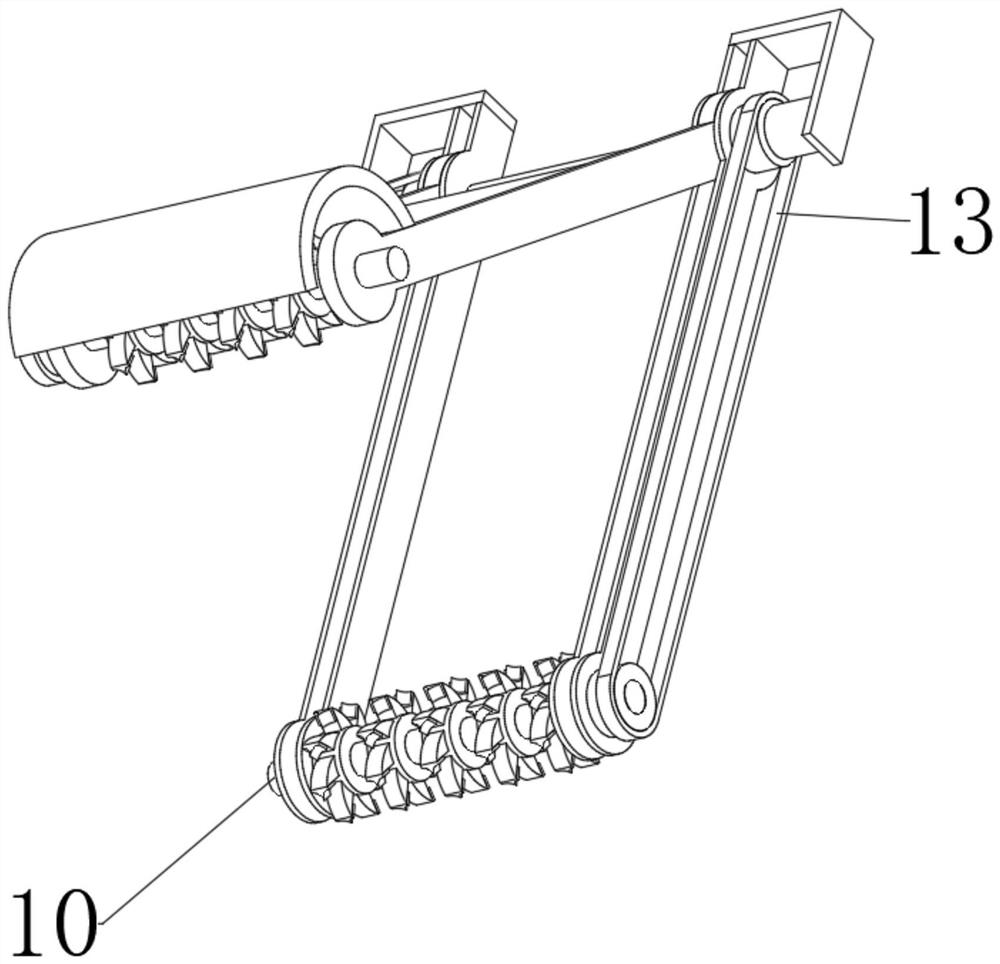

[0031] like Figure 1-Figure 8 As shown, the waste display equipment recycling and processing equipment provided in this embodiment includes a material box 1 and a conveying assembly and a crushing assembly arranged on the top of the material box. The crushing component relies on the jaw structure. While rotating and crushing the plate, it presses the plate to improve the crushing effect, and at the same time directly sends the crushed material to the bottom of the device to avoid the crushed material from collapsing and causing pollution around the device. The crushing components are adjacent to each other. When performing crushing, the subsequent part of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com