Supporting scaffold for bridge construction

A technology for supporting scaffolding and bridge construction, which is applied in the field of supporting scaffolding and construction equipment, can solve the problem that the scaffold is not equipped with anti-fall protection mechanism, and can improve the connection stability, improve the lifting stability, and ensure the tightness of the connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

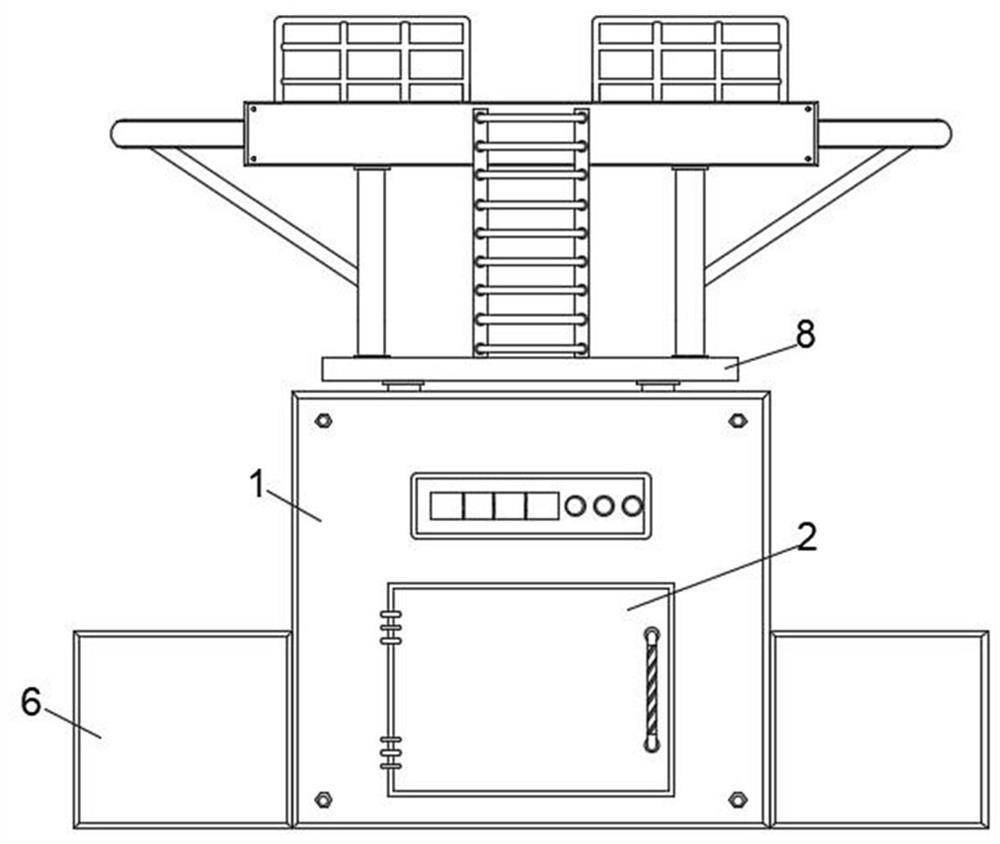

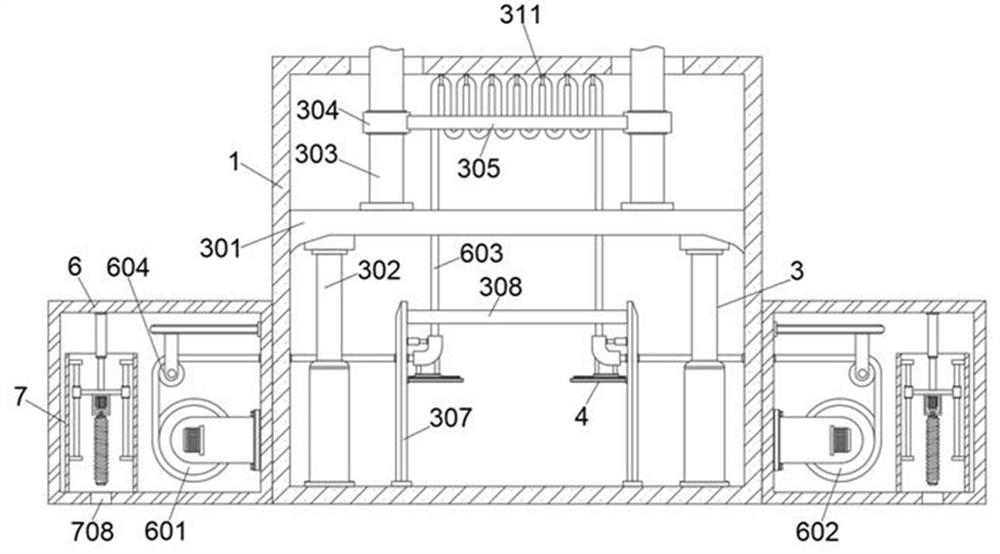

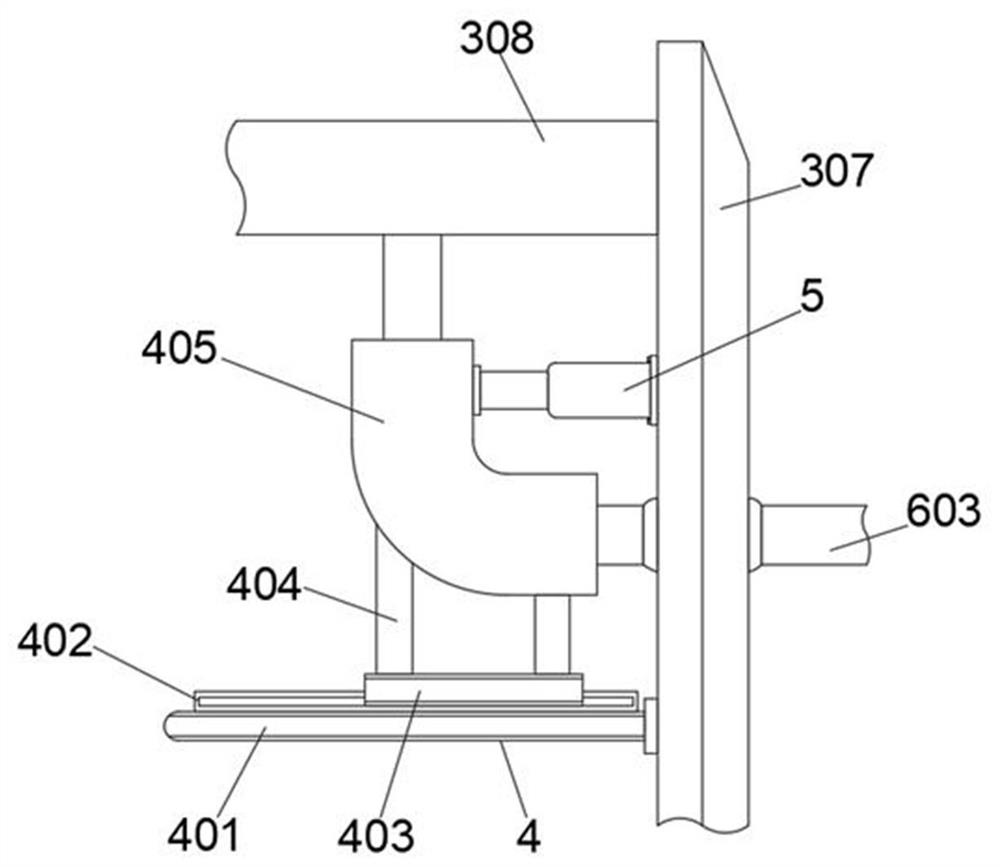

[0041] like Figure 1-2 As shown, a support scaffold for bridge construction includes a support box 1, a box door 2 is arranged on the front of the support box 1, one side of the box door 2 is hinged with the front of the support box 1 through hinges, and the box door 2 is on the other side. A handle is fixedly installed on the front of one side, and a jacking mechanism 3 is arranged inside the support box 1. The jacking mechanism 3 includes a support plate 301 slidably connected between the inner side walls of the support box 1. The bottom of the support plate 301 is connected to the support box. 1. Two symmetrical hydraulic cylinders 302 are fixedly installed between the inner bottom walls. The hydraulic cylinders 302 are used to lift the support plate 301 to provide support for the support column 303 and the balance arm. The top of the support plate 301 is fixedly installed with evenly distributed supports Column 303, the top of the support column 303 passes through the inn...

Embodiment 2

[0049] see Figure 8 As shown, the front of the support box 1 is provided with a processor, and the processor is communicatively connected with an acquisition module, a storage module, a controller, a risk monitoring module and a tensile detection module;

[0050] The acquisition module includes a wind speed sensor, a dust sensor and a displacement sensor arranged on the slider 403, which are arranged on the working platform 802;

[0051] The storage module is used to store data;

[0052] The controller is electrically connected to the hydraulic cylinder 302 and the input end of the first drive motor;

[0053]The risk monitoring module is used for risk monitoring of the environment of the construction site. The specific process of risk monitoring includes: obtaining the wind speed value at the working platform 802 in real time through the wind speed sensor and marking it as the operating wind speed value FY; obtaining the real-time wind speed value at the working platform 802...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com