Filling auxiliary device for infusion bag production line

An auxiliary device and production line technology, applied in the direction of transportation packaging, transportation and packaging, packaging, etc., can solve the problems of inconvenient disassembly and installation, large volume, waste of manpower, etc., and achieve the effect of easy disassembly and installation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

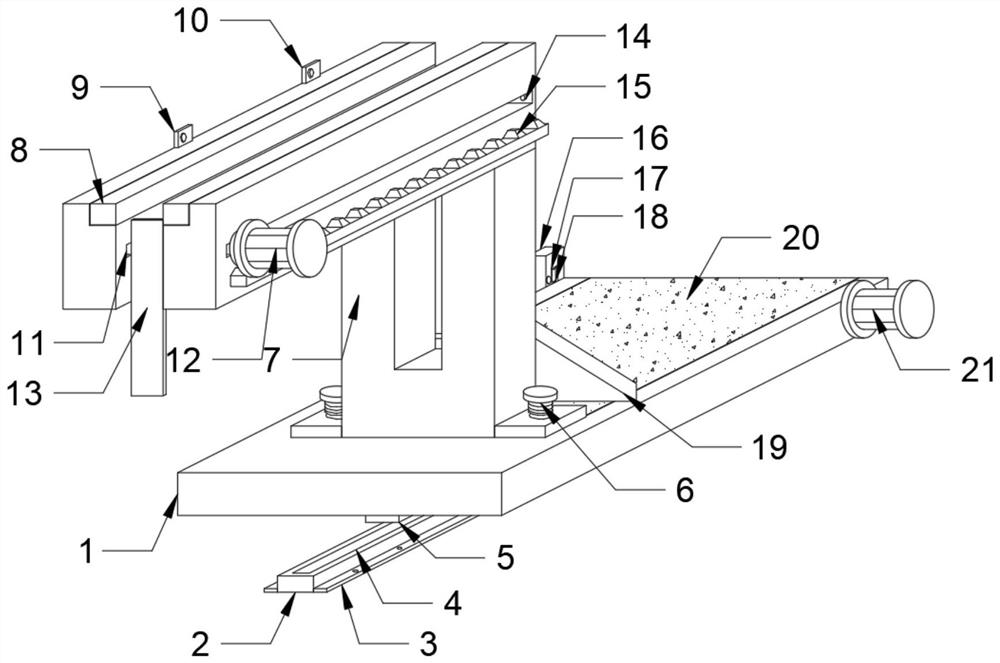

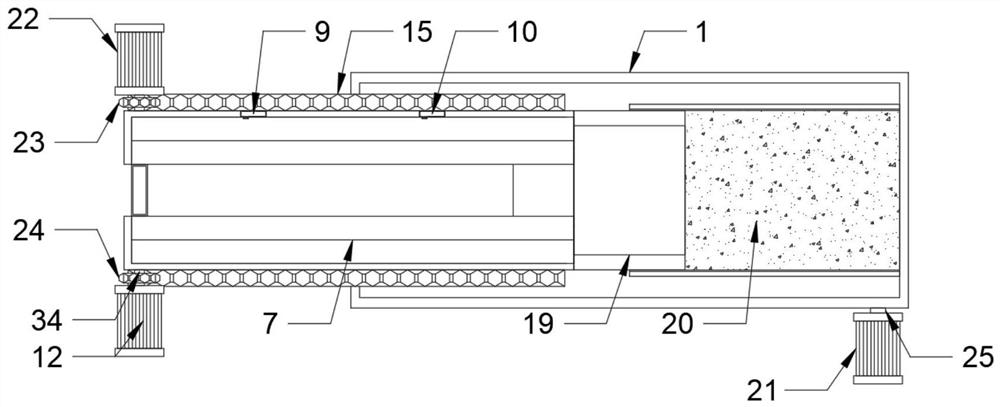

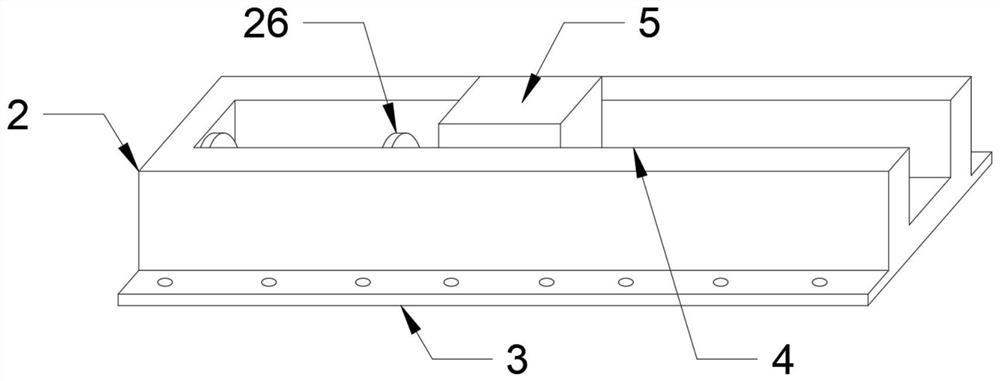

[0028] like Figure 1-Figure 6 As shown, this embodiment provides a filling auxiliary device for an infusion bag production line, including a limit operation table 1, a sliding block 5, a positioning screw 6, an operation frame 7, a weight sensor 8, a filling infrared scanning Part 9, cover infrared scanning part 10, moving rack 15, display panel 16, limit slot 17, first electric telescopic rod 18, guide plate 19 and shock pad 28, limit the side of the top middle of the operating table 1 An operation frame 7 is installed, the positioning screws 6 penetrate through the bottom two sides of the operation frame 7 and are connected to the limit operation table 1. The we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com