Control device and method of flexible battery thermal management system, battery and vehicle

A technology of battery management system and thermal management system, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor thermal management consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

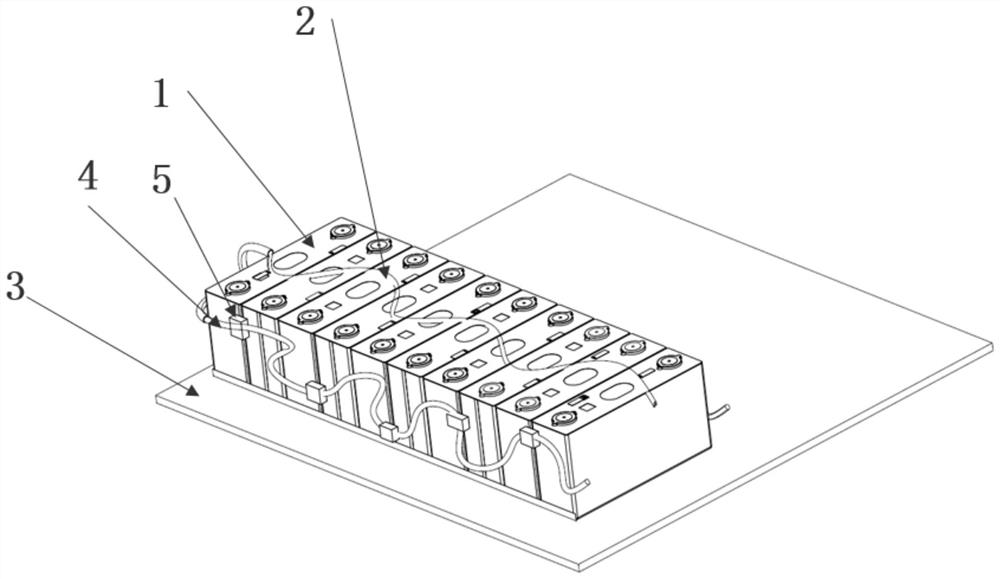

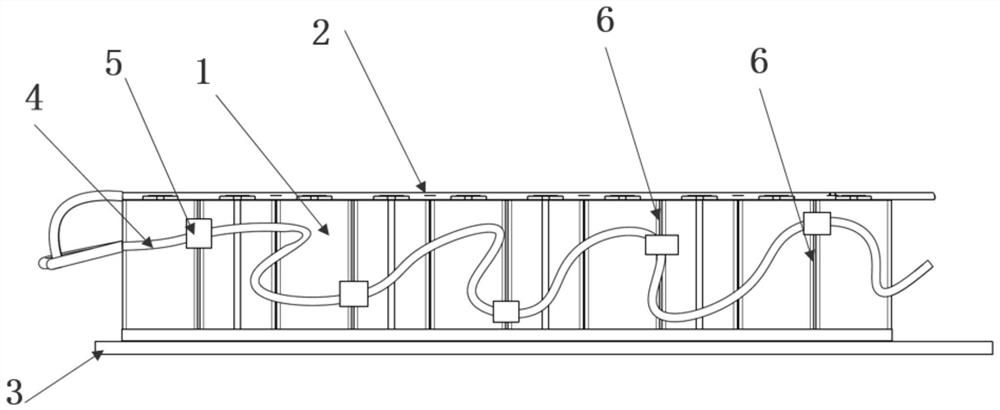

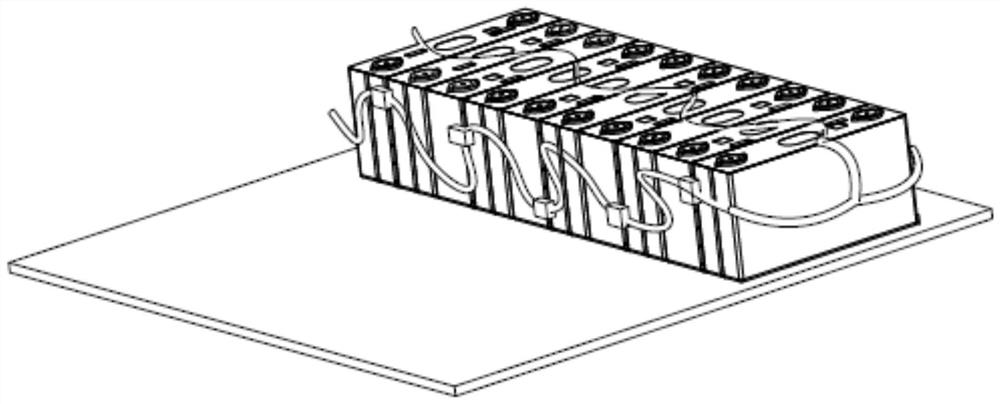

[0051] see Figure 1-Figure 3 , a control device for a flexible battery thermal management system, comprising a battery cell 1 , a flexible top tube 2 , a lower battery case 3 , a flexible side tube 4 , an electromagnetic fixer 5 and a sliding rod 6 .

[0052] The lower end of the flexible top tube 2 is fixed on the upper end of the battery cell 1; the sliding rod 6 is fixed on both sides of the battery cell 1; the flexible side pipe 4 is fixed on the sliding rod 6 by the electromagnetic holder 5; One end of the flexible side pipe 1 is connected to the vehicle water pump, and the vehicle water pump is connected to the vehicle HCU; the other end of the flexible side pipe 1 is connected to one side of the flexible side pipe 4 on both sides of the battery cell 1; The other side of the flexible side pipe 4 is connected to the circuit of the battery thermal management system BMS; the lower end of the battery cell 1 is fixed on the lower battery box 3; the electromagnetic holder 5 i...

Embodiment 2

[0060] see Image 6 , a control method of a control device of a flexible battery thermal management system, comprising the following steps:

[0061] Step 1. The battery management system BMS collects the temperature of the battery cell 1;

[0062] Step 2: The battery management system BMS judges according to the collected temperature of the battery cell 1, judges which control mode it is in, and executes the corresponding control mode; wherein, the control modes are divided into three types: no operation mode, thermal management mode mode, thermal runaway mode;

[0063] Define the maximum temperature of the battery cell 1 collected by the battery management system BMS as TM; the minimum temperature of the battery cell 1 collected by the battery management system BMS as TN; the temperature difference is TC, TC=TM-TN; the temperature difference is every second Calculated from the implementation test data; set the thermal runaway trigger temperature as TS, and the thermal manag...

Embodiment 3

[0070] This embodiment also provides a battery, which includes the control device of the above-mentioned flexible battery thermal management system, including a battery cell 1 , a flexible top tube 2 , a lower battery box 3 , a flexible side tube 4 , and an electromagnetic holder. 5 and slide bar 6.

[0071] The lower end of the flexible top tube 2 is fixed on the upper end of the battery cell 1; the sliding rod 6 is fixed on both sides of the battery cell 1; the flexible side pipe 4 is fixed on the sliding rod 6 by the electromagnetic holder 5; One end of the flexible side pipe 1 is connected to the vehicle water pump, and the vehicle water pump is connected to the vehicle HCU; the other end of the flexible side pipe 1 is connected to one side of the flexible side pipe 4 on both sides of the battery cell 1; The other side of the flexible side pipe 4 is connected to the circuit of the battery thermal management system BMS; the lower end of the battery cell 1 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com