Control device capable of being remotely operated for maintenance of transformer substation

A remote operation and control device technology, applied in substation/switch layout details, substations, closed substations, etc., can solve the problems of reducing the overall applicable life, inconvenient use, and unable to guarantee the overall safety of the device, so as to improve the applicable life, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

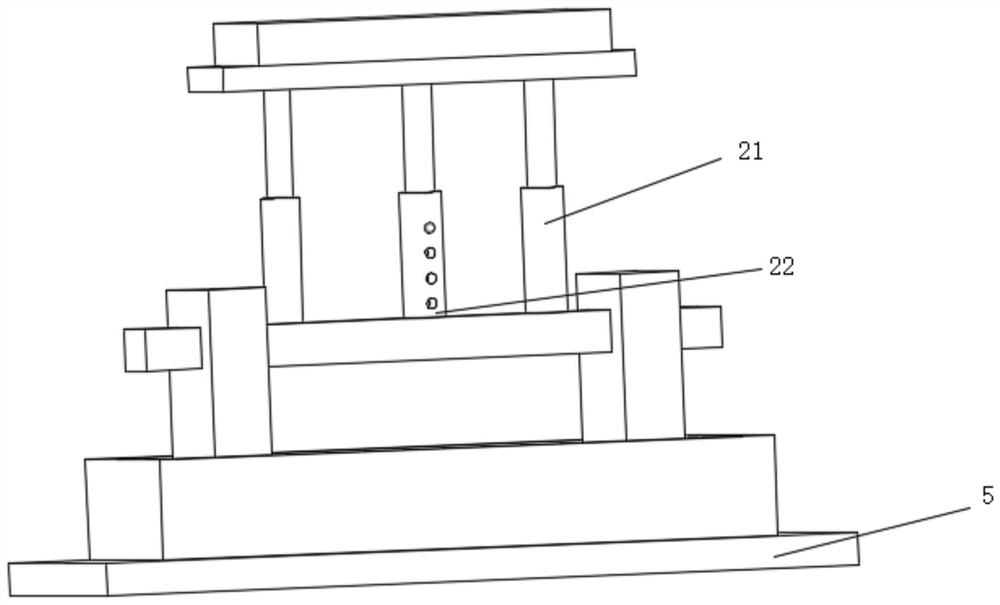

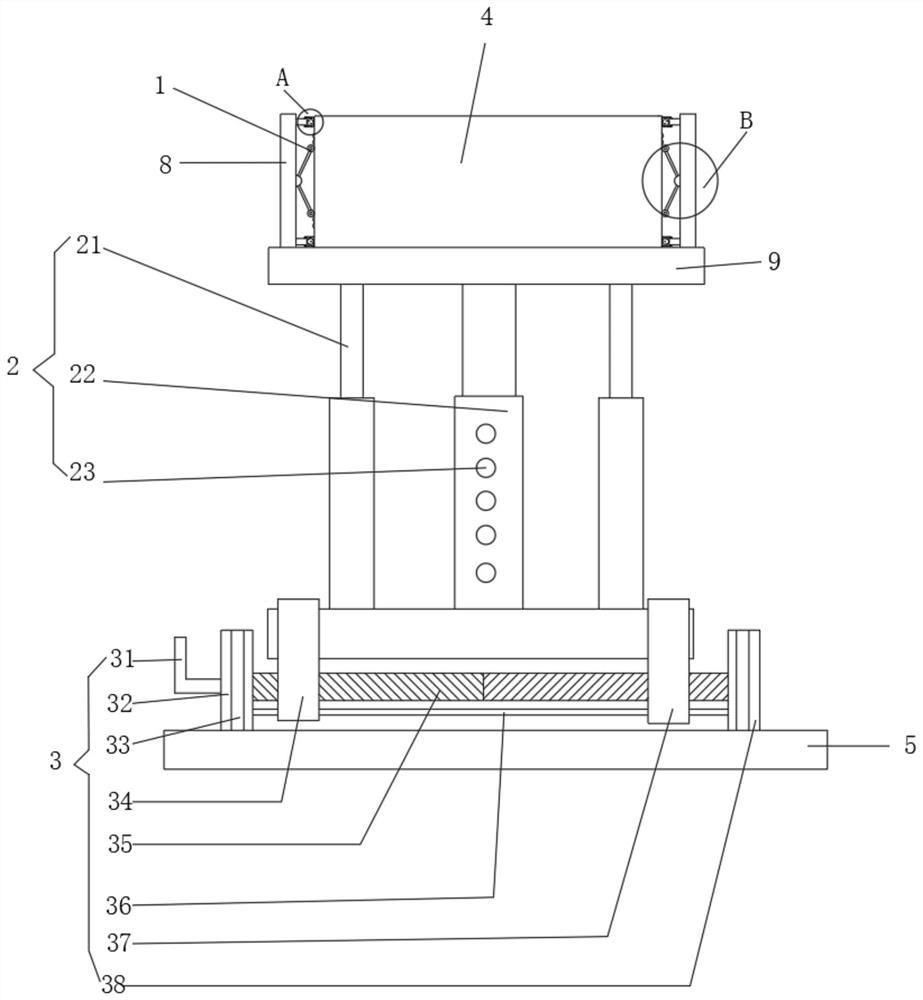

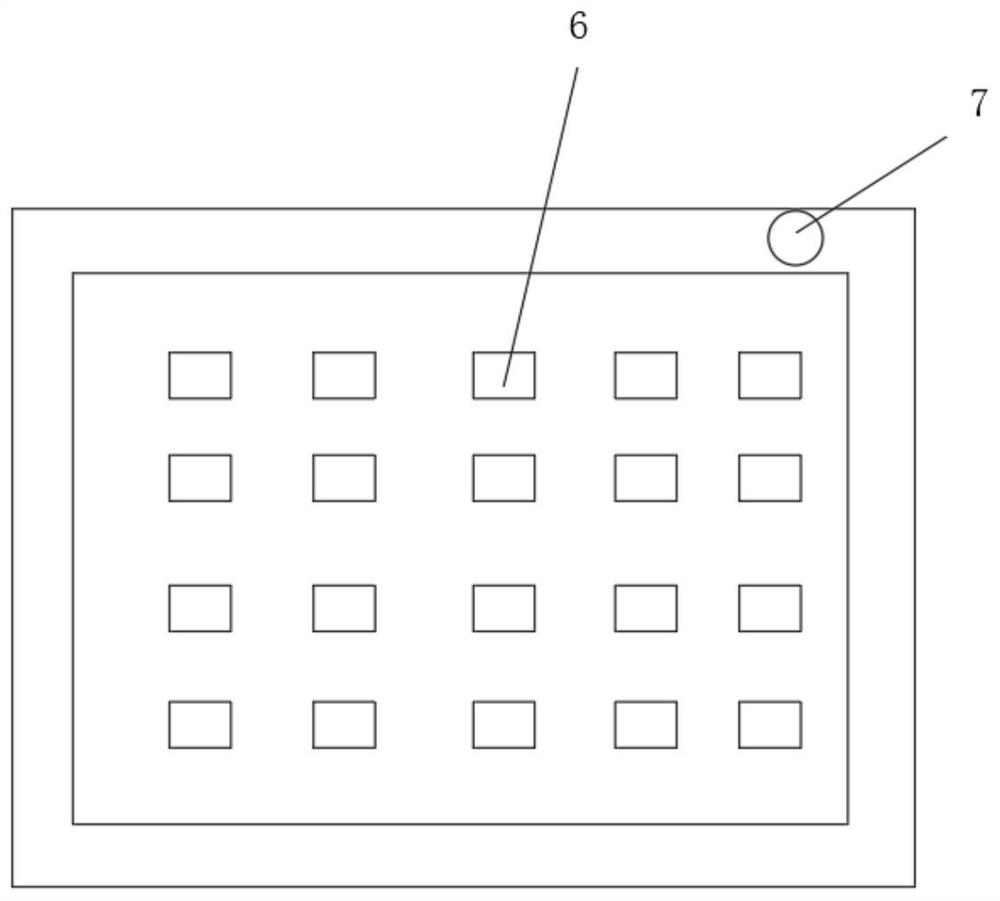

[0032] see Figure 1-6, a remotely operable control device for substation maintenance, comprising a base 5, a mounting mechanism 3 is fixedly installed on the top of the base 5, a lifting mechanism 2 is fixedly mounted on the base 5 through the mounting mechanism 3, and a top block 9 is fixedly mounted on the top of the lifting mechanism 2 , a protective mechanism 1 is fixedly installed on both sides of the top of the top block 9, a controller main body 4 is installed in the middle of the top of the top block 9, a side plate 8 is fixedly installed on the outer side of the protective mechanism 1, and a button 6 is arranged on the top of the controller main body 4. The top of the outer wall of the main body 4 is provided with a signal transmitter 7;

[0033] The protection mechanism 1 includes a connecting rod 16, the connecting rod 16 is hinged to the inner side of the side plate 8, a buffer wheel 15 is installed in a section of the connecting rod 16 to rotate, a buffer sleeve ...

Embodiment 2

