Drawing clamping stop mechanism and water outlet device

A technology for pulling the card and pulling the tube, applied in the kitchen and bathroom field, can solve the problems of inconvenient user other operations, unfavorable user operation and use, affecting the structure configuration mode, etc., to improve the structure configuration and operation mode, simplify the water outlet mode, The effect of enhancing the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

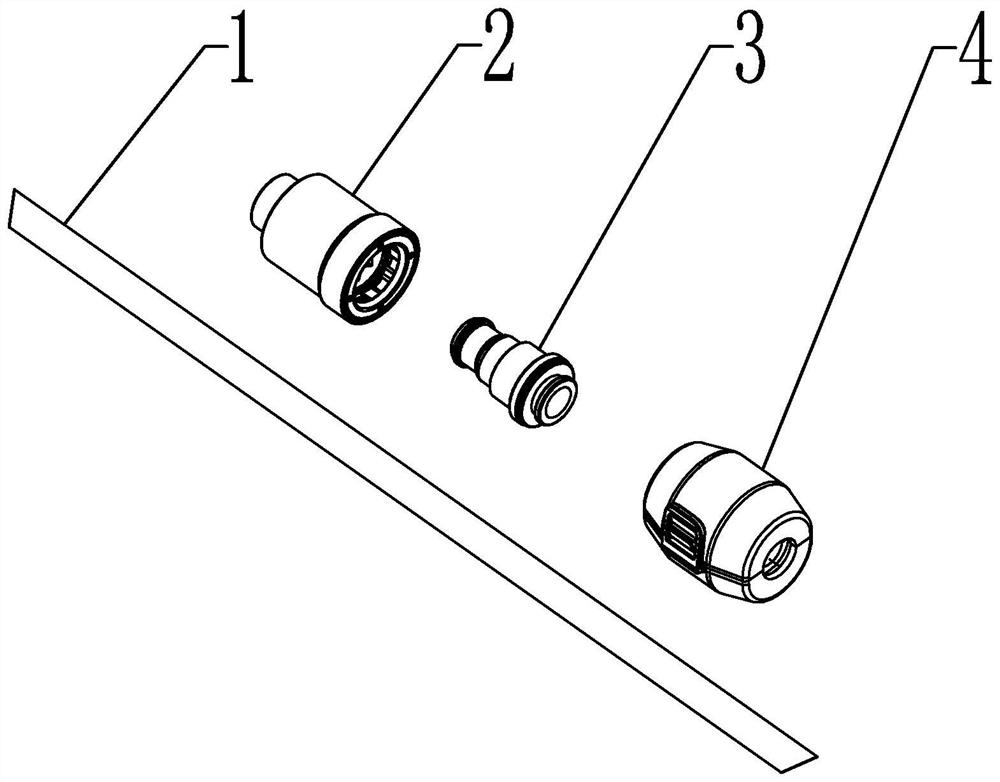

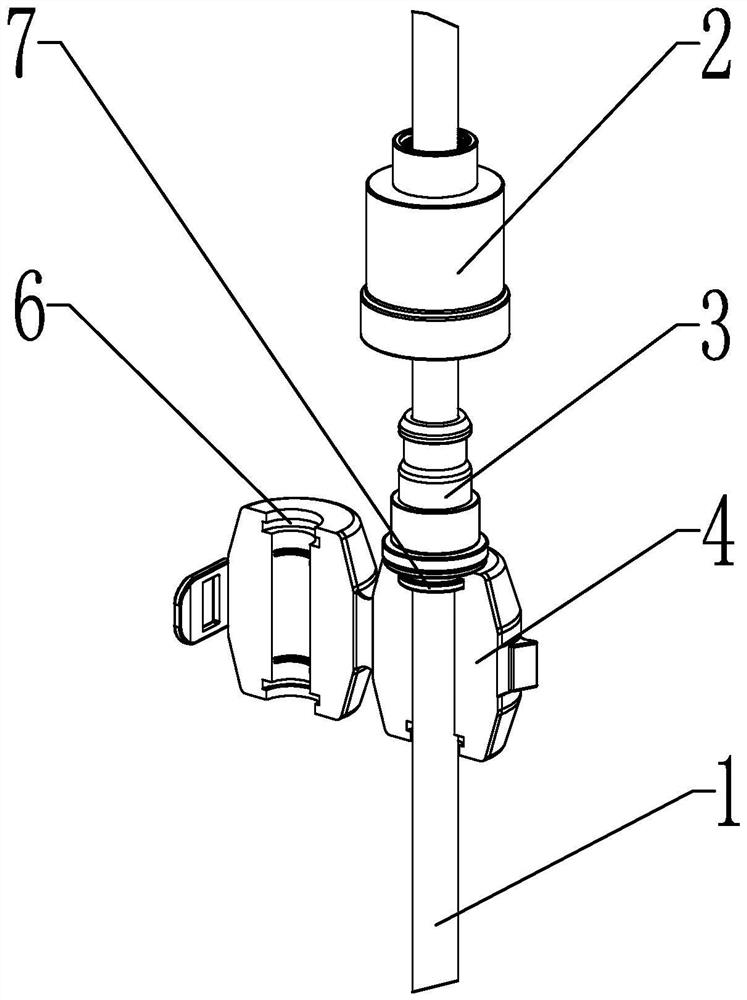

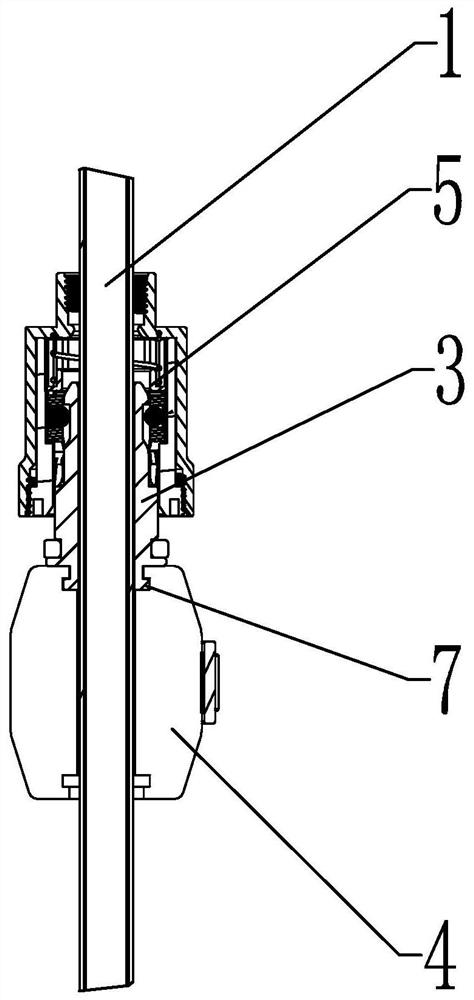

[0038] combine Figure 1 to Figure 12 , this embodiment provides a pull-and-stop mechanism, including a pull-out tube 1, a limit body 2 movably sleeved on the pull-out tube 1, and a guide sleeve 3 and a guide sleeve 3 disposed on the pull-out tube 1 Return piece 4. A transmission assembly 5 is arranged in the limiting body 2 . After pulling the pull-out tube 1 once, the guide sleeve 3 is locked in the limiting main body 2 under the cooperation of the transmission assembly 5, correspondingly, the pull-out tube 1 is limited and fixed in its use position. After pulling the drawing tube 1 again, the guide sleeve 3 can release its position limit in the limiting body 2 under the cooperation of the transmission assembly 5, so that the guiding sleeve 3 is in a free state in the limiting body 2, and when released. After pulling the tube 1 , the pulling tube 1 is reset to its initial position under the driving of the return member 4 . Wherein, the drawing pipe 1 is provided with a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com