Auxiliary detection system and detection method for drainage pipeline in corrosive environment

A technology for drainage pipes and corrosive environments. It is applied in the directions of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of inability to detect real-time changes in pipelines, inability to realize pipeline detection, and limited detection methods, and reduce the number of times. , to ensure accuracy and authenticity, and to detect the effect of multiple dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

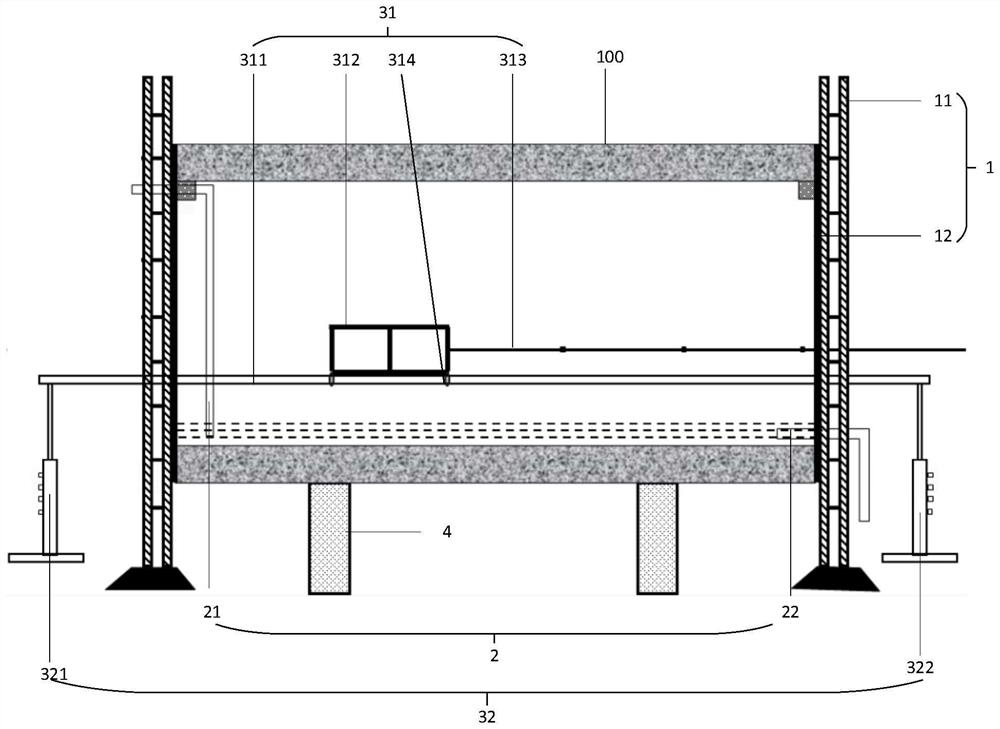

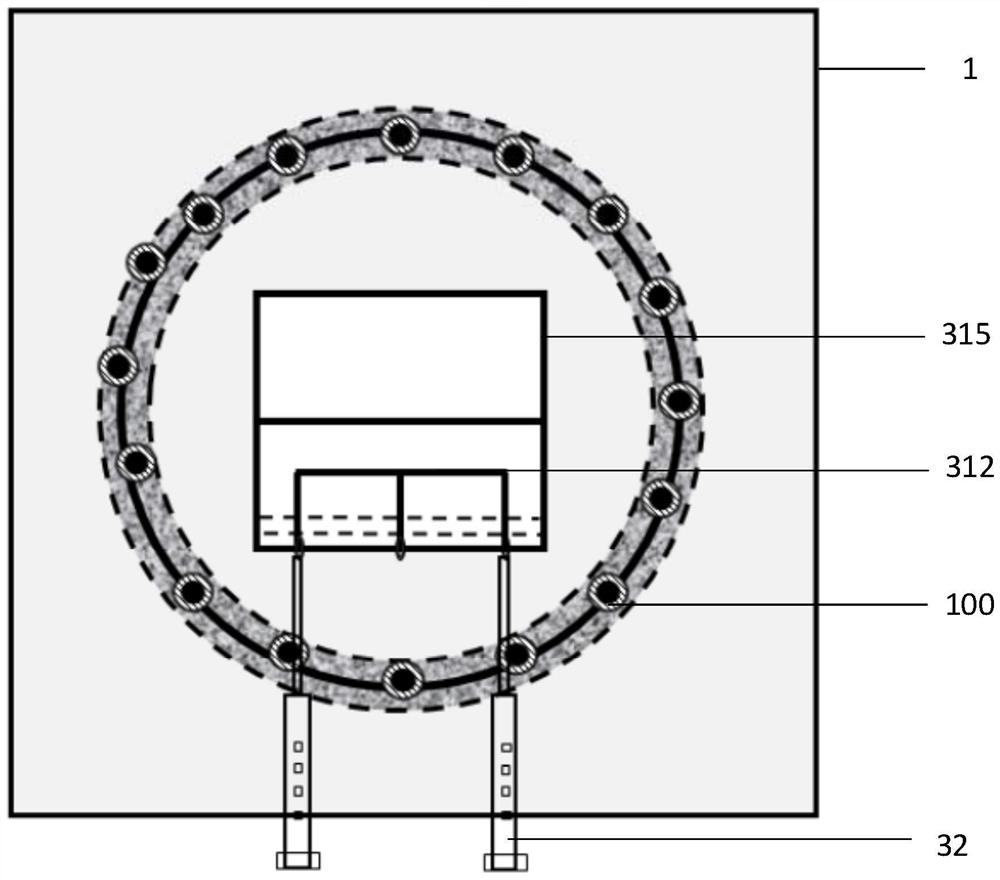

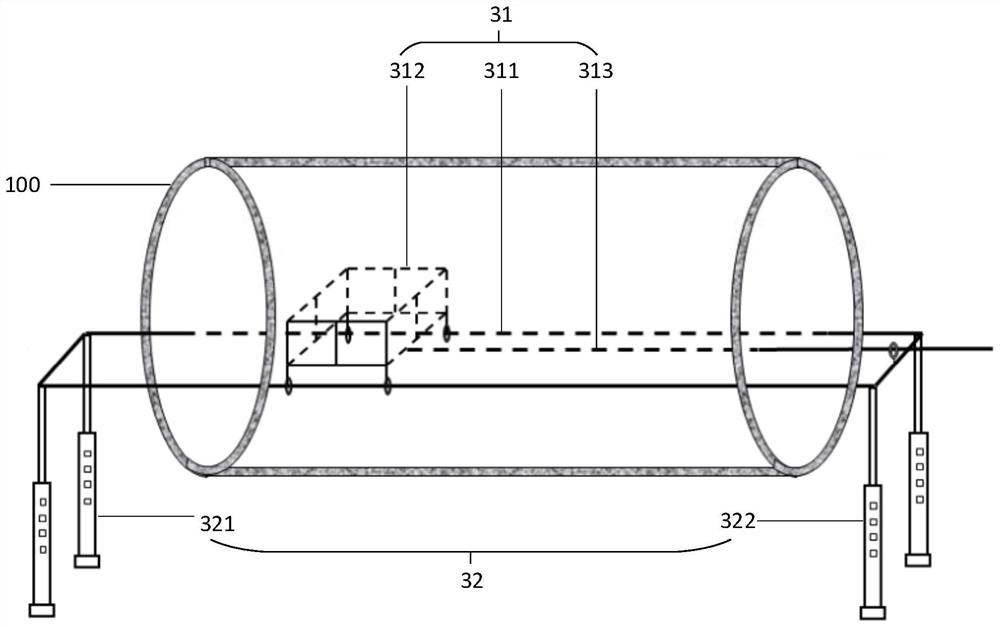

[0089] Example 1: Combining Figure 1 to Figure 3 Illustrating this embodiment, the pipeline 100 to be tested provided in this embodiment, that is, the inner diameter of the reinforced concrete pipeline is set to 1.5m, the pipe length is set to 3m, and the corrosion solution is 5% dilute sulfuric acid. The movable adjustment detection platform 3 has a bearing side length of 0.8m and a bearing mass of 150kg. The height of the first adjustment bracket 321 and the second adjustment bracket 322 can be adjusted in a range of 0.3-0.8m, and the adjustment rod 313 can be adjusted in a range of 0-3m. The reinforced concrete pipe is lying on the support bearing of the wooden pile, and the corrosion solution gathers the lower part of the reinforced concrete pipe. The two-end blocking device 1 is fixed on both ends of the reinforced concrete pipeline by blocking plates 11 and bolts, and a corrosion-resistant rubber ring with a width of 4 mm is pasted in the middle for sealing.

Embodiment 2

