Hazardous waste pretreatment system based on nitrogen protection

A hazardous waste and nitrogen protection technology, which is applied in grain processing, solid separation, chemical instruments and methods, etc., can solve problems such as low crushing efficiency, uneven crushing, and difficult incineration, so as to improve shaking stability and crushing efficiency , Improve the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

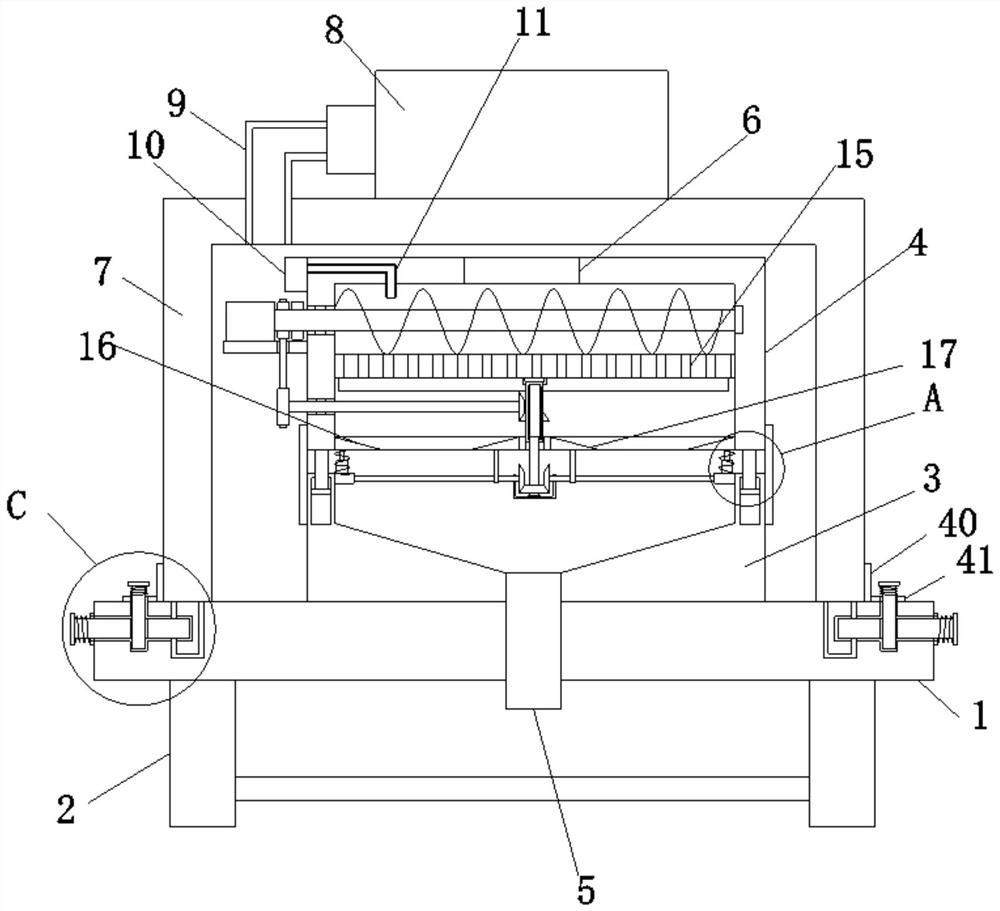

[0032] Example one, by Figure 1 to Figure 6Given, the present invention includes a base 1, the bottom end of the base 1 is symmetrically provided with a support leg 2, the top of the base 1 is provided with a pretreatment tank body 1 3, and a pretreatment tank body 2 4 is provided above the pretreatment tank body 1 3 , the pretreatment tank body 1 3 and the pretreatment tank body 2 4 are connected by a connecting group, the bottom end of the pretreatment tank body 1 3 is provided with an outlet pipe 5 that penetrates below the base 1, and the top end of the pretreatment tank body 2 4 is provided A feeding port 6 is opened, the top of the base 1 is provided with a sealing cover 7 sleeved on the outside of the pretreatment tank body 1 3 and the pretreatment tank body two 4, and the top of the base 1 is provided with a sealing cover 7 sleeved on the outer bottom end of the cover 7. The sleeve seat 40, the bottom end of the sleeve seat 40 is provided with a pressure plate 41. The...