[0036] see Figure 1-6 , and on the basis of the first embodiment, it is further obtained that the lifting mechanism 2 includes an adjusting rod 22, the adjusting rod 22 is fixedly installed on the top of the middle of the base 5, and the front of the adjusting rod 22 is provided with a card slot 23, and the adjusting rod 22 is clamped through the card slot 23. There is a buckle 24, a bar 26 is fixedly installed on the back of the buckle 24, a spring 27 is fixedly installed on the back of the bar 26, a box 25 is sleeved on the outer surface of the spring 27, and electric telescopic rods are fixedly installed on both sides of the adjustment rod 22 through the base 5 twenty one.

[0037] Further, a top block 9 is fixedly installed on the top of the electric telescopic rod 21, and a top block 9 is fixedly installed on the top of the adjusting rod 22. The box 25 is provided with a slot corresponding to the position of the buckle 24, and the box 25 is slidably installed with the bu...

Embodiment 3

[0039] see Figure 1-6 , and on the basis of Embodiment 1 and Embodiment 2, it is further obtained that the installation mechanism 3 includes a first installation plate 32, the first installation plate 32 is fixedly installed on the left side of the top of the base 5, and a handle is fixedly installed on the left side of the first installation plate 32 31. A two-way threaded rod 35 is fixedly installed on the right side of the first mounting plate 32, a first threaded sleeve 34 is installed on the left outer thread of the two-way threaded rod 35, and a sliding rod 36 is slidably installed inside the first threaded sleeve 34. The first installation plate A panel 33 is fixedly mounted on the front of 32 , a second threaded sleeve 37 is threadedly mounted on the right outer surface of the bidirectional threaded rod 35 , and a second mounting plate 38 is fixedly mounted on the other side of the bidirectional threaded rod 35 away from the first mounting plate 32 .

[0040] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com