A kind of low-quality coal segmental coupled gasification device and gasification method

A technology of gasification device and low-quality coal, which is applied in the direction of granular/powdered fuel gasification, joint combustion relief, and production of combustible gas. Strong adaptability, reduced energy consumption, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

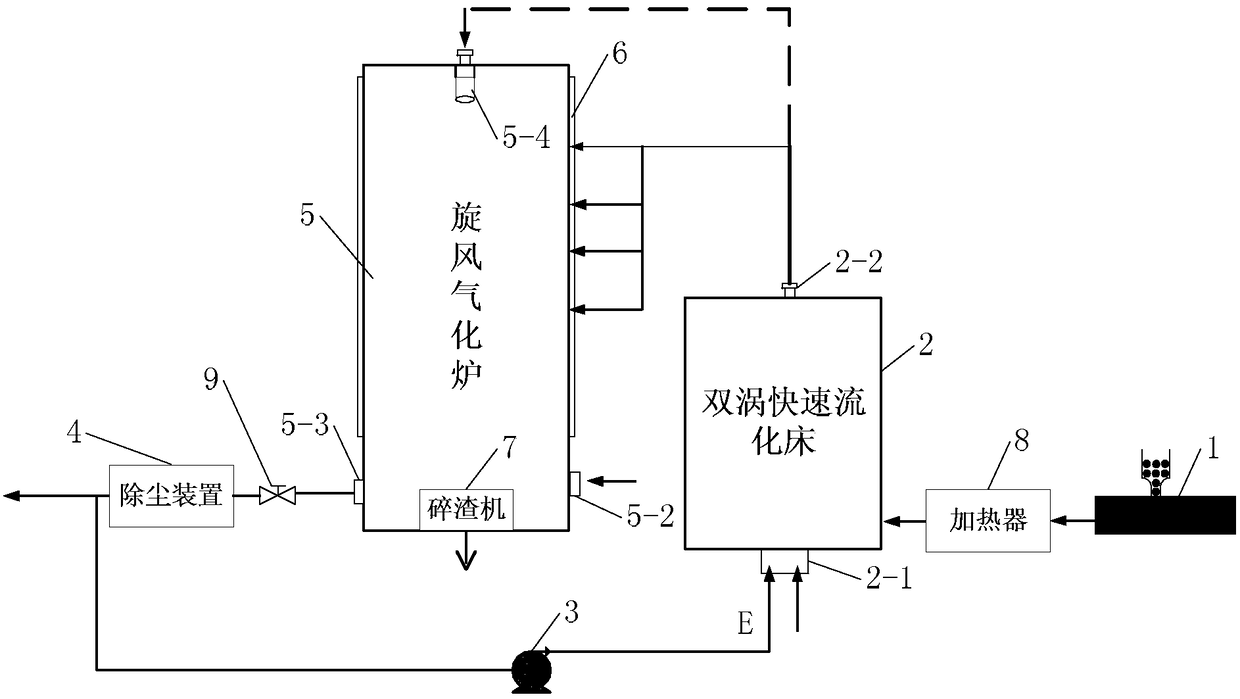

[0073]Specific implementation mode two: see figure 1 To illustrate this embodiment, the difference between this embodiment and the staged coupled gasification device for low-quality coal described in Embodiment 1 is that the optimum working temperature of the cyclone gasifier 5 is 1250°C.

[0074] In this embodiment, the equilibrium analysis shows that when municipal solid waste MSW is used as raw material, when the working temperature of the twin-vortex fast fluidized bed is 600°C, the optimum working temperature of the cyclone gasification furnace 5 is 1253°C, and the carbon conversion rate is as high as 98.9%, oxygen consumption is about 0.287, cold gas efficiency is about 82%.

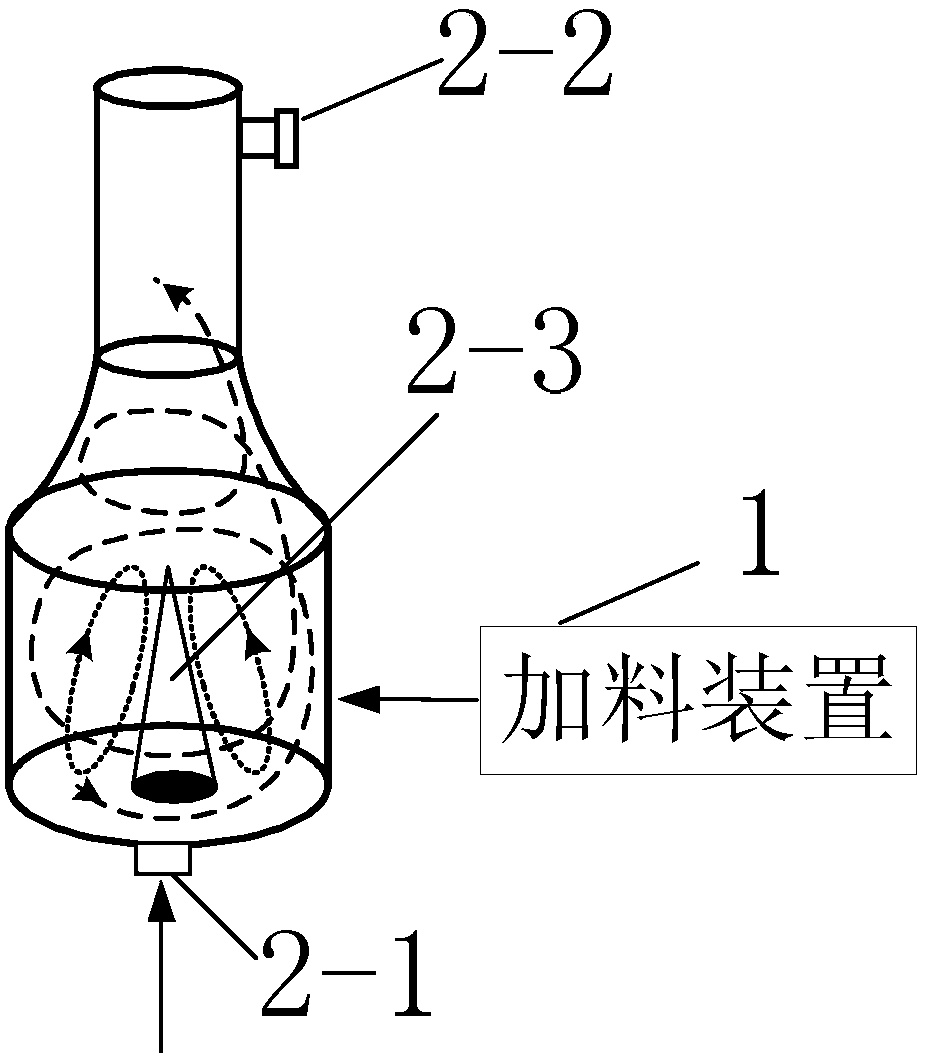

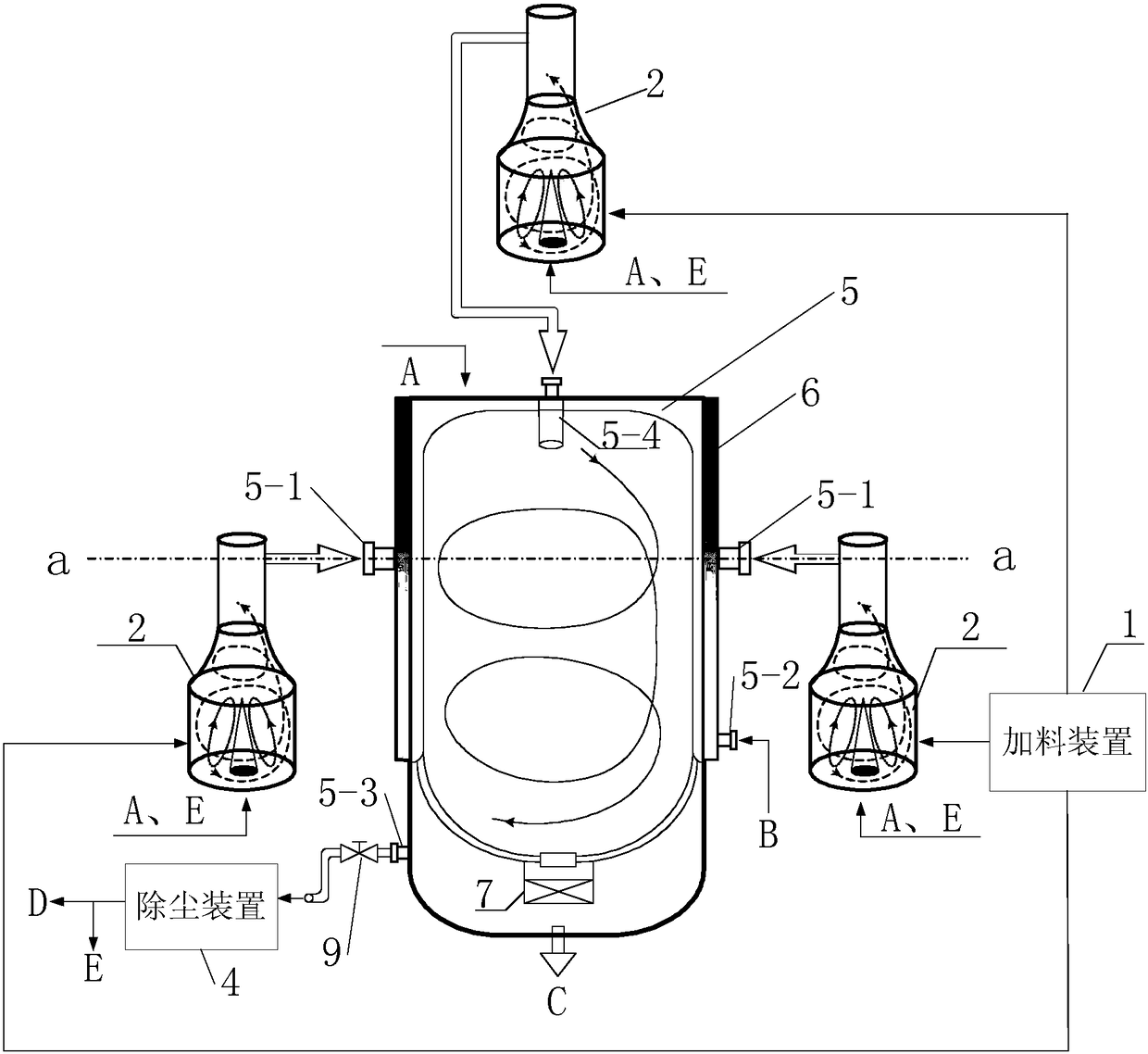

[0075] Specific implementation mode three: see figure 1 with figure 2 To illustrate this embodiment, the difference between this embodiment and the staged coupled gasification device for low-quality coal described in Embodiment 1 is that the twin-vortex fast fluidized bed 2 is divided into two p...

specific Embodiment approach 9

[0091] Specific embodiment nine: adopt the gasification method realized by a kind of low-quality coal segmental coupling gasification device described in specific embodiment one, the specific process of this method is:

[0092] Step 1: Pass the inferior coal particles with a diameter less than 10mm through the feeding device 1 with N 2 or CO 2 Pressurize to 4MPa and send it into the twin-vortex fast fluidized bed 2, and at the same time feed the gasification agent tangentially through the No. 1 gasification agent inlet 2-1 at the bottom of the double-vortex fast fluidized bed 2, 2. The internal working temperature is within the range of 500°C to 980°C. The low-quality coal particles are pyrolyzed, and the raw coal gas generated spirals upward in the double-vortex fast fluidized bed 2 and is sprayed into the cyclone gasifier 5;

[0093] Step 2: Keep the working temperature of the cyclone gasifier 5 within the range of 1200°C to 1300°C, feed raw coal gas and gasification agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com