Spicy hotpot condiment boxing process

A hot pot bottom material and spicy technology, which is applied in packaging, liquid materials, transportation and packaging, etc., can solve the problems of low packing efficiency of spicy hot pot bottom material, sore arms of operators, cumbersome operation process, etc., so as to improve efficiency and avoid Sore arms and the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, the rotary charging system used in this embodiment will be described.

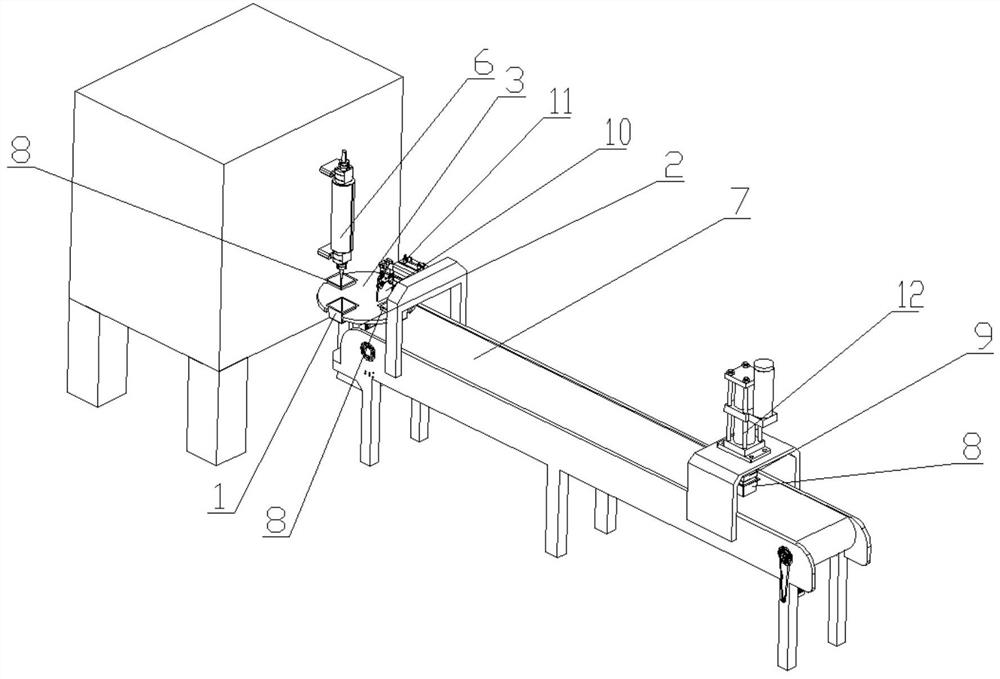

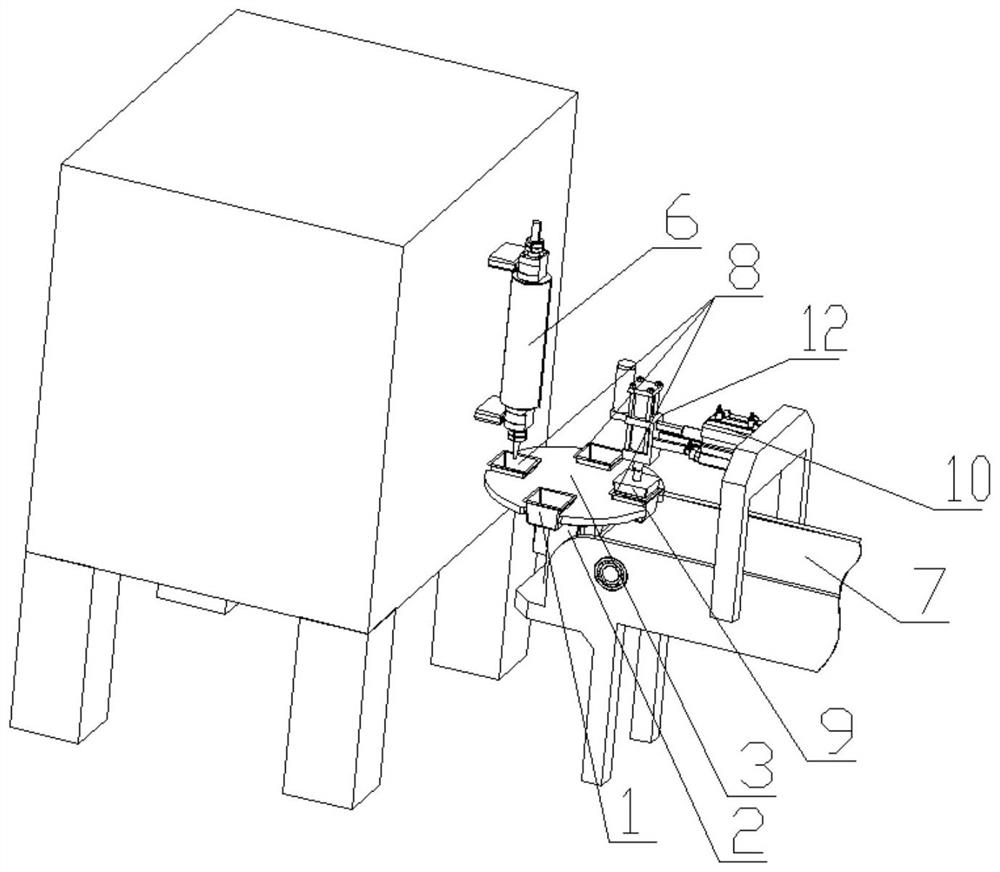

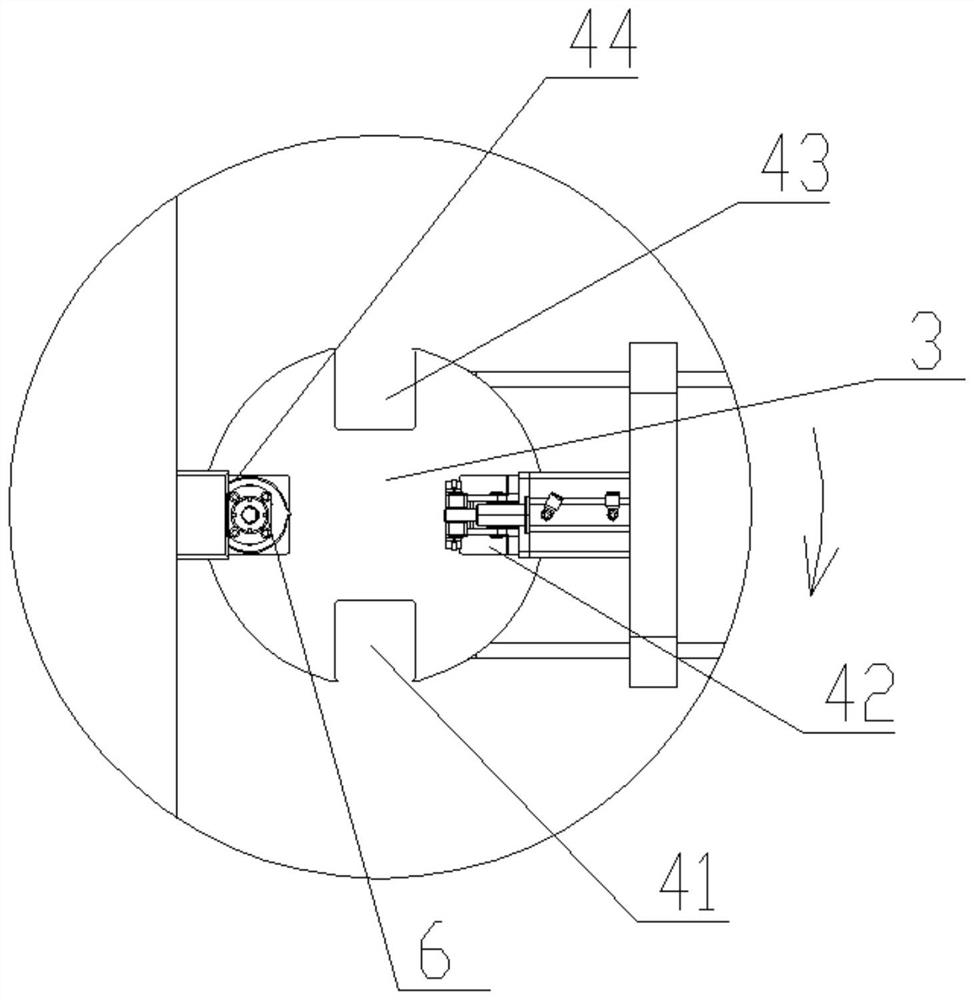

[0033] like figure 1 , image 3 As shown, the rotary charging system includes a disc 3 connected to the output end of the motor 2, and four evenly arranged rectangular notches (located at 0° (360°) positions on the circumference respectively) are arranged on the disc 3 along the circumferential direction. The first rectangular notch 41, the second rectangular notch 42 at the 90° position, the third rectangular notch 43 at the 180° position, the fourth rectangular notch 44 at the 270° position, the rectangular notch is used for the card loading box 1, the disc 3. A filling gun 6 with a filling device is arranged above the edge (the filling device is in the prior art and will not be described again), and a conveyor belt 7 is provided on the opposite side of the filling gun 6. The top of the left end of the conveyor belt 7 is provided. The surface is located below the edge of the disc 3; durin...

Embodiment 2

[0048] The rotary charging system used in this example is as figure 2 , image 3 As shown, it includes a disc 3 connected to the output end of the motor 2. The disc 3 is provided with four evenly arranged rectangular notches along the circumferential direction, which are respectively located at the 0° (360°) position, 90° position, 180° position on the circumference. Position, 270° position, the rectangular gap is used for the card loading box 1, the filling gun 6 of the filling equipment is arranged above the edge of the disc 3, and the conveyor belt 7 is arranged on the opposite side of the filling gun 6 to convey the material. The top surface of the left end of the belt 7 is located below the edge of the disc 3; during the rotation of the disc 3, all the rectangular gaps can be located directly below the filling gun 6 and directly above the left end of the conveyor belt 7.

[0049] The cone 13 is arranged above the end of the conveyor belt 7, the cone 13 is vertically arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com