Transportation treatment device for bungalow building waste

A construction waste and processing device technology, applied in construction waste recycling, grain processing, recycling technology and other directions, can solve the problems of affecting crushing efficiency, uneven distribution of construction waste, construction personnel and environmental impact, etc., and achieve the effect of alleviating accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

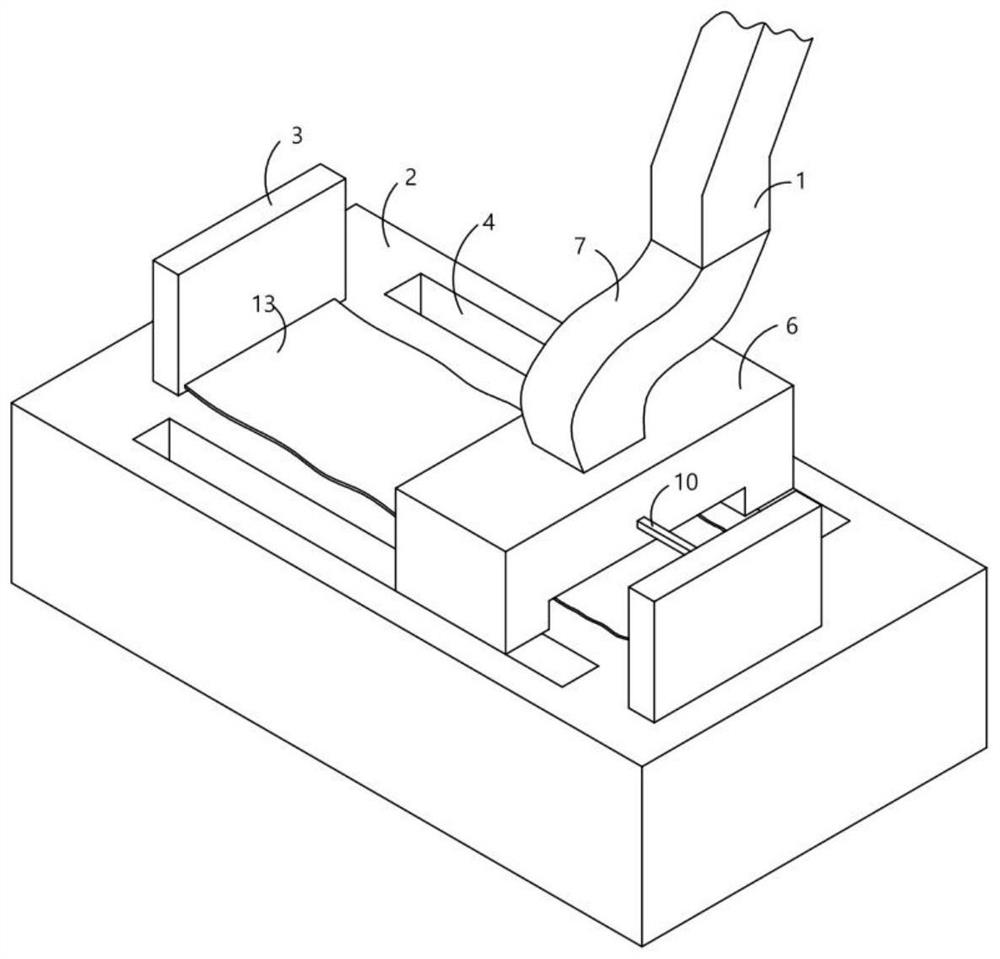

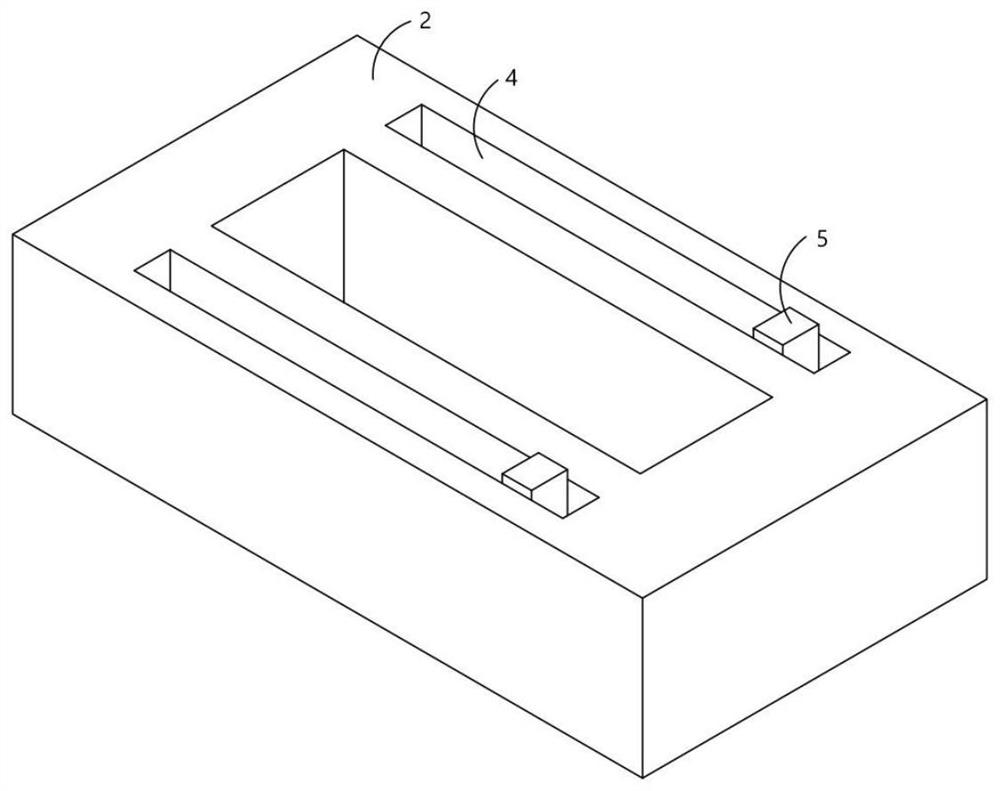

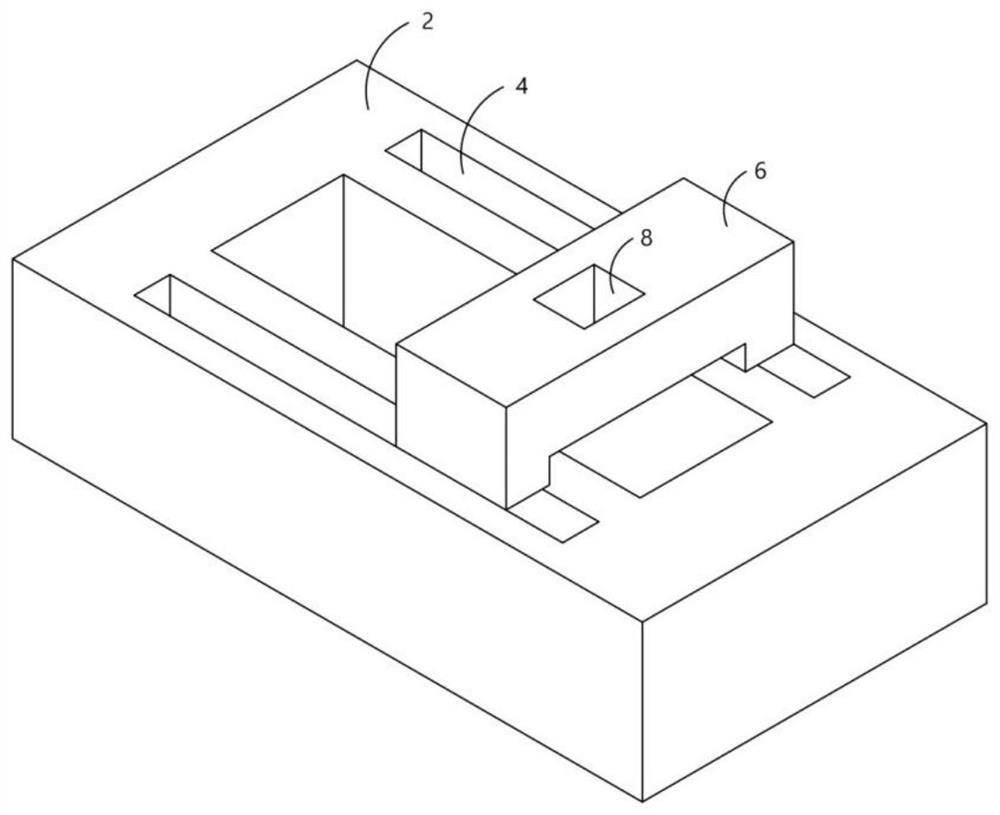

[0044] A transportation and processing device for bungalow construction waste, including a conveying pipe 1 and a crushing box 2. The conveying pipe 1 in this embodiment has a certain inclination angle. When the operator puts the waste into the conveying pipe Under the action of the conveying pipe 1, it slides down to the inside of the distribution box 6. The crushing box 2 is provided with rotating crushing gear teeth to crush the waste. The opening ends of the crushing box 2 are fixed with fixed plates 3. In this embodiment, the fixed plate 3 is fixed. The plate 3 is arranged at both ends of the opening of the crushing box 2, and the surface of the crushing box 2 is provided with a track groove 4, and a track block 5 is movably arranged inside the track groove 4, and the track block 5 is movably clamped inside the track groove 4. 5 can move left and right along the track groove 4;

[0045] The track block 5 is fixedly connected with a distribution box 6 for evenly distributi...

Embodiment 2

