Flame-proof structure at cable joint of telecommunication equipment

A kind of cable joint, equipment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

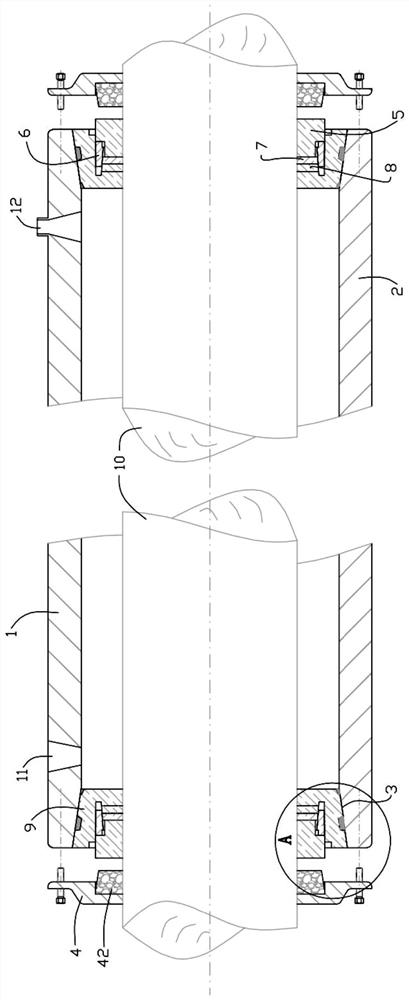

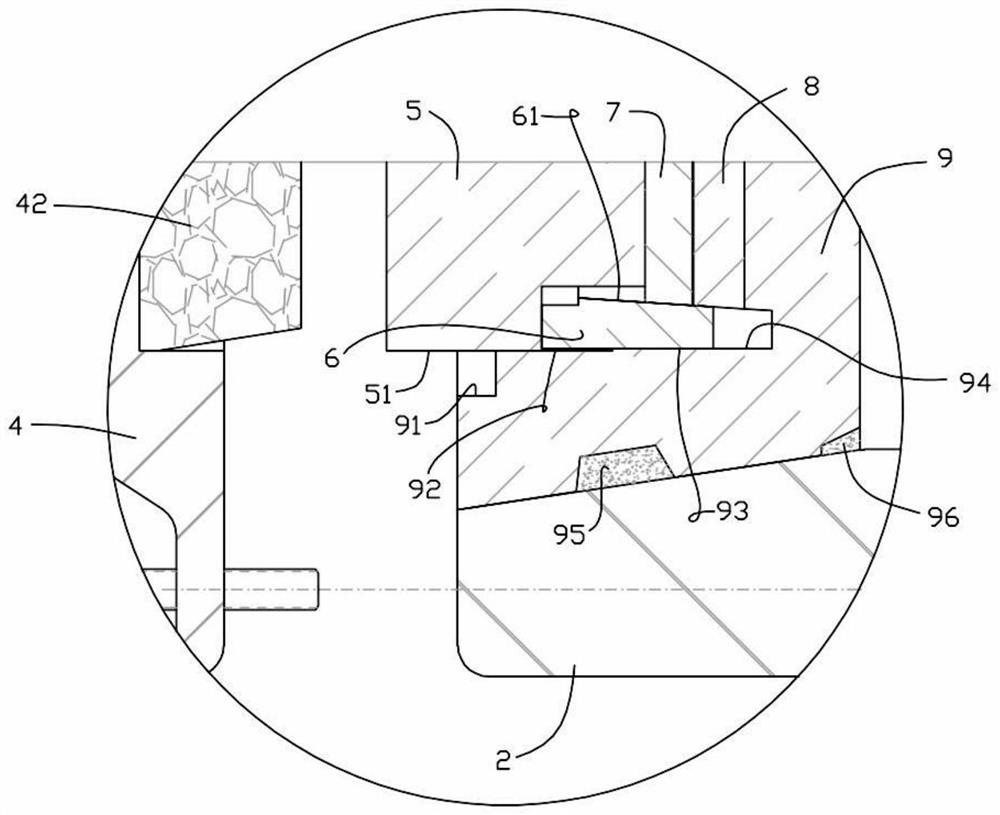

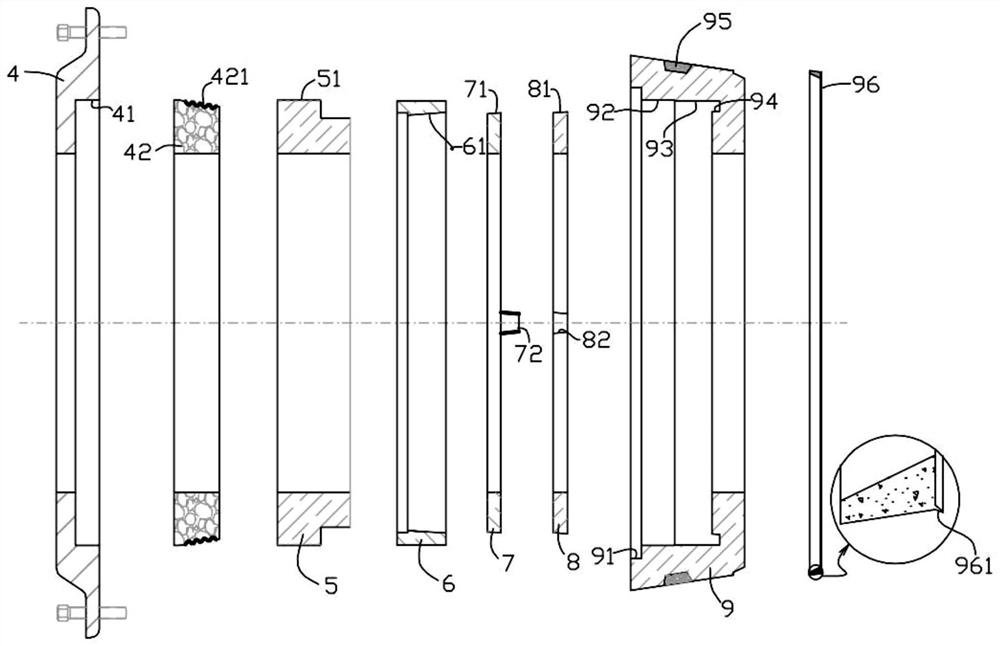

[0035] like Figure 1 to Figure 4 The flame-proof structure at the cable joint of telecommunication equipment as shown includes an upper half-pipe body 1 and a lower half-pipe body 2 that can be fastened to form a pipe body, and a cover plate 4 that is respectively arranged at both ends of the buckled pipe body. , a pressure ring 5 , a plug ring 6 , the first elastic ring 7 and the second elastic ring 8 used in pairs, and two sets of component units of the cone ring 9 .

[0036] Conical countersunk holes 3 are respectively formed at both ends of the pipe body formed by the upper half-pipe body 1 and the lower half-pipe body 2, and the two sets of component units are correspondingly matched to the two conical holes. Counterbore 3.

[0037] The cable 10 is matched with the shaft holes formed on the cover plate 4 , the pressure ring 5 , the plug ring 6 , the first elastic ring 7 , the second elastic ring 8 and the cone ring 9 respectively . That is, the cable 10 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com