Fixed-length shearing device for rod and wire production

A technology of cutting to length, rod and wire, applied in the direction of shearing device, accessory device of shearing machine, shearing machine equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

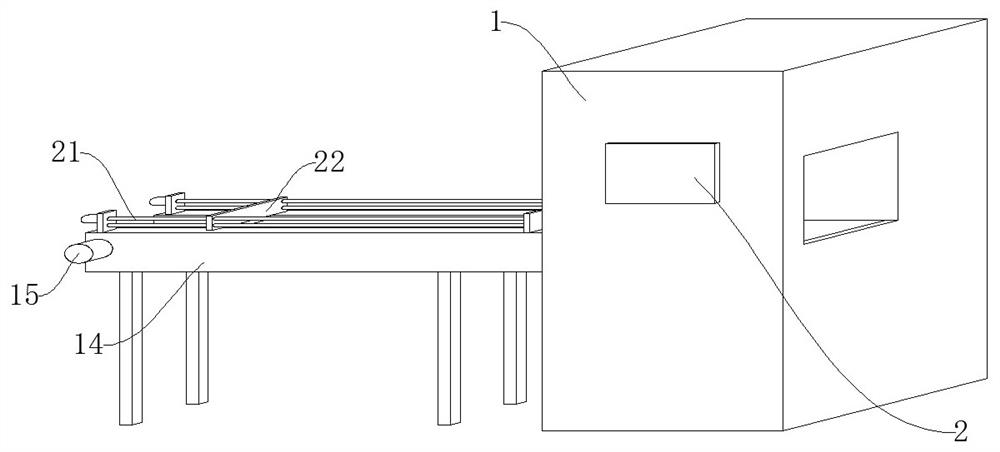

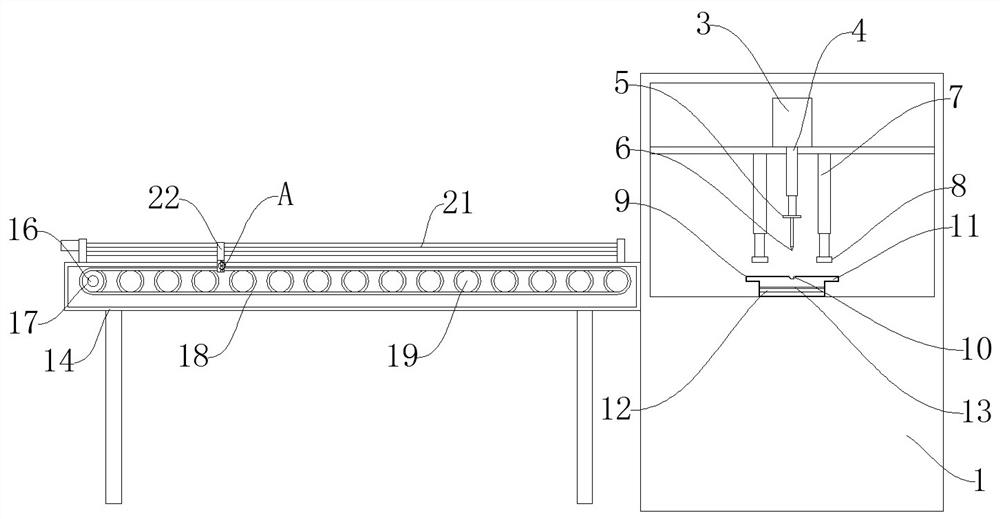

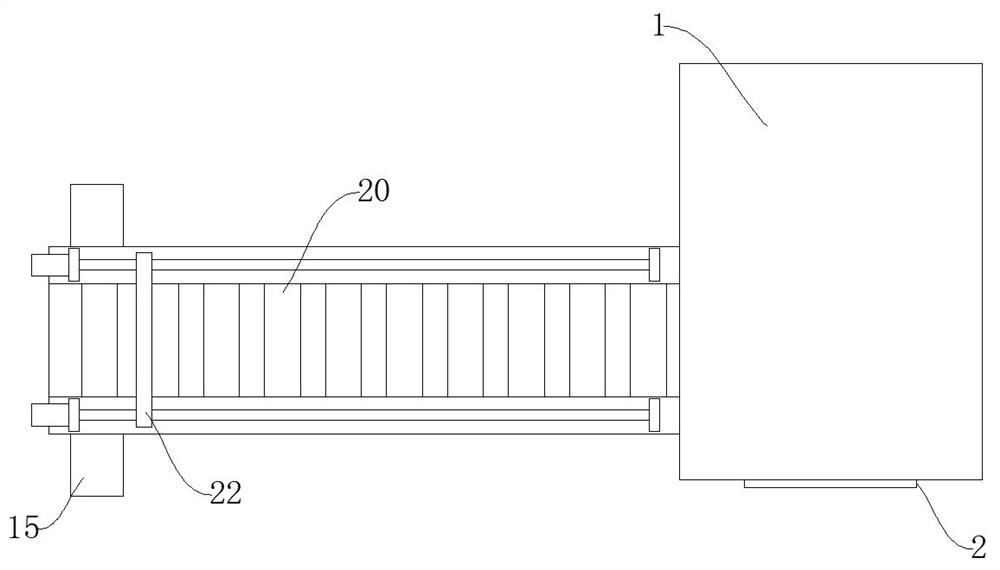

[0016] like Figure 1-Figure 4 As shown, a fixed-length shearing device for bar and wire production includes a body 1, a support frame 14 and an electric sliding rail 21. An operation panel 2 is installed on one side of the body 1, and the staff can use the operation panel 2 to control the device. A hydraulic cylinder 3 is fixed on the upper part of the body 1. The hydraulic cylinder 3 can drive a piston rod 4 to move. A piston rod 4 is installed at the bottom of the hydraulic cylinder 3. The piston rod 4 can drive the mounting plate 5 to move. The bottom of the piston rod 4 is fixed with a mounting plate. 5. The mounting plate 5 can be installed with a cutting knife 6, and the bottom of the mounting plate 5 is connected with a cutting knife 6. The cutting knife 6 can cut the rod and wire, and both sides of the cutting knife 6 are provided with electric push rods 7, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com