Polymerizable composition, aqueous acryl resin and preparation method thereof

A technology of polymerizable composition and acrylic resin, applied in the field of water-based acrylic resin, water-based acrylic resin and its preparation, can solve the problems of low solvent resistance of acetone, poor solvent resistance and need to be improved, etc. The effect of meeting physical requirements and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

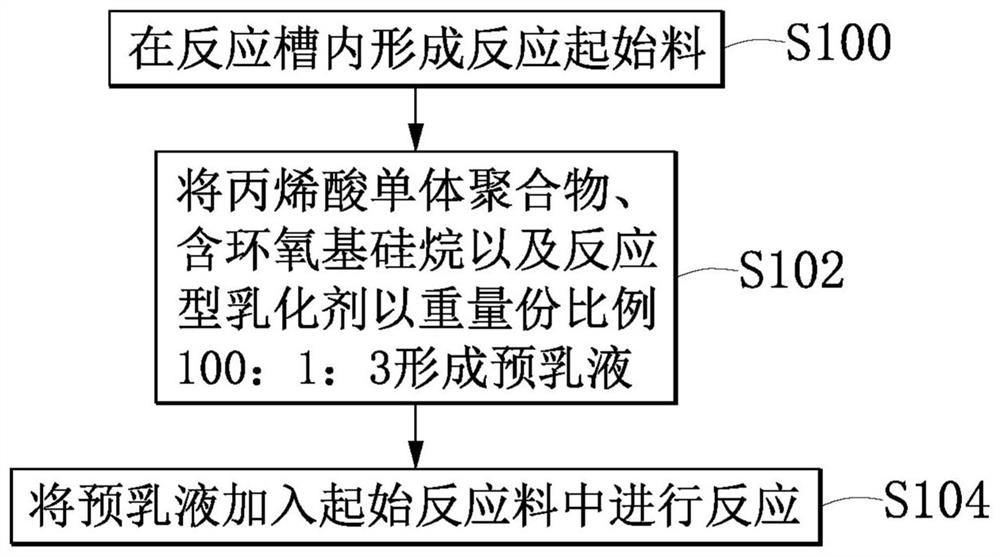

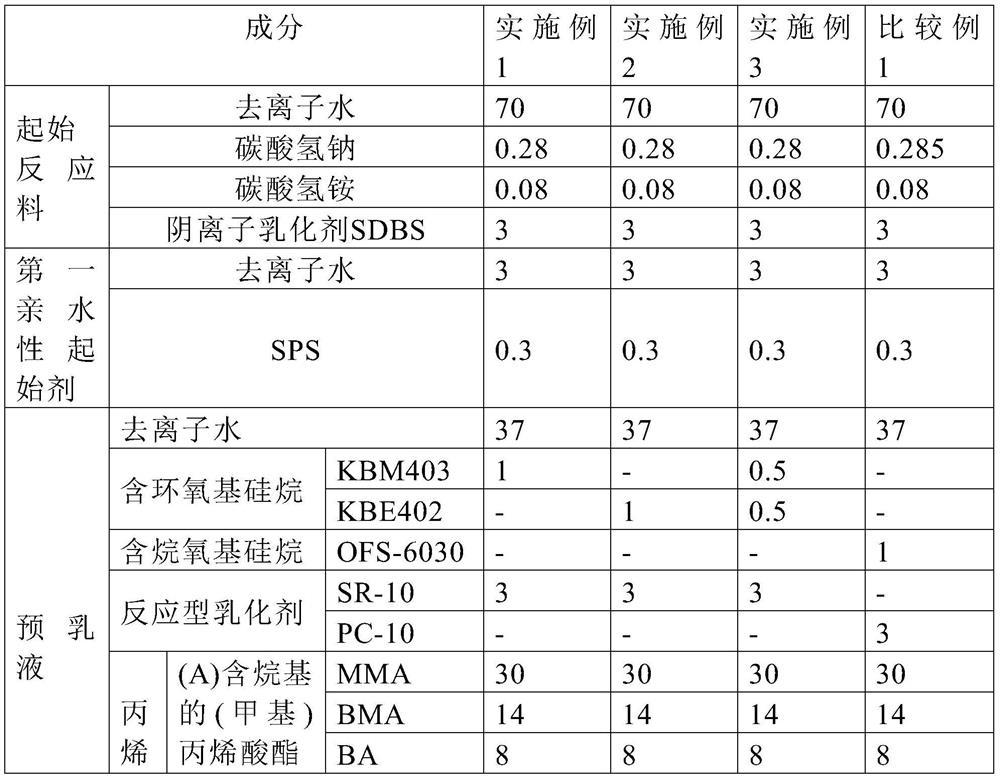

[0050] The ingredients of each example are shown in Table 1, and the starting reactants were added to the reaction tank and mixed uniformly. After raising the temperature in the reaction tank to 75°C, the first hydrophilic initiator was added, and stirring was continued for 10 minutes. Using a mixer, 37 parts by weight of deionized water, 3 parts by weight of reactive emulsifier SR-10, epoxy-containing silane and acrylic monomer polymer were uniformly mixed to form a pre-emulsion. Maintain the temperature at 75°C and add the pre-emulsion into the reaction tank in the form of droplets. After 30 minutes of reaction, add the aqueous solution formed by the second hydrophilic initiator into the reaction tank in the form of droplets, and the dropwise addition time is controlled at Within 4 hours, then the temperature was raised to 80°C for 2 hours, and after the reaction, the temperature in the reaction tank was lowered to below 40°C, and then the pH value of the obtained product wa...

Embodiment 2

[0052] The reaction scheme of Example 2 is the same as that of Example 1, except that the polymerizable composition contains 1 part by weight of 3-glycidoxypropyl)methyldiethoxysilane (KBE402). After the reaction, the solid content was calculated to be 43% (by weight), and a film was prepared and its physical properties were measured. The results are shown in Table 2.

Embodiment 3

[0054] The reaction scheme of Example 3 is the same as that of Example 1, except that the polymerizable composition contains 0.5 parts by weight of 3-glycidoxypropyl)trimethoxysilane and 0.5 parts by weight of (3-glycidoxypropyl)trimethoxysilane propyl) methyldiethoxysilane. After the reaction, the solid content was calculated to be 43% (by weight), and a film was prepared and its physical properties were measured. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com