XY direction included angle measurement and motion compensation method based on image microscopic scanning platform

A scanning platform and motion compensation technology, which is applied in the fields of medical information collection and detection and clinical medicine, can solve the problems that the measurement method is difficult to ensure the verticality requirements of the scanning platform, the image cannot meet the work requirements, and the image content does not match, so as to improve the image quality. Processing efficiency, maintaining stable image acquisition, and avoiding the effect of image shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, not all of the embodiments. The embodiments of the present invention, and all other embodiments obtained by those skilled in the art without creative efforts, fall within the protection scope of the present invention.

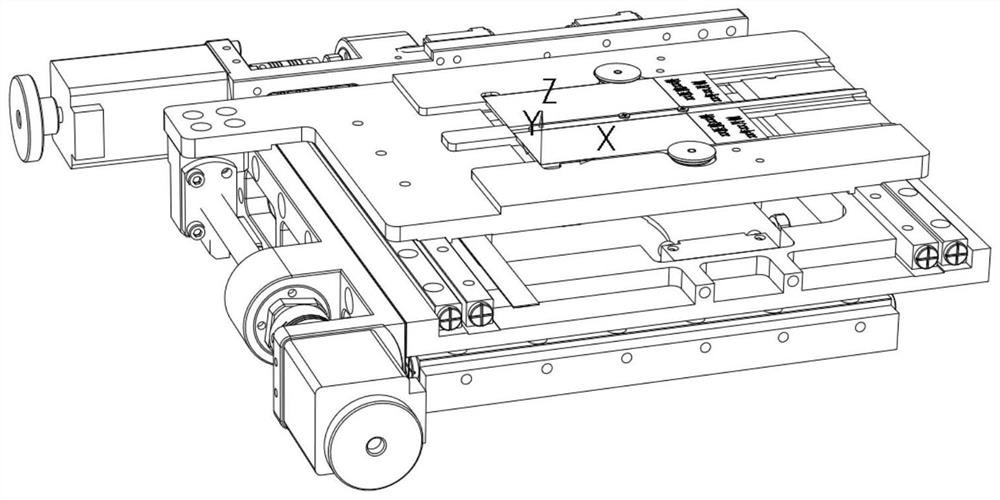

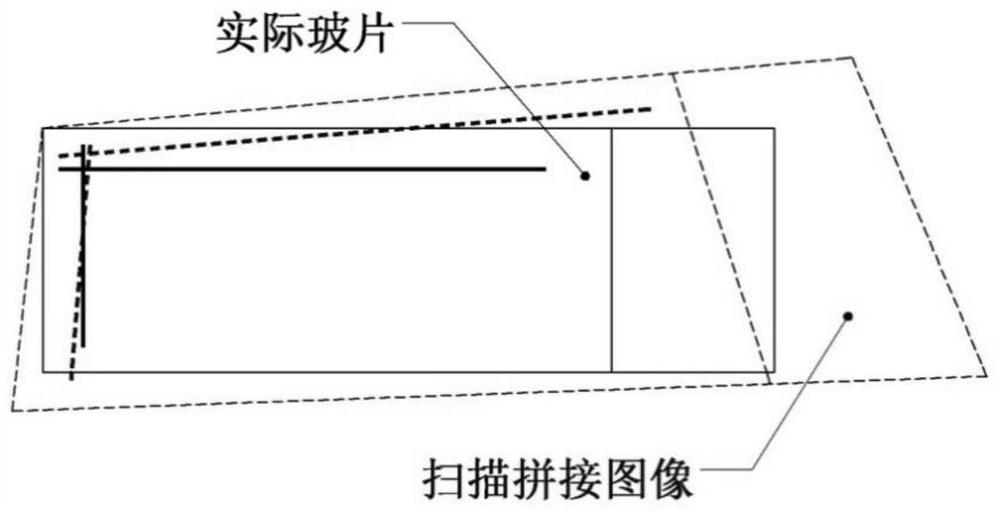

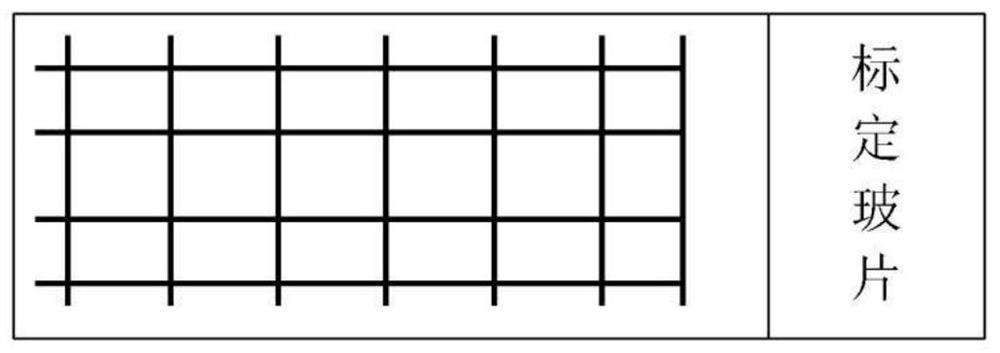

[0033] The invention proposes a method for measuring and compensating the angle between the XY directions of an image microscopic scanning platform, and measures the angle of the current scanning platform movement direction based on the method of recognizing and splicing the images of the calibration line of the specially-made calibration glass slide. In an ideal state, the angle between the scanning platform along the X direction and its step movement along the Y d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com