Combined flow plating machine for plating small parts

A combined, flow plating machine technology, applied in the direction of electrolysis components, cells, electrolysis process, etc., can solve the problems of slow electroplating speed, doping more impurities, poor fluidity of the plating solution, etc., to speed up electroplating speed and enhance fluidity , the effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

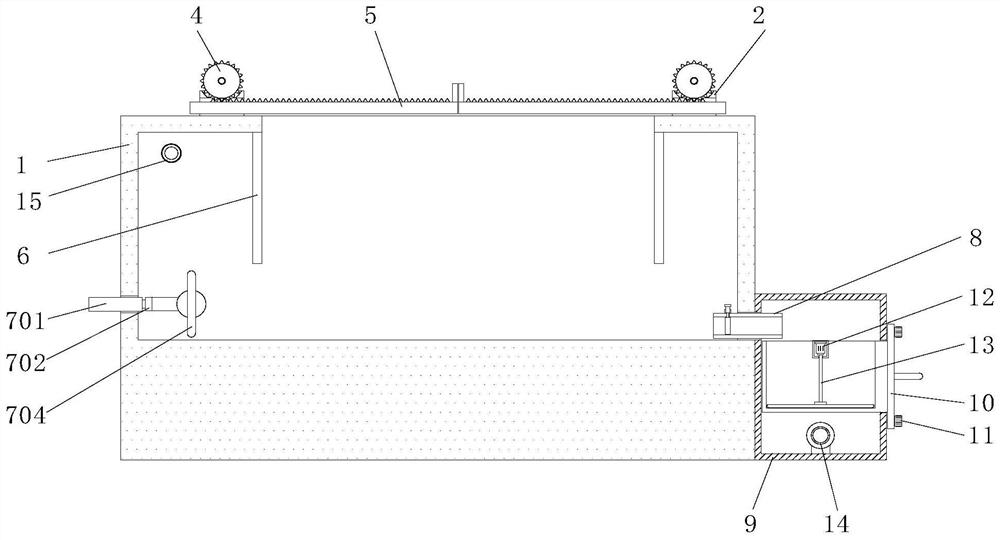

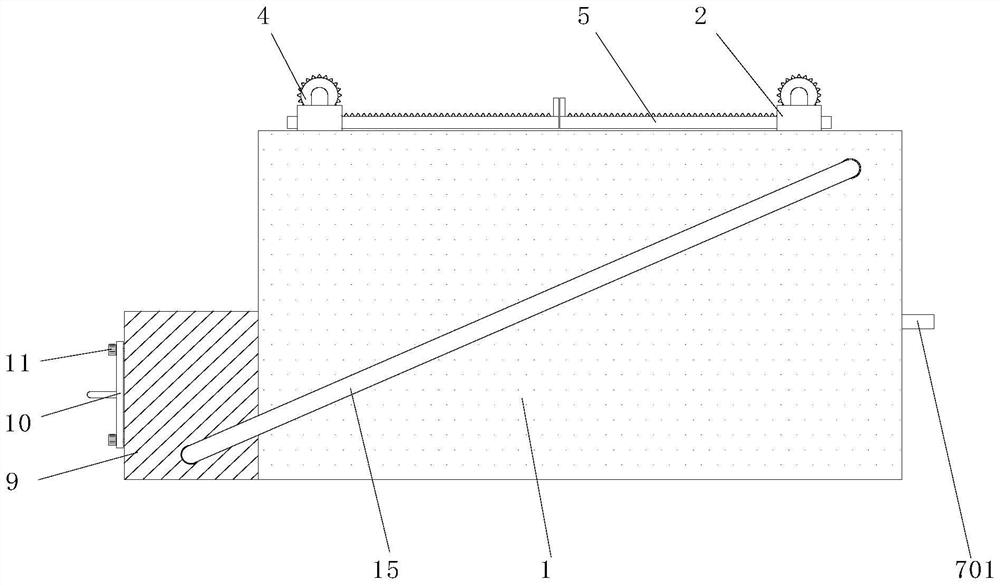

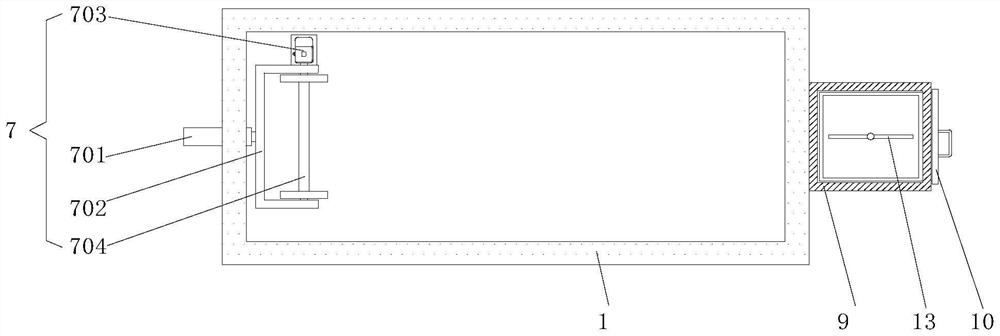

[0023] A preferred embodiment of the combined flow plating machine for plating small parts provided by the present invention is as follows: Figure 1 to Figure 5 As shown, it includes a carrying box 1, a cover plate 5 and a third motor 12. A cover plate 2 is symmetrically fixed on both sides of the top of the carrying box 1, the cover plate 5 penetrates the cover plate 2, and a stopper is symmetrically fixed on both sides of the inner top of the carrying box 1. Plate 6, a push mechanism 7 is fixed on one side of the carrying box 1, an electric liquid outlet valve 8 and a filter box 9 are fixed on the other side of the carrying box 1, and the electric liquid outlet valve 8 is communicated with the filter box 9, The box 1, the cover plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com