[0090] Example 2: Combination figure 1 and figure 2 Describing this embodiment, in the present invention, the movable detection platform is installed on the movable slide rail 311 through the movable pulley 314, and the adjustable rod 313 can be pushed to change the measurement position of the movable detection platform 3 in different sections of the reinforced concrete pipeline, and the first adjustment bracket can be adjusted. The height of 321 and the second adjusting bracket 322 can be changed and the height of the test platform 3 can be adjusted and moved, and a guardrail 315 is provided around the test table 312 to ensure the safe operation space of personnel and equipment.

Embodiment 3

[0091] Embodiment 3: After the sulfuric acid / sulfate corrosion is completed, the sulfuric acid corrosion solution in the reinforced concrete pipeline can be emptied through the corrosion solution circulation device 2, and after dredging and cleaning, the corrosion characteristics of the inner wall of the corrosion solution circulation device 2 are tested in turn. and residual mechanical properties.

[0092]According to the above method, the corrosion status of the corroded pipeline can be detected and monitored at the same time during the corrosion process, the continuity of the internal corrosion status of the reinforced concrete can be ensured, and the safety distance between the personnel and the corrosion layer and corrosion products can be ensured during the test process. To ensure the safety of personnel, it is feasible and safe to use sulfuric acid / sulfate and other precursor chemicals for corrosion and life cycle monitoring of large-diameter reinforced concrete pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com