Multifunctional paper packaging box bundling system

A packaging box, multi-functional technology, applied in packaging, bundling materials, packaging protection and other directions, can solve the problem of labor costs and other problems, and achieve the effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

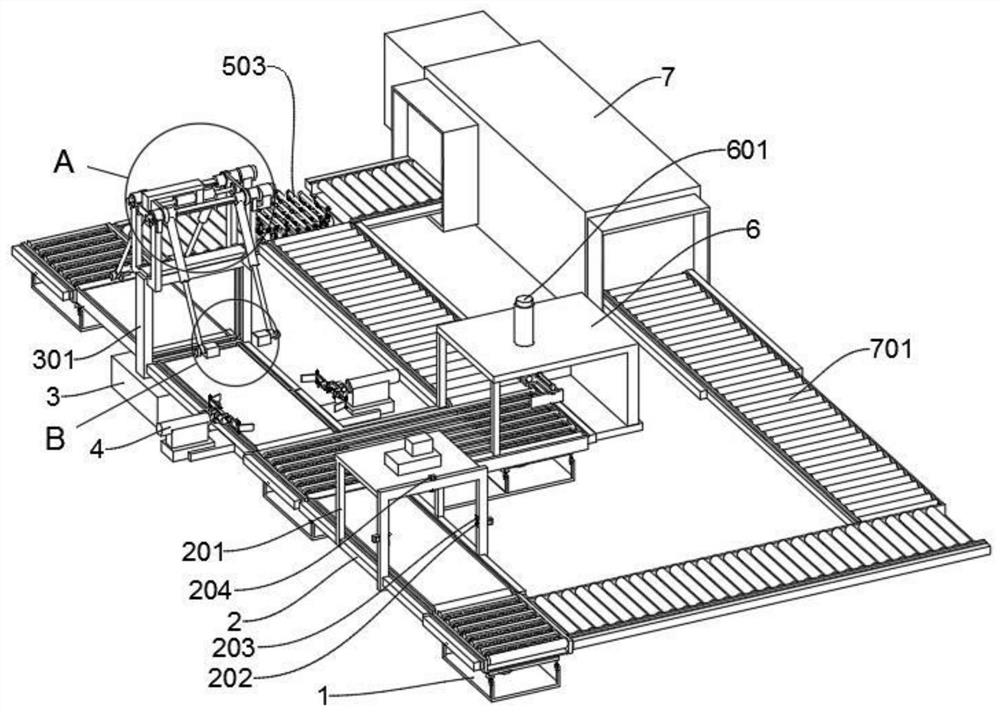

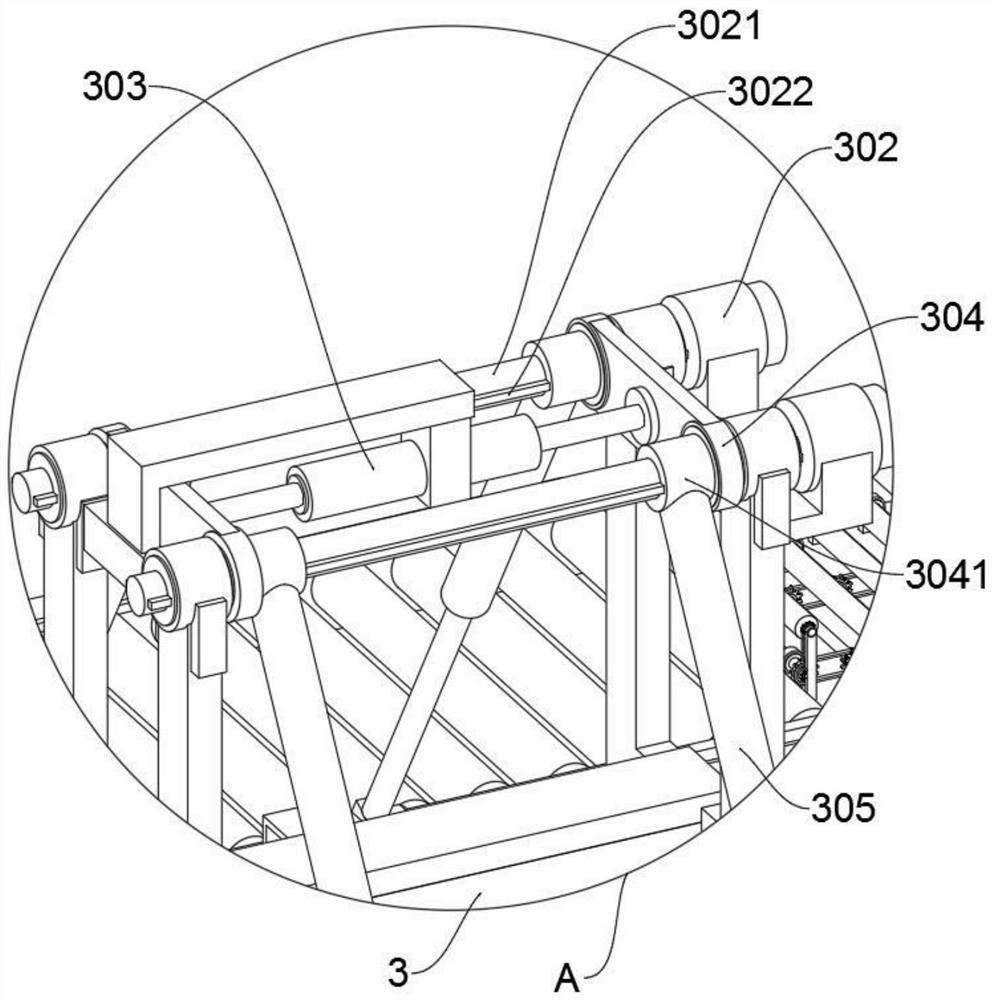

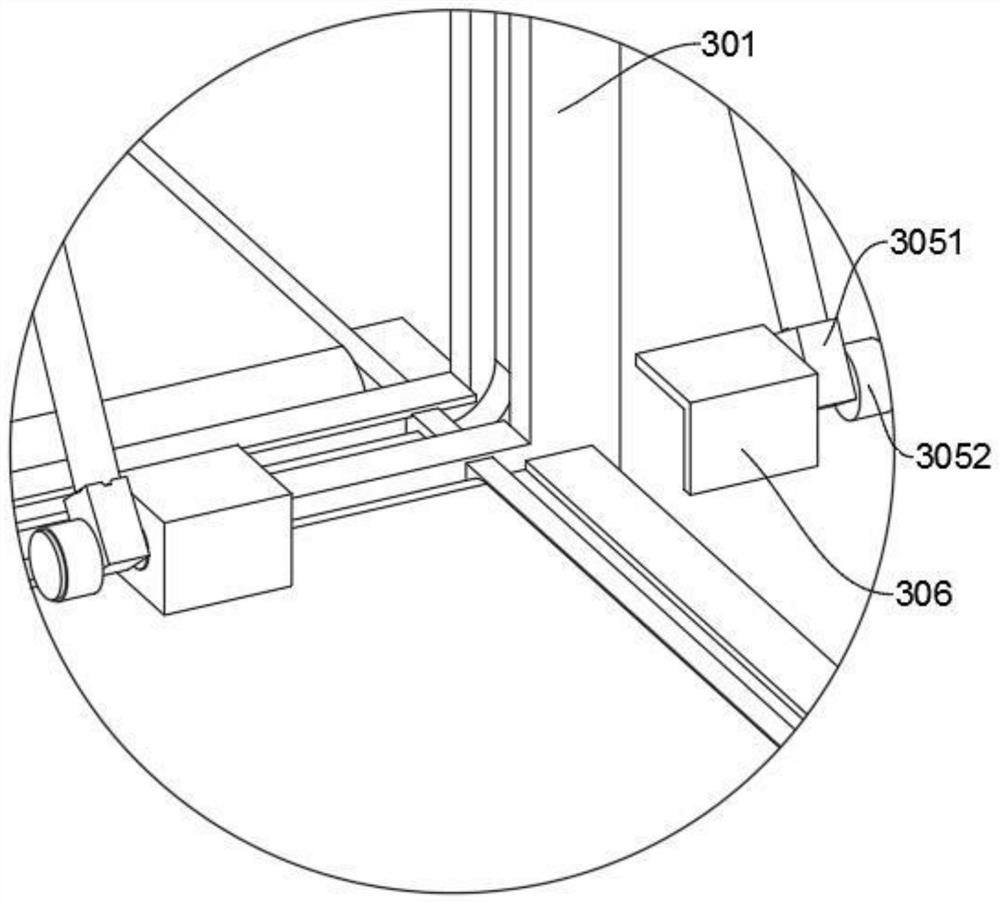

[0050] Example 1: Please refer to Figure 1 to Figure 10 :

[0051] The present invention proposes a multi-functional paper packaging box bundling system, including: a box body detection mechanism, a belt positioning mechanism, a tour code printing mechanism and a corner conveyor belt 1, the box body detection mechanism is arranged on the rear side of the corner conveyor belt 1, and the number of corner conveyor belts 1 It is arranged in three groups, the belt positioning mechanism is arranged on the rear side of the box body detection mechanism, and the circuit printing mechanism is arranged on the right side of the belt positioning mechanism; the corner conveyor belt 1 includes a bottom plate 101 and a carriage 102; the rear side of the corner conveyor belt 1 is connected with In the feeding conveyor belt 2, the box detection mechanism is connected and arranged on the top of the feeding conveyor belt 2; the rear side of the feeding conveyor belt 2 is connected with a belting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com