LNG (Liquefied Natural Gas) gasifier

A gasifier and natural gas technology, applied in the field of LNG gasifier, can solve the problems of low heat exchange efficiency and gasification efficiency, and achieve the effect of improving heat exchange efficiency and ensuring gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Referring to the accompanying drawings, the specific embodiments are as follows:

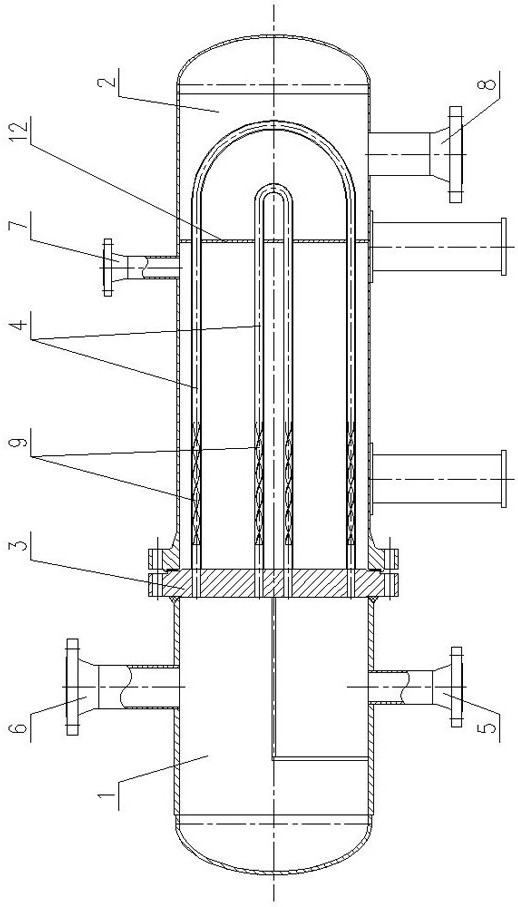

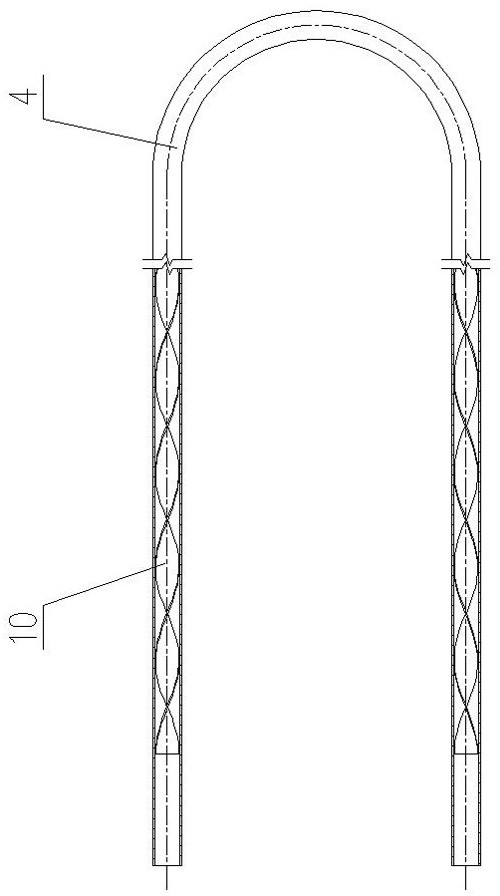

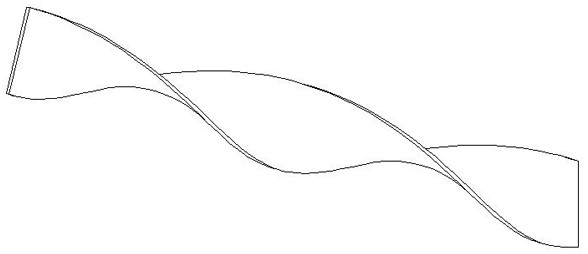

[0019] like figure 1 As shown, an LNG gasifier includes a tube box 1, a shell 2 and a heat exchange tube bundle. The heat exchange tube bundle includes a tube sheet 3, a support plate 12 and a plurality of U-shaped tubes 4. The two ends of the tube sheet 3 are respectively connected to The tube box 1 is connected to the shell 2, the support plate 12 and a plurality of U-shaped tubes 4 are located inside the shell 2, the two ends of the U-shaped tubes 4 are respectively connected with different through holes on the tube plate 3, and the U-shaped tubes 4 pass through. It is provided on the support plate 12 , and the support plate 12 is connected with the inner wall of the housing 2 , so as to support and fix the plurality of U-shaped tubes 4 .

[0020] like figure 1 As shown, the pipe box 1 is divided into an air inlet chamber and an air outlet chamber, the side wall of the air inlet cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com