Composite special-shaped flange track system

A flange and track technology, applied in the field of transportation, can solve the problem of insufficient utilization of urban low-altitude resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

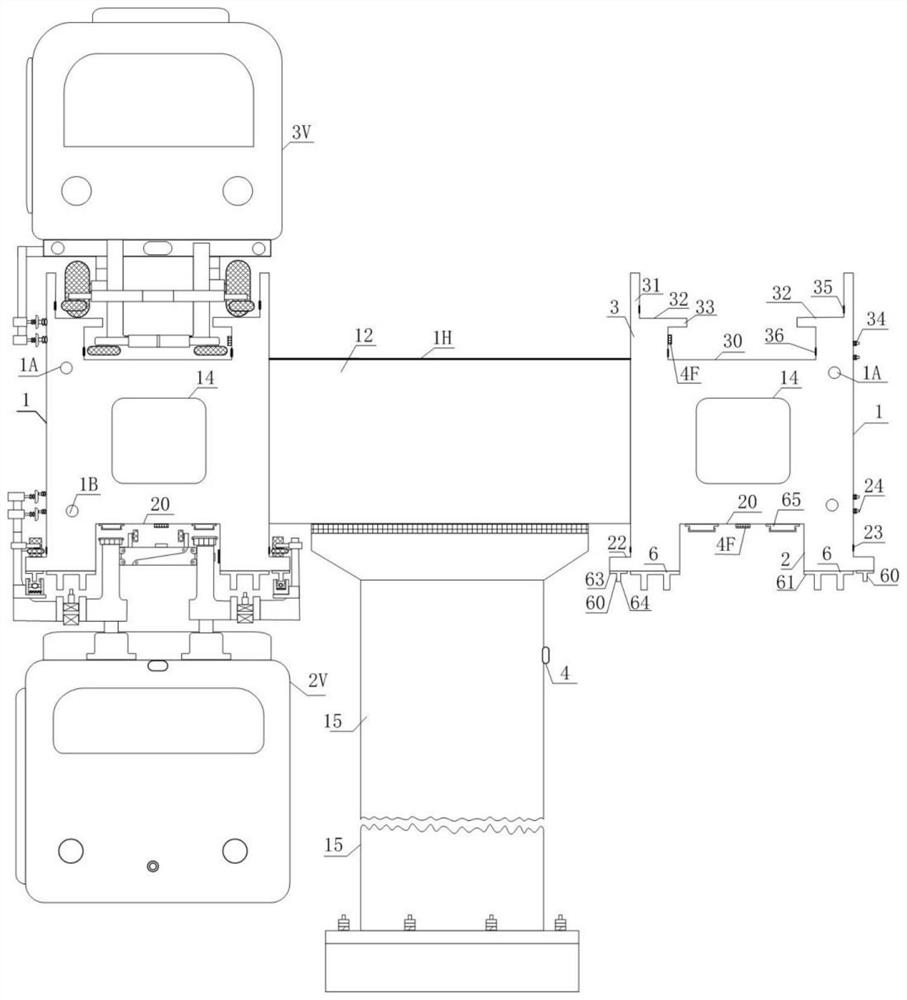

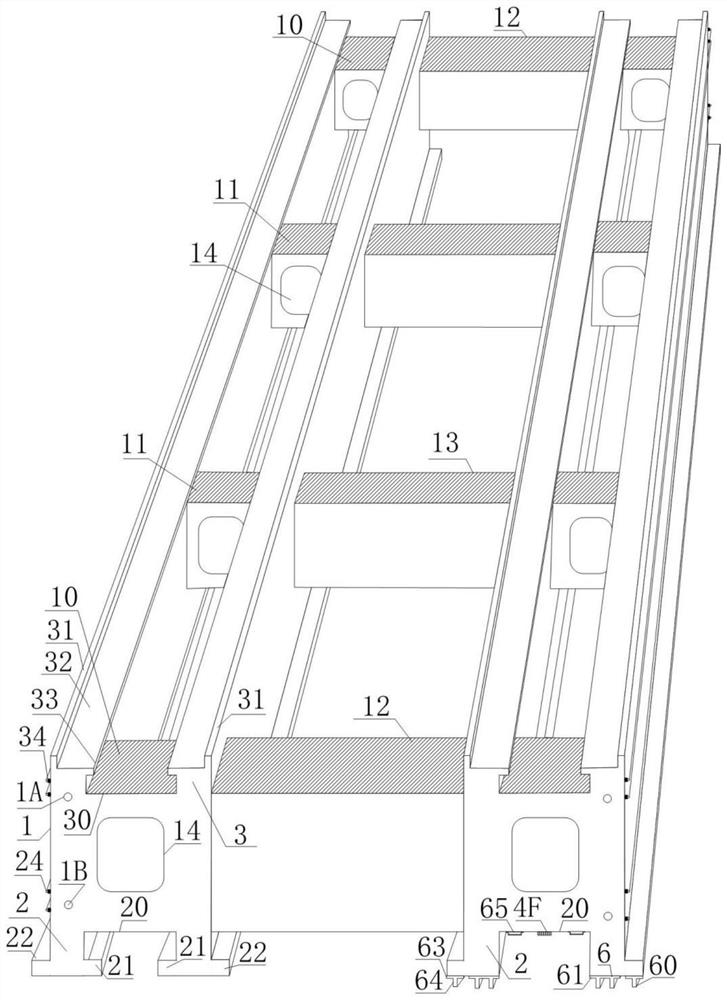

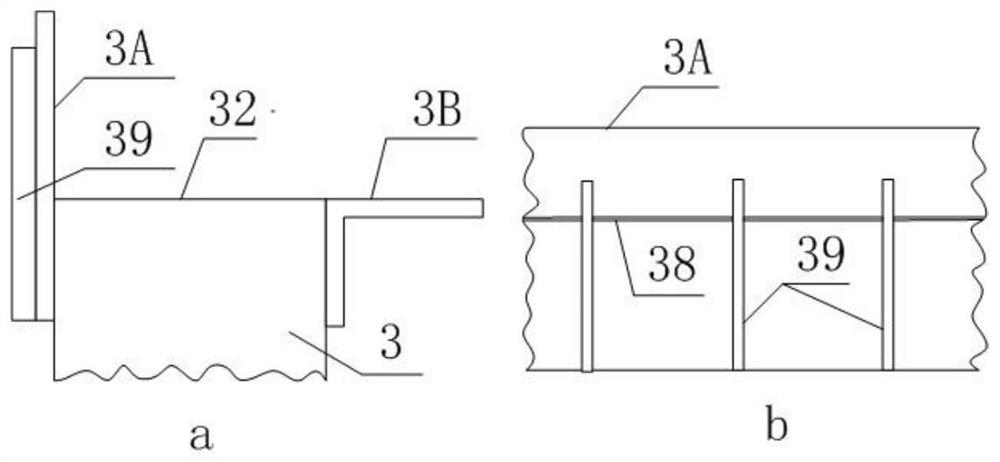

[0009] The invention provides a composite special-shaped flange track system, comprising an H-structure base beam (1), a lower flange special-shaped track (20) and / or an upper flange special-shaped L-track (30), and the H-structure base beam (1) The upper flange special-shaped L track (30) set on the upper flange and the lower flange special-shaped track (20) set on the lower flange are combined up and down to form a composite special-shaped flange track system; or the upper flange special-shaped L track ( 30) or the lower flange profiled track (20) is used alone. The composite special-shaped flange track system further includes an installation beam (12), a connecting middle beam (13), a pier column (15), and a horizontally arranged left and right H-structure base beams (1), which are arranged in parallel longitudinally. A rectangular-structured mounting beam (12) is arranged on the inner side of the front and rear ends, and 0 to 20 (the specific number and spacing are designe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap