Process and system for testing refrigeration air volume of air conditioner

An air-conditioning refrigeration and testing system technology, applied in the field of air-conditioning, can solve the problems of consuming workers' physical strength and energy, hand shaking, and small measurement range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

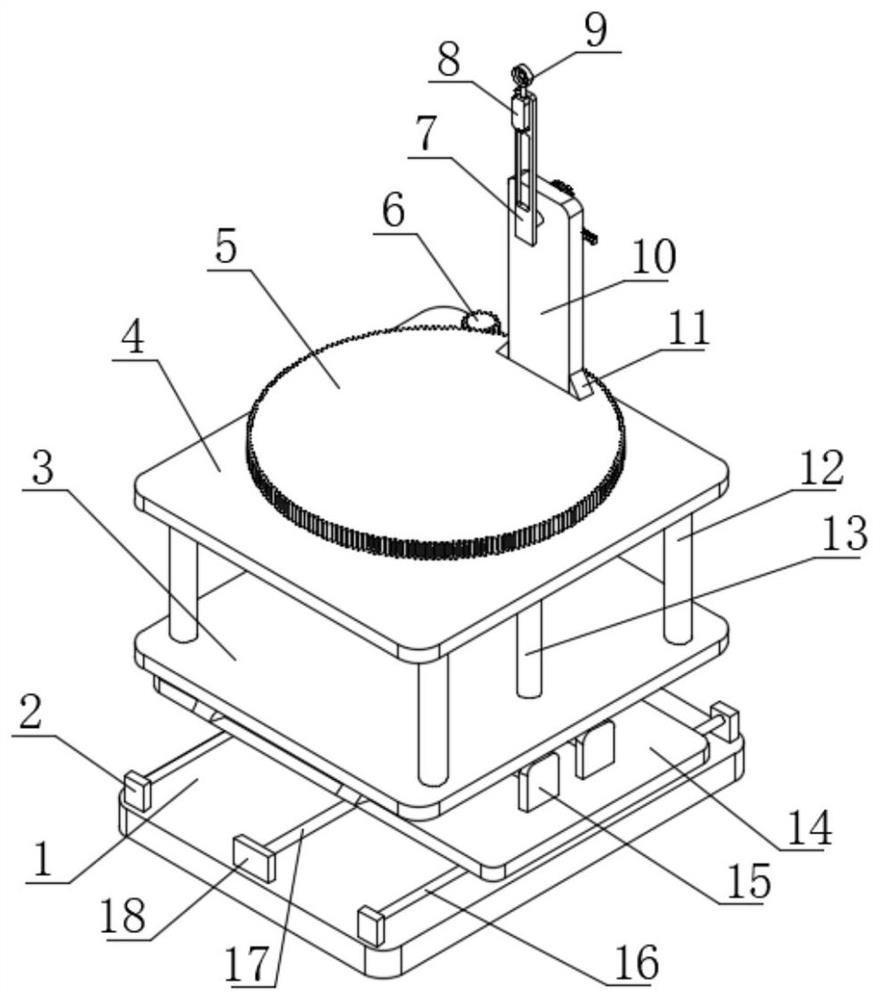

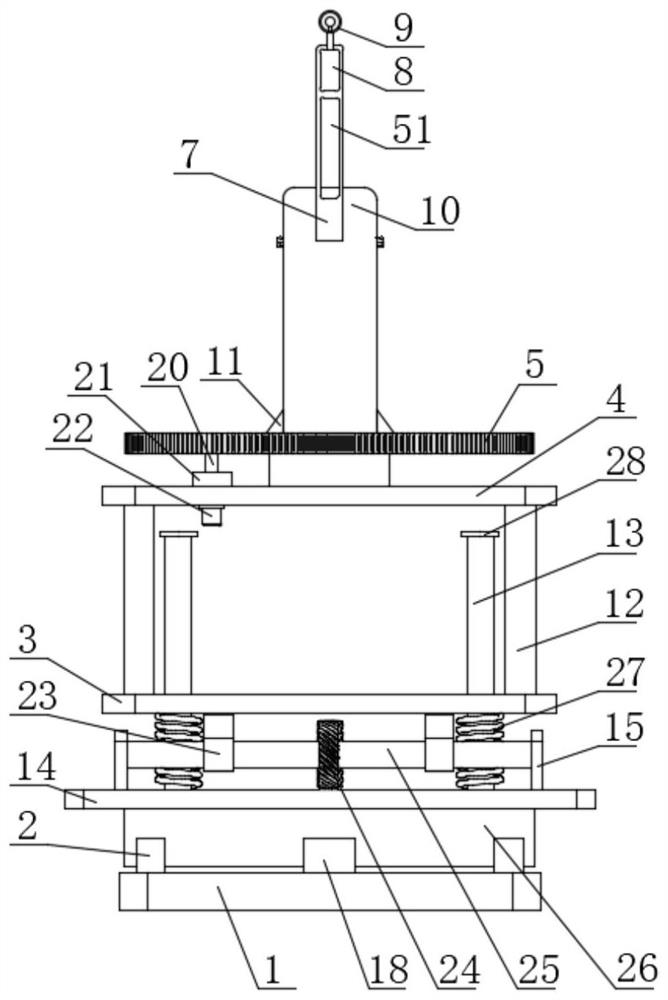

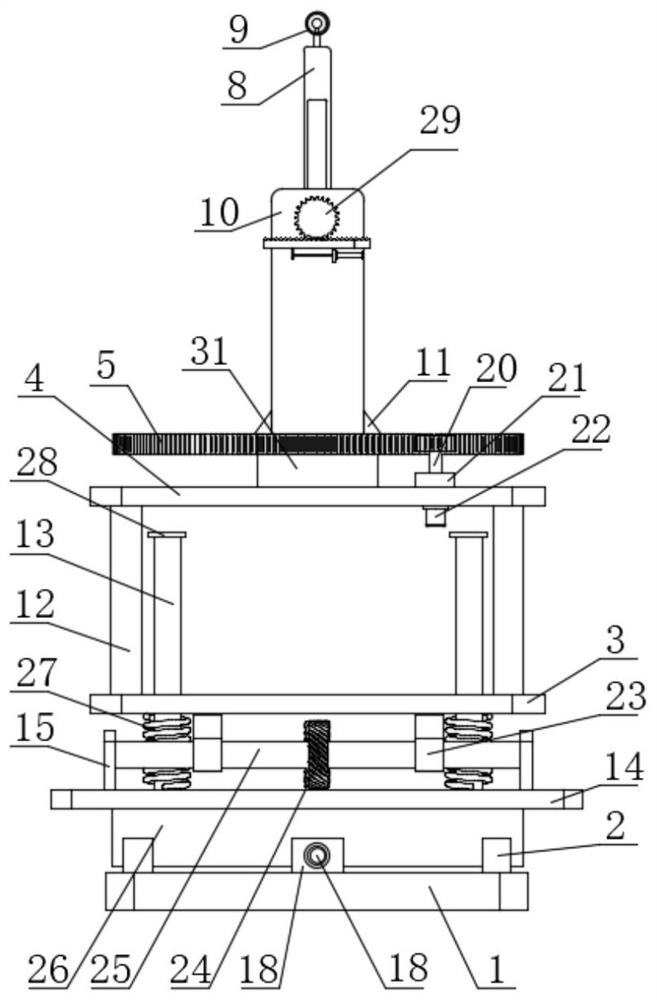

[0062] Example 1: as Figure 1-15 As shown in the figure, an air-conditioning refrigeration output air volume testing system includes a base 1, two first vertical plates 2 are welded symmetrically on both sides of the top of the base 1, and a third vertical plate 18 and a fourth vertical plate 18 are welded on the top of the base 1 respectively. Plate 19, the same sliding rod 16 is welded on one side of the two first vertical plates 2 that are close to each other, one side of the fourth vertical plate 19 is fixedly installed with a translation motor 30, and the output shaft of the translation motor 30 is welded with a screw rod 17. One end of the screw rod 17 penetrates the fourth vertical plate 19 and is rotatably connected to one side of the third vertical plate 18. Two support plates 26 are threadedly connected to the outer wall of the screw rod 17, and one end of the two sliding rods 16 penetrates through two There are two support plates 26 extending to one side of the sup...

Embodiment 2

[0084] Embodiment 2: as Figure 16-20 The difference between this embodiment and the first embodiment is that the sides of the pressure plate 8 and the vertical plate 10 close to each other are respectively provided with a second arc-shaped groove 49 and a first arc-shaped groove 34. , the outer wall of the anemometer probe 9 is in contact with the inner wall of the second arc-shaped groove 49 and the inner wall of the first arc-shaped groove 34, and two positioning pins 48 are symmetrically welded on the top of the side of the pressure plate 8 close to the vertical plate 10, and the vertical Two positioning holes 32 are symmetrically arranged at the top of one side of the plate 10 close to the pressing plate 8, one end of the positioning pin 48 penetrates the positioning holes 32 and extends to one side of the vertical plate 10, and two tie rods 47 are symmetrically welded to the bottom of one side of the pressing plate 8. One end of the pull rod 47 penetrates the vertical pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com