Machining tool and machining method for shell and inner bottom of injector

A processing method and injector technology, which are used in manufacturing tools, other manufacturing equipment/tools, etc., to achieve the effects of improving processing accuracy, improving processing qualification rate, and improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

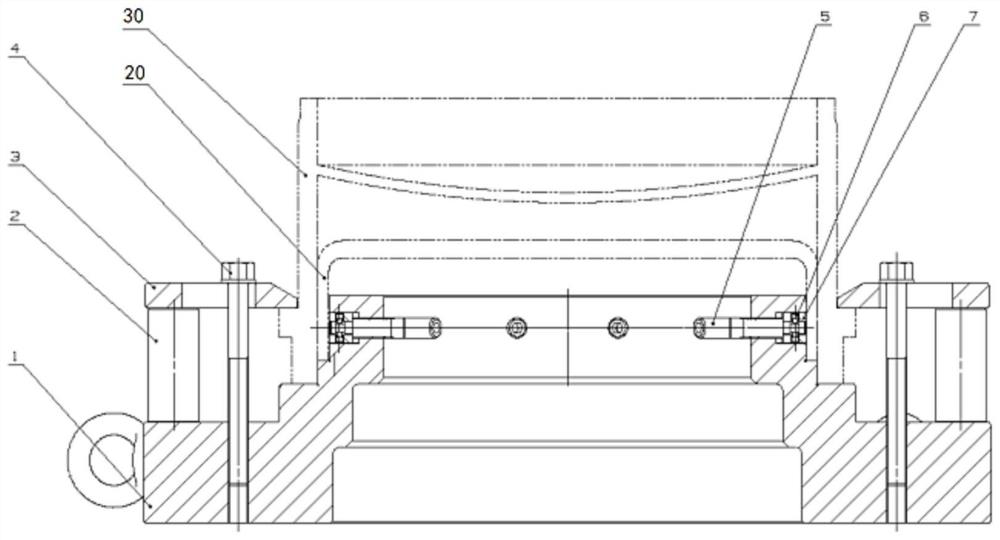

[0029] A processing tool and processing method for an injector housing and an inner bottom, the injector housing 30 and the upper end hole of the inner bottom are welded together when they are coaxial, and the injector housing 30 and the upper end of the inner bottom 20 are welded together. The number of faces is large and the number is the same. This method is to use the same processing procedure to process the upper end faces of the injector housing 30 and the inner bottom 20 respectively when the injector housing 30 and the inner bottom 20 are clamped at one time to ensure the positioning accuracy. The relative positional accuracy of the injector housing 30 and the hole in the inner bottom 20 can be achieved.

[0030] The processing tool includes a positioning plate 1, a spacer 2, a pressure plate 3, a first screw 4, a second screw 5, a cylindrical end set screw 6, and an expansion ring 7. The processing tool realizes the connection between the injector housing 30 and the in...

Embodiment 2

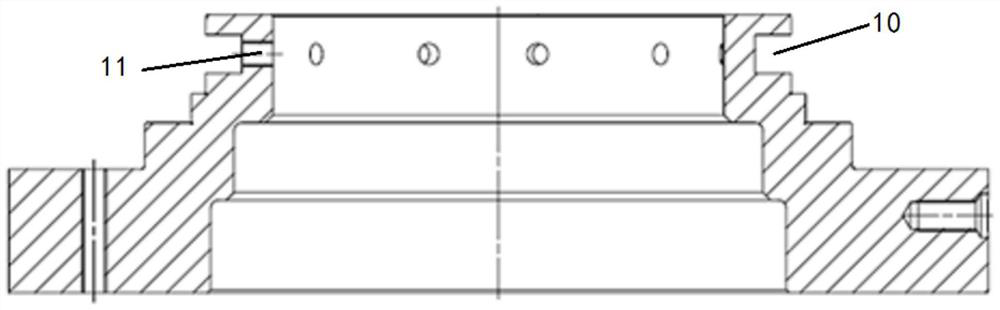

[0045] A processing tool for an injector housing and an inner bottom, comprising a positioning plate 1, a spacer 2, a pressure plate 3, and a plurality of ring-shaped expansion rings 7;

