Steel tube bundle combined structure and manufacturing method thereof

A combined structure and steel pipe bundle technology, which is applied to structural elements, building components, building structures, etc., can solve the problems of large number of welds and difficult welding of stiffened plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

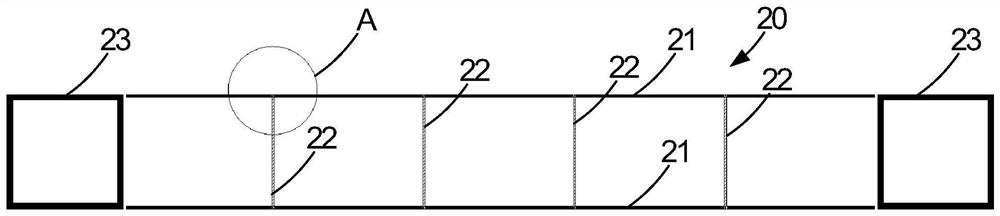

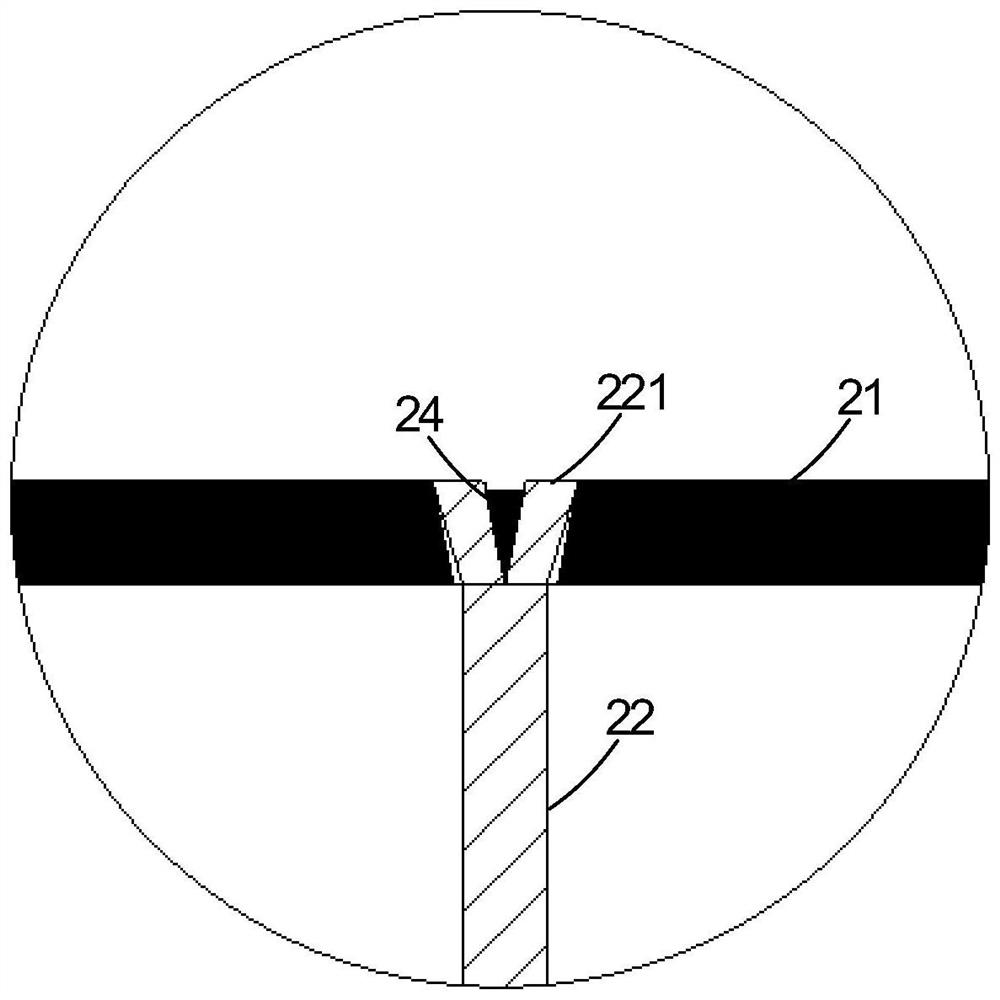

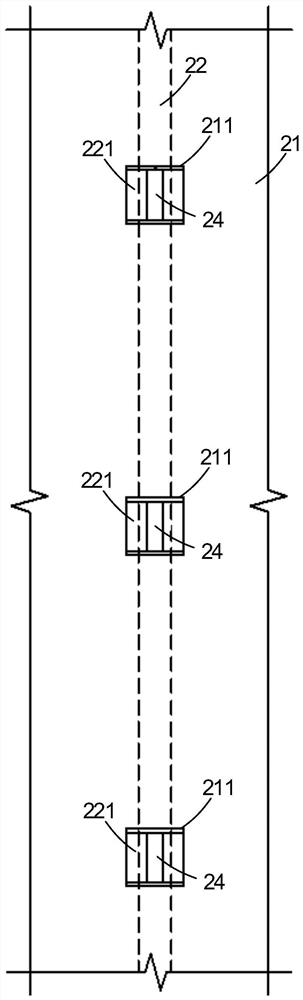

[0032] see figure 1 , The present invention provides a steel tube bundle composite structure and a manufacturing method thereof, which are used to solve the problems that the number of internal stiffening plate welds in the existing steel tube bundle composite structure is large and the welding is difficult. The steel tube bundle composite structure of the present invention adopts tenons. The connecting structure connects the stiffening plate and the outer steel plate. The wedge-shaped blocks are evenly arranged at certain distances along the vertical direction according to the force requirements. When the wedge-shaped blocks are constructed, they are only constructed on the outside, and the wedge-shaped blocks are inserted into the slits of the stiffening plate on the outside. Inside, the wedge-shaped block is knocked into the interior of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com