Active feathering type chimney enclosure structure capable of resisting strong wind and operation method

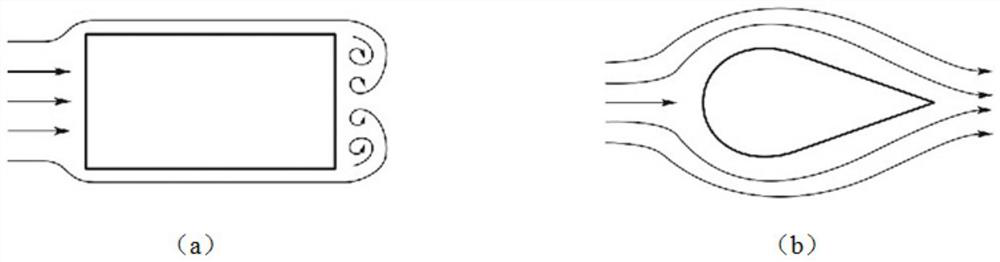

An enclosure structure, feathering technology, applied in the direction of protective buildings/shelters, towers, building types, etc., can solve the problems of low natural vibration frequency, dense distribution, large flexibility, etc. The effect of reducing downwind wind loads and reducing the likelihood of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

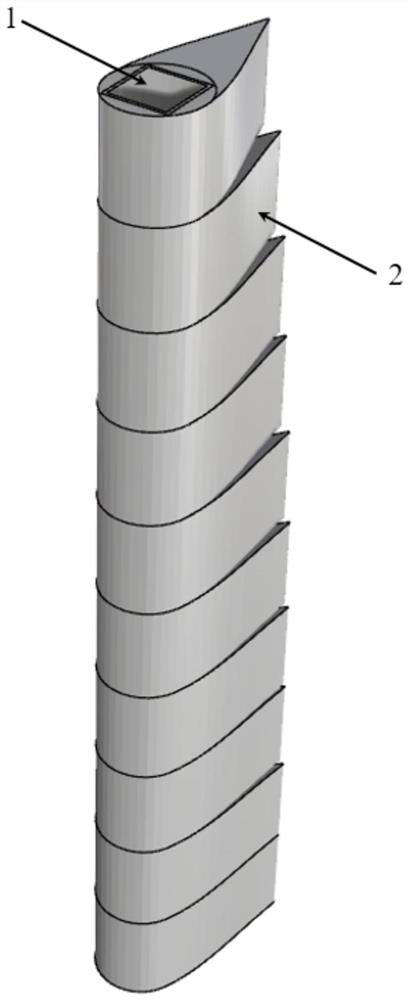

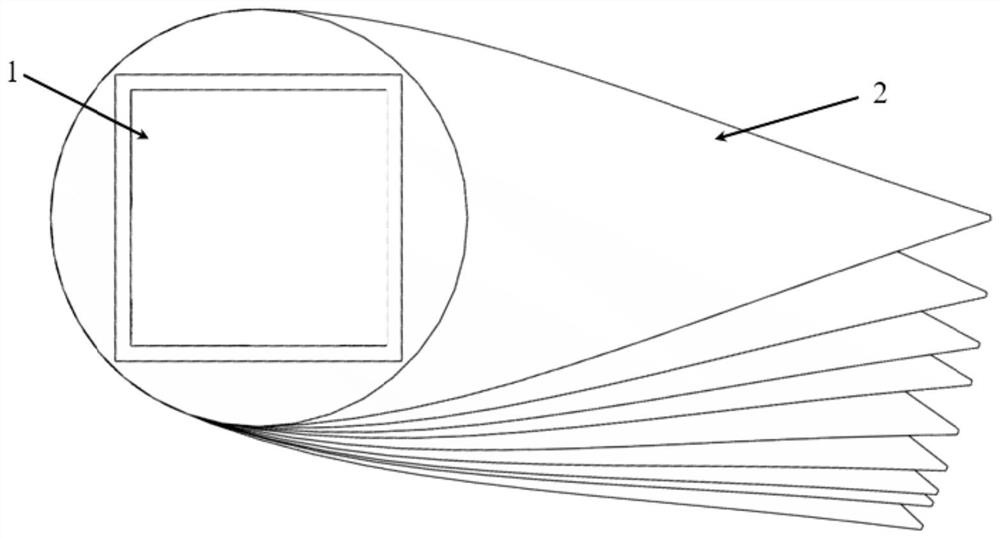

[0044] Embodiment 1 of the present invention provides an active feathering type chimney enclosure structure capable of resisting strong winds, including:

[0045] It is used to set a plurality of leaf element enclosures on the outside of the chimney and a plurality of slide rails that are set on the outside of the chimney. two slides;

[0046] The blade element enclosure structure is streamlined, the top of the blade element enclosure structure is provided with a first pulley group matched with the first slideway, and the bottom of the blade element enclosure structure is provided with a second pulley group matched with the second slideway .

[0047] It can be understood that, in some other embodiments, each slide rail includes a first sub-track with an opening facing upward and a second sub-track with an opening facing downward, and the first sub-track and the second self-track are fixed away from the track; The enclosure structure is streamlined, the top of the blade eleme...

Embodiment 2

[0061] Embodiment 2 of the present invention provides an operation method for an active feathering type strong wind-resistant chimney enclosure structure, using the active feathering type strong wind-resistant chimney enclosure structure described in Embodiment 1 of the present invention, including:

[0062] When encountering strong winds, the blade element enclosures of each streamline body can slide relative to each other according to their own aerodynamic effects, and each segmented blade element enclosure can actively pitch in the wind. So that each leaf element always maintains the feathering state of the wind direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com