[0046] The positioning plate 1 is cylindrical as a whole, the outer surface is stepped, and the outer envelope gradually shrinks from one end to the other end. An annular groove 10 is provided on the smallest end, and a hole 11 is arranged in the groove 10. The interior of the positioning plate 1 A through hole is formed along the axial direction; the inner bottom 20 is sleeved on the smallest end of the positioning plate, and the injector housing 30 is sleeved on the positioning plate and the inner bottom 20 at the same time;

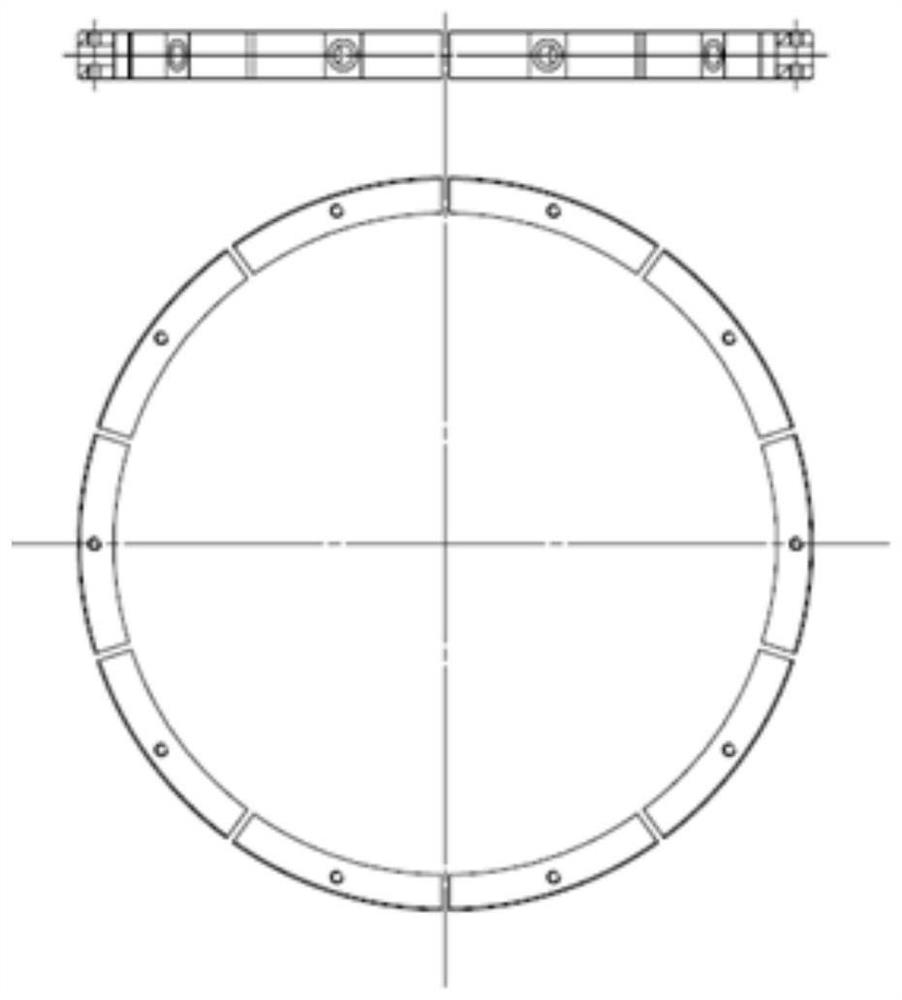

[0047] A plurality of expansion rings 7 are located in the groove 10 and abut against the inner circle of the inner bottom 20. By adjusting the position of one or more expansion rings 7, the outer circle of the inner bottom 20 can reach a predetermined position;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com