Reinforced old large-span steel-wood roof truss system and construction method thereof

A large-span, wooden house technology, applied to roofs, long-strip structural components for load-bearing, building maintenance, etc., can solve problems such as the inability to protect ancient buildings and preserve the original architectural style, and achieve the effect of increasing mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

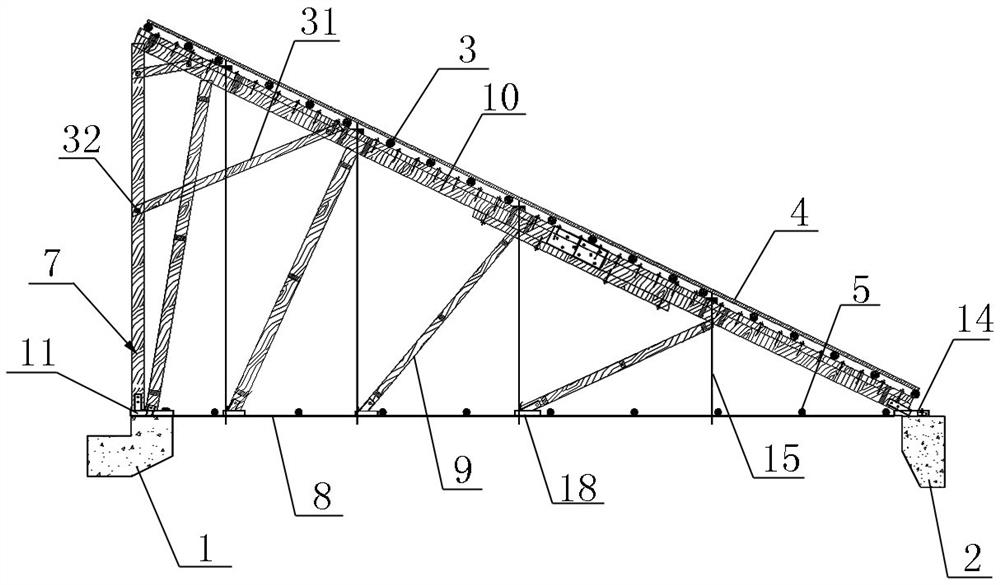

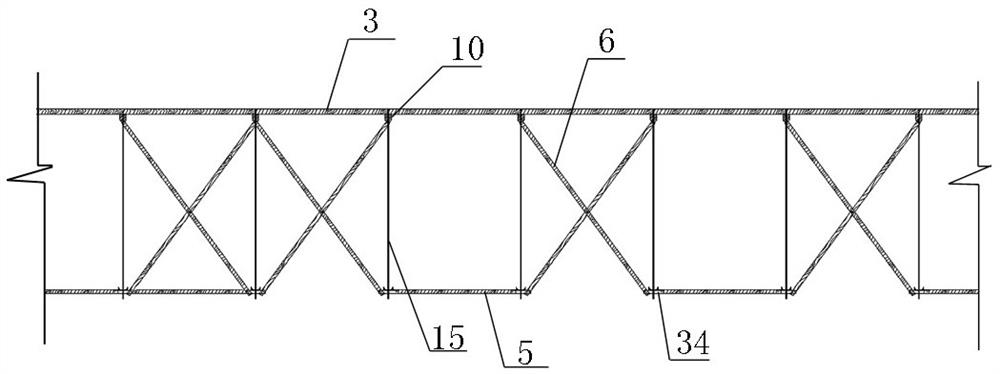

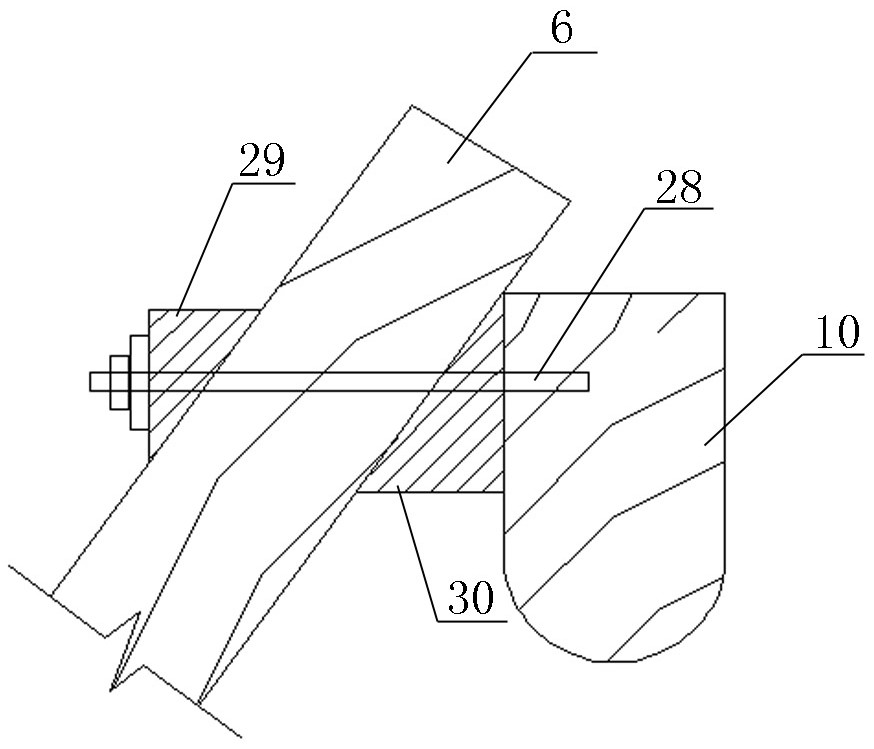

[0061] like Figure 1-22 As shown, this reinforced old long-span steel-wood roof truss system is arranged between the tops of the left main body member 1 and the right main body member 2, including roof truss units, purlins 3, roof panels 4, longitudinal braces 5 and scissors Support 6; the roof truss unit has a group, arranged at intervals along the longitudinal direction; the two ends of each roof truss unit are respectively supported on the left main body member 1 and the right main body member 2; the roof truss unit includes a roof truss support 7, a lower chord 8, a web Rod 9 and upper chord 10; the roof truss support 7 is connected to the left main body member 1 through a first bottom connecting piece 11, the roof truss support 7 includes a vertical brace 7.1, a diagonal brace 7.2 and a first steel sleeve 7.3; the first The steel sleeve 7.3 is sleeved on the lower ends of the vertical support 7.1 and the diagonal support 7.2, and the vertical support 7.1 and the diagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com