Full-biodegradable environment-friendly tableware mold pressing device and preparation method thereof

An all-biological and tableware technology, applied to household appliances, other household appliances, household components, etc., can solve the problems of high temperature, inconvenient operation, gaps in the parting surface, etc., to achieve the effect of simple operation, easy implementation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

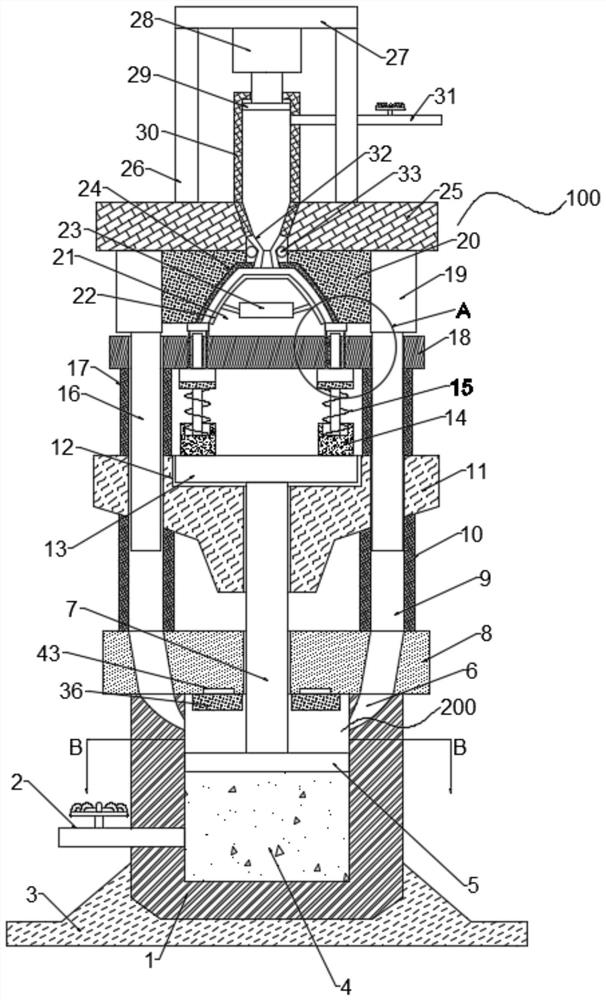

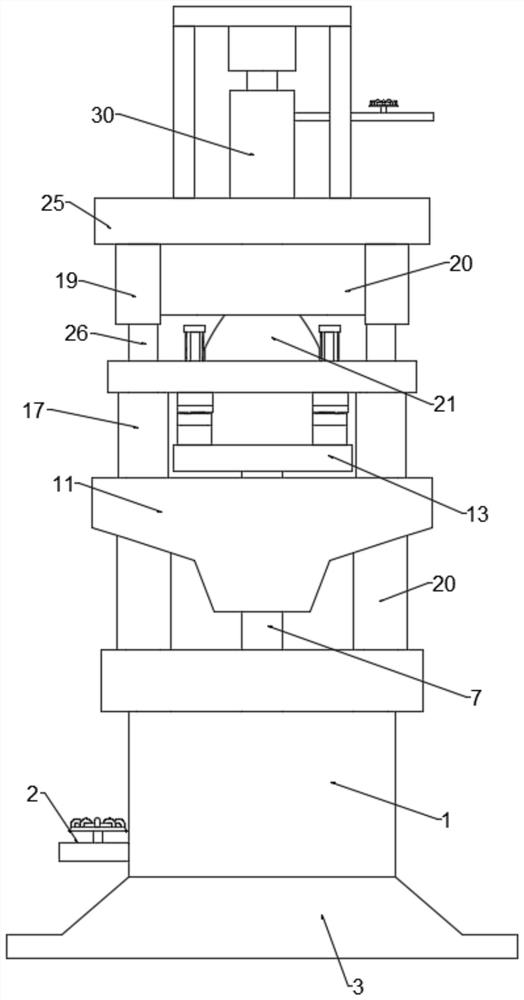

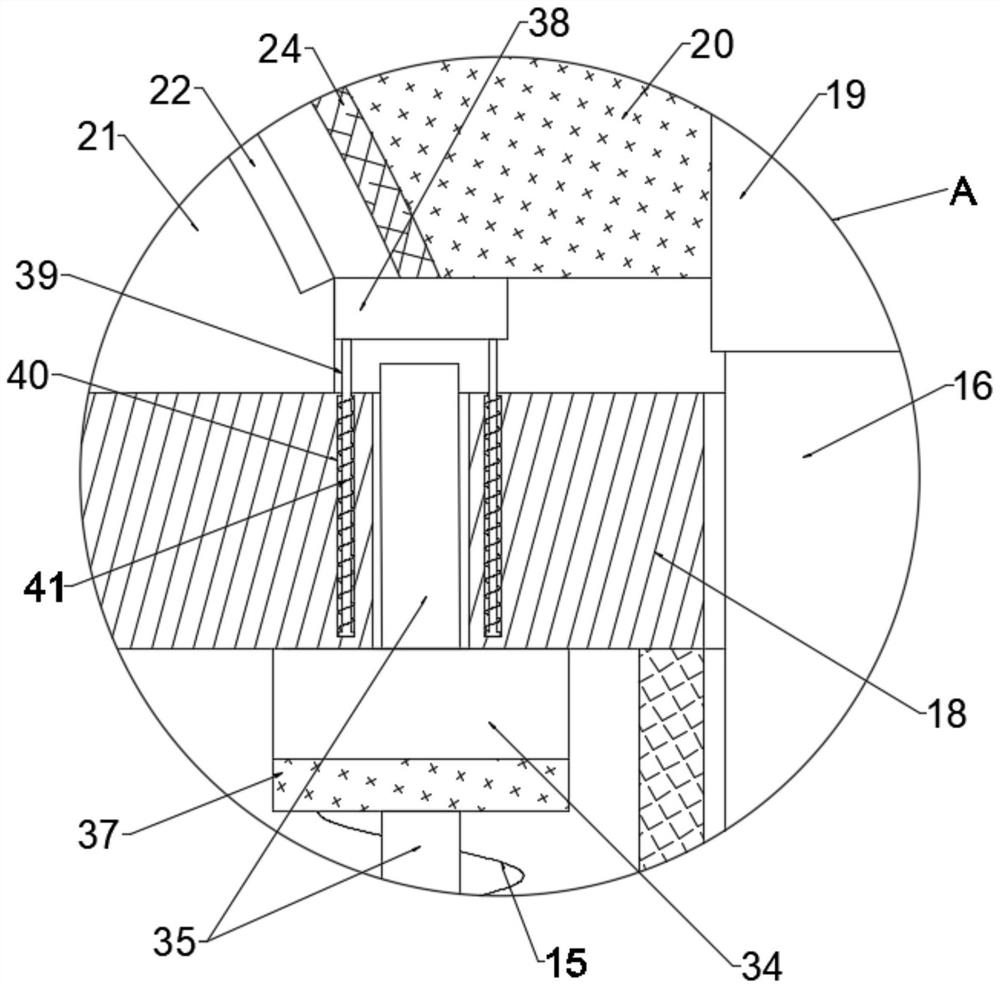

[0029] see Figures 1 to 4, In the embodiment of the present invention, the fully biodegradable environmentally friendly tableware molding device includes an oil tank 1, a base 3 is installed on the lower part of the oil tank 1, a hydraulic oil 4 is installed inside the oil tank 1, and the left side wall of the oil tank 1 is installed There is an oil inlet pipe 2, and the oil inlet pipe 2 extends to the interior of the oil tank 1, the upper surface of the oil tank 1 is fixed with a bearing plate 8, the top of the bearing plate 8 is fixed with a connecting plate 11, and the upper surface of the connecting plate 11 is fixedly connected There is a second connecting rod 17, the upper surface of the second connecting rod 17 is fixed with a dividing plate 18, the interior of the dividing plate 18, the second connecting rod 17, the connecting plate 11, the first connecting rod 10 and the bearing plate 8 pass through A sliding tube 9 is provided, and a sliding rod 16 is slidably conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap