Rapid turnover device for end socket

A flipping device and head technology, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of head deformation, head crush damage, head turning inconvenient, etc., to reduce head deformation The effect of uniform weight and force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, but do not limit the rights thereof.

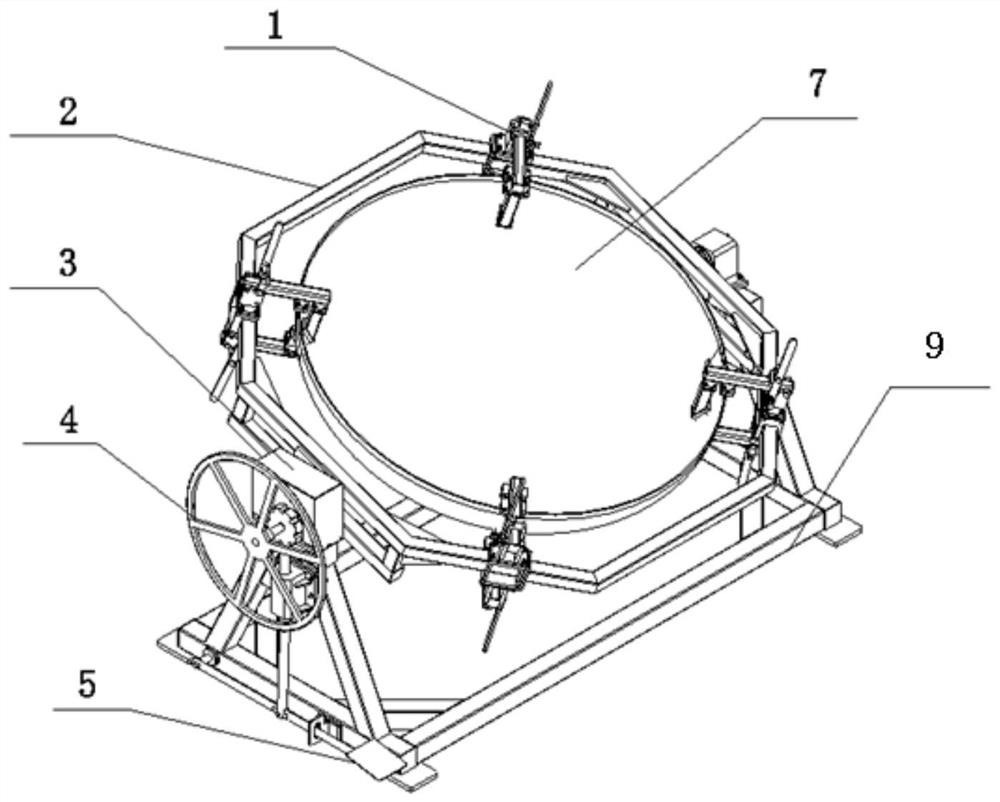

[0018] refer to Figure 1-Figure 2 , a head flipping device, comprising a base and a head flipping frame; the head flipping frame is rotatably mounted on the base, and a number of heads are installed on the head flipping frame along the circumferential direction of the head to clamp and fix the head The clamping mechanism is installed between the head turning frame and the base to make the head turn over;

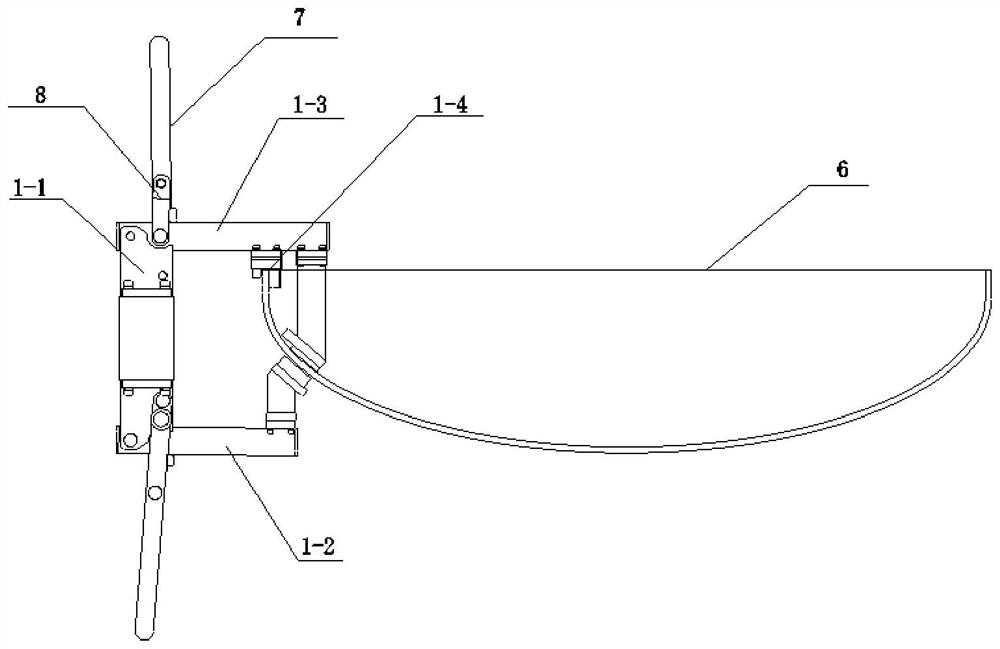

[0019] The clamping mechanism includes a mounting seat installed on the head turning frame, an upper locking arm and a lower locking arm capable of clamping the head are installed on the mounting seat, and the upper locking arm is downwardly provided with an upper locking arm and a lower locking arm. A limit slot matched with the end of the head and an upper lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com