Packaging equipment for bagged herb tea production

A packaging equipment, herbal tea technology, applied in packaging sealing/fastening, packaging, packaging food, etc., can solve the problem that it is difficult to meet the clamping and transfer of bagged herbal tea cartons, and achieve convenient access to small cartons and convenient processing efficiency , Improve the effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

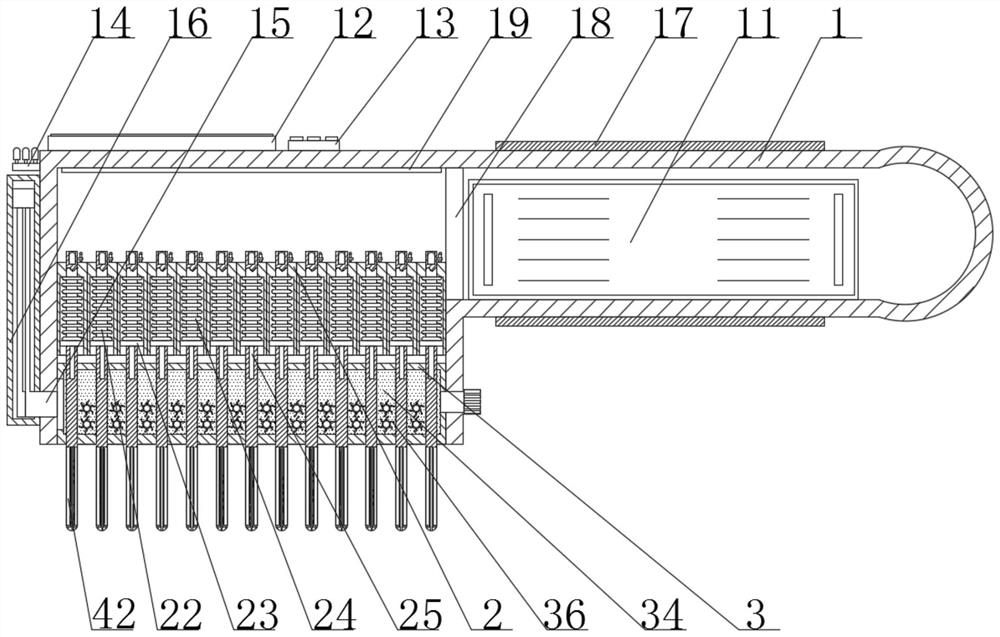

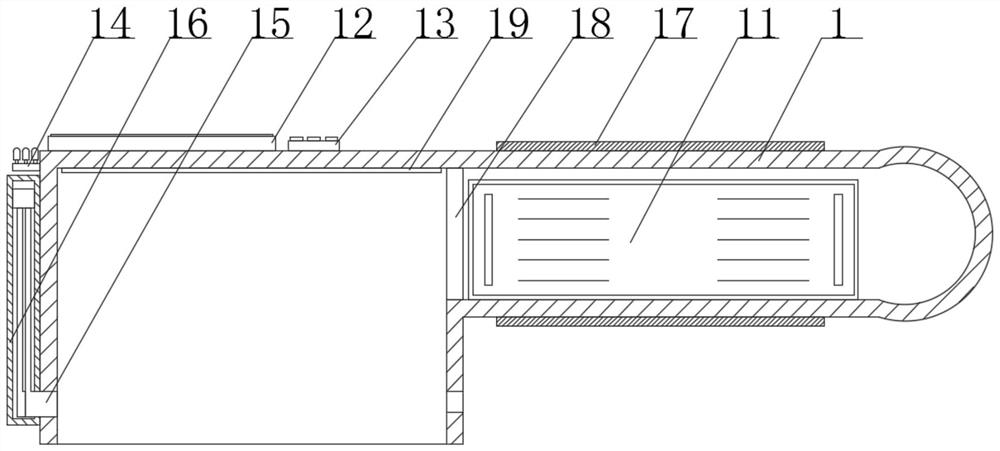

[0027] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a packaging device for the production of bagged herbal tea includes: an installation box 1, a drive frame 2 and a storage box 3; 1. One end of the upper surface of the inner wall is fixedly connected to the limiting plate 19 by bolts. The heating device further includes: a casing 16. The heating device is specifically an electric heating plate 15. One side of the casing 16 is fixedly connected with the installation box 1 by bolts, and a plurality of ventilation holes are opened on the lower surface of the casing 16 .

[0028] Among them, the heating device can effectively heat and melt the colloid 34, so as to prevent the colloid from solidifying in a low temperature environment and affect the packaging operation, and the limit plate 19 can effectively limit the driving range of the drive frame 2. At the same time, it also has the effect of protecting the upper surface of the inner...

Embodiment 2

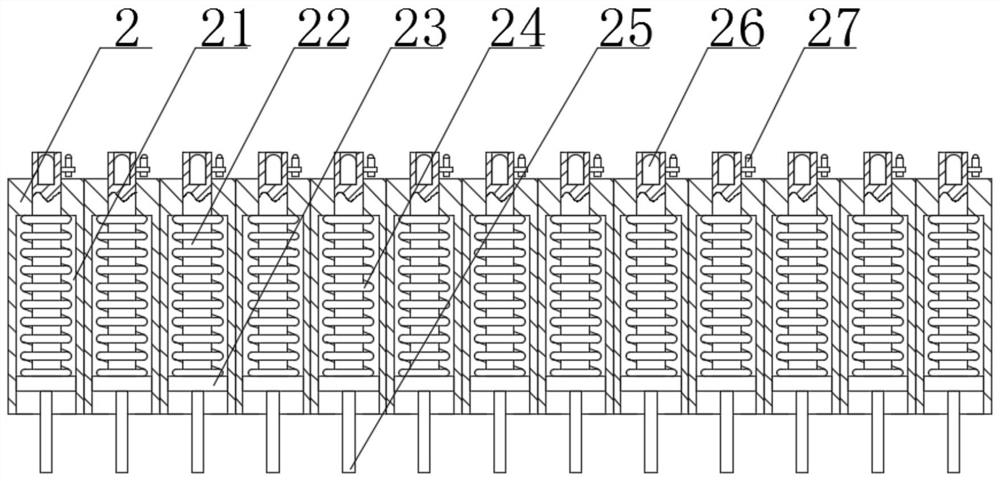

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a packaging device for the production of bagged herbal tea includes: an installation box 1, a drive frame 2 and a storage box 3; 1. One end of the upper surface of the inner wall is fixedly connected to the limiting plate 19 by bolts, and one side of the inner wall of the installation box 1 near the bottom end is connected with a plurality of drive frames 2 by bolts, and any two adjacent drive frames 2 are fixed by bolts Connecting, the middle part of the lower surface of the plurality of driving frames 2 is provided with an accommodating groove 21, and the middle part of the upper surface of the plurality of driving frames 2 is movably inserted with a guide rod 22, and the bottom end of the guide rod 22 penetrates the accommodating groove 21 and is fixed by bolts A backing plate 23 is connected, an elastic reset member 24 is arranged on the periphery of the guide rod 22 between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com