Embodiment 2

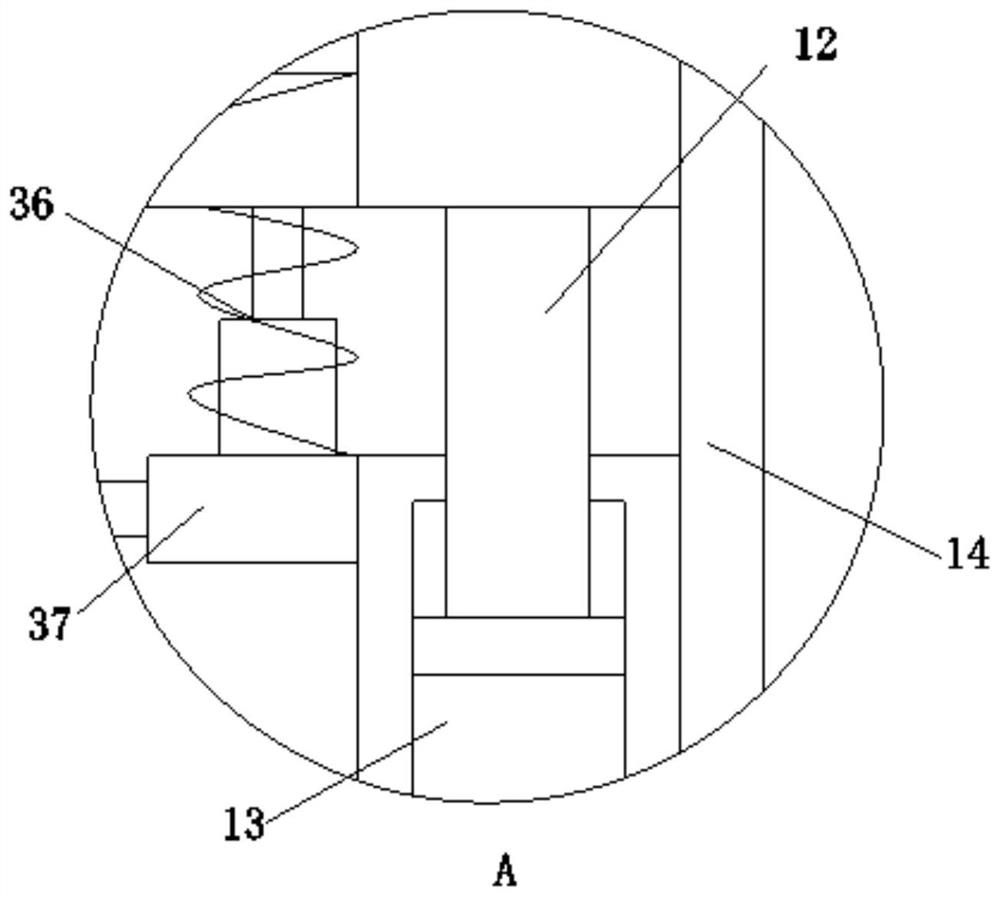

[0035] Embodiment 2, on the basis of Embodiment 1, by figure 1 and image 3 Given, the connecting group includes a stabilizer bar 12, a stabilization groove 13, a sleeve plate 14 and a connecting piece, the bottom end of the pretreatment tank body 24 is symmetrically provided with a stabilizer bar 12, and the top end of the pretreatment tank body 13 is provided with a stabilizer bar. 12 The stabilizing groove 13 for sliding connection, the bottom end of the outer wall of the pretreatment tank 24 is provided with a sleeve plate 14 sleeved on the outside of the pretreatment tank The connector is connected. The connector includes an elastic telescopic rod 36 and a fixed seat 37. The top of the inner wall of the pretreatment tank 24 is symmetrically provided with a fixed seat 37, and the top of the fixed seat 37 is provided with an elastic telescopic rod connected to the inner bottom end of the bottom plate 16. 36;

[0036] Through the action of the acceleration mechanism, the b...

Embodiment 3

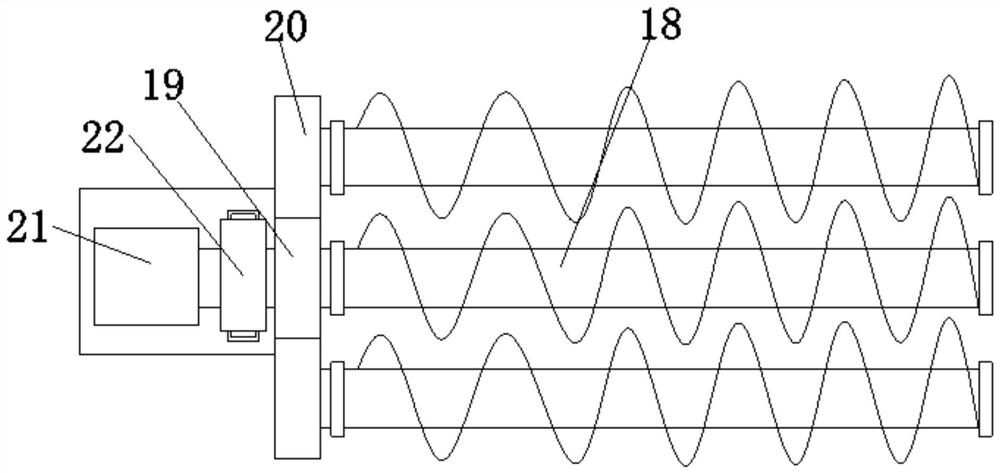

[0037] Embodiment 3, on the basis of Embodiment 1, by figure 1 , Figure 4 and Figure 5 Given, the acceleration mechanism includes a scraper group, a transmission part 1, a transmission part 2 and a shaking group, and the scraper group includes a rotating drum 23, a bearing seat 24, a scraper 25 and a bevel gear 1 26, the middle of the bottom end of the filter plate 15 A rotating cylinder 23 is provided at the position. The rotating cylinder 23 is connected with the filter plate 15 through the bearing seat 24. The outer top of the rotating cylinder 23 is symmetrically provided with a scraper 25 which is slidingly connected with the bottom end of the filter plate 15. Bevel gear 1 26, bevel gear 1 26 is connected with transmission member 1, a shaking group is arranged under the rotating cylinder 23, and the shaking group and the rotating cylinder 23 are connected through transmission member 2. Transmission member 1 includes a pulley 22, a transmission shaft 27. The second bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com