Automobile paint cover glaze and preparation method thereof

A technology of automotive paint and top glaze, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problem of damaging the automotive paint surface, and achieve good cleaning effect and strong cleaning and decontamination capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

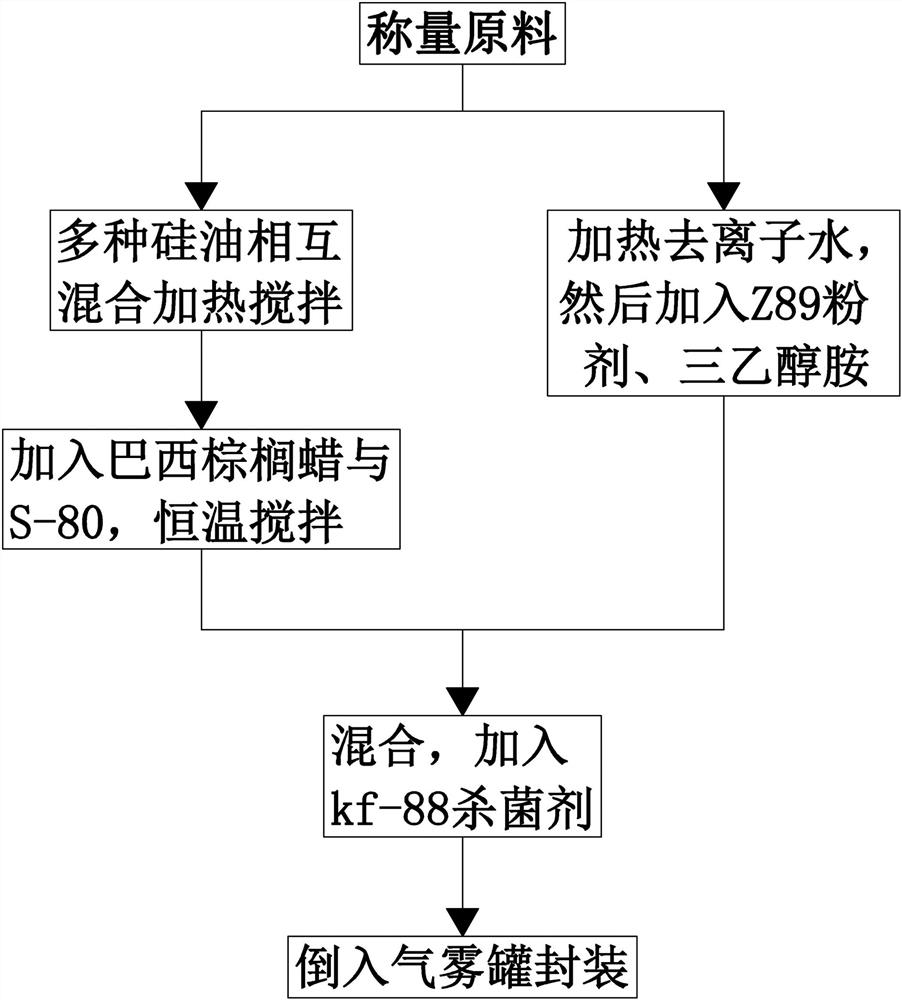

[0021] see attached figure 1 As shown, an automobile paint surface glaze and a preparation method thereof include the following parts: 4 parts of carnauba wax; 8 parts of DC silicone oil; 7 parts of D80; 10 parts of D40; 2 parts of S-80; 7 parts of Z89 powder; 55 parts of ionized water; 0.5 part of triethanolamine; 0.02 part of kf-88 bactericide; wherein, D80 is D80 solvent oil, D40 is D40 solvent oil, and S-80 is S-80 emulsifier.

[0022] In this embodiment, the DC silicone oil includes the following parts: 4 parts of DC-350 silicone oil; 3 parts of DC-1000 silicone oil; 0.5 part of DC-12500 silicone oil; 0.5 part of DC-345 silicone oil.

[0023] The preparation method of the automobile paint finish glaze of the present embodiment comprises the following steps:

[0024] S1. Weigh carnauba wax, DC-350 silicone oil, DC-1000 silicone oil, DC-12500 silicone oil, DC-345 silicone oil, D80, D40, S-80, Z89 powder, deionized water, triethanolamine, kf-88 bactericide, then D80, D40, ...

Embodiment 2

[0033] see attached figure 1 As shown, a kind of automobile paint surface glaze and preparation method thereof, comprising the following parts: 5 parts of carnauba wax; 12 parts of DC silicone oil; 9 parts of D80; 14 parts of D40; 3 parts of S-80; 9 parts of Z89 powder; 65 parts of ionized water; 1 part of triethanolamine; 0.08 part of kf-88 bactericide; D80 is D80 solvent oil, D40 is D40 solvent oil, and S-80 is S-80 emulsifier.

[0034] In this embodiment, the DC silicone oil includes the following parts: 5 parts of DC-350 silicone oil; 4 parts of DC-1000 silicone oil; 1.5 parts of DC-12500 silicone oil; and 1.5 parts of DC-345 silicone oil.

[0035] The preparation method of the automobile paint finish glaze of the present embodiment comprises the following steps:

[0036] S1. Weigh carnauba wax, DC-350 silicone oil, DC-1000 silicone oil, DC-12500 silicone oil, DC-345 silicone oil, D80, D40, S-80, Z89 powder, deionized water, triethanolamine, kf-88 bactericide, then D80, ...

Embodiment 3

[0045] see attached figure 1 As shown, an automobile paint surface glaze and a preparation method thereof include the following parts: 4.5 parts of carnauba wax; 10 parts of DC silicone oil; 8 parts of D80; 12 parts of D40; 2.5 parts of S-80; 8 parts of Z89 powder; 60 parts of ionized water; 0.75 part of triethanolamine; 0.05 part of kf-88 bactericide; D80 is D80 solvent oil, D40 is D40 solvent oil, and S-80 is S-80 emulsifier.

[0046] In this embodiment, the DC silicone oil includes the following parts: 4.5 parts of DC-350 silicone oil; 3.5 parts of DC-1000 silicone oil; 1.0 part of DC-12500 silicone oil; 1.0 part of DC-345 silicone oil.

[0047] The preparation method of the automobile paint finish glaze of the present embodiment comprises the following steps:

[0048] S1. Weigh carnauba wax, DC-350 silicone oil, DC-1000 silicone oil, DC-12500 silicone oil, DC-345 silicone oil, D80, D40, S-80, Z89 powder, deionized water, triethanolamine, kf-88 bactericide, then D80, D40,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com