[0048] In this embodiment, it is considered that the waste material falls into the crushing box 2 through the distribution cavity 9. In this embodiment, a vibration device is arranged inside the distribution cavity 9, so that the waste material entering the distribution cavity 9 is under the action of the vibration device. , evenly distributed in the distribution cavity 9, so that under the action of the reciprocating distribution box 6, the waste can be further evenly distributed into the crushing box 2. The vibrating device includes a rotating set inside the distribution cavity 9. The vibration plate 14, and the vibration plate 14 and the side wall of the distribution cavity 9 are fixedly connected with a first elastic block 15. Under the support of the first elastic block 15, the vibration plate 14 is obliquely arranged inside the distribution cavity 9. The vibration plate 14 is rotatably arranged inside the distribution cavity 9, and under the action of the first elastic bl...

Embodiment 3

[0050] On the basis of the second embodiment, the structure of the trigger device in the second embodiment is disclosed. The trigger device includes a switch 28 that is fixedly arranged inside the distribution cavity 9 and is electrically connected to the electromagnet 20 . The switch 28 in this embodiment is: Press-contact switch, the switch 28 and the electromagnet 20 are connected in series by a wire and a power supply. When the waste material accumulates in the distribution chamber 9, the pressure of the accumulated waste material on the vibration plate 14 increases, so that the inclination angle of the vibration plate 14 changes. Large, thus driving the elastic rod 29 to squeeze the switch 28 . At this time, the electromagnet 20 is energized and has magnetism, and the vibration plate 14 is fixedly connected with the elastic rod 29 in active contact with the switch 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com