Automatic fruit arranging and conveying equipment

A technology for automatically arranging and conveying equipment, applied in sorting and other directions, can solve the problems of easy blockage, large labor, low precision, etc., and achieve the effects of high practicability, improved detection accuracy, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

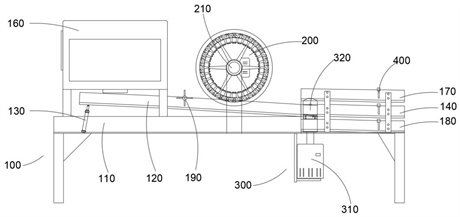

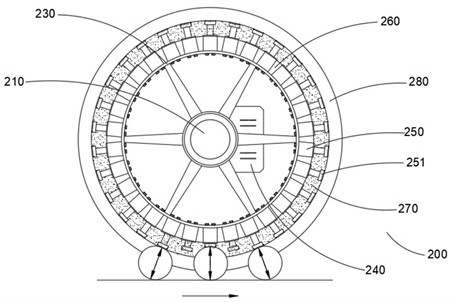

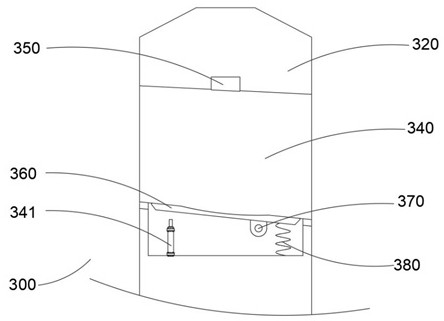

[0030] combine Figure 1-Figure 4 As shown, the present invention provides a fruit automatic arrangement and conveying device, including: a conveying mechanism 100, a detection mechanism 200 and a sieving and arrangement mechanism 300;

[0031] The conveying mechanism 100 includes a workbench 110 , a blanking plate 120 hinged on the workbench 110 , an adjusting cylinder 130 connected between the movable end of the blanking plate 120 and the workbench 110 , an adjustment cylinder 130 installed on the workbench 110 and connected to the workbench 110 . A conveying plate 140 connected to the blanking plate 120 , a separating plate 150 disposed in the blanking plate 120 and the conveying plate 1 140 , a silo 160 installed on the work table 110 and located above the adjusting cylinder 130 , and installed on the work table 110 And the second conveying plate 170, the third conveying plate 180 and the unloading assembly 190 installed on the unloading plate 120 are located on the upper ...

Embodiment 2

[0041] combine figure 1 and Figure 4 As shown, on the basis of the first embodiment, the first conveying plate 140, the second conveying plate 170 and the third conveying plate 180 are respectively equipped with an arrangement assembly 400, and the arrangement assembly 400 includes a torsion spring shaft installed on the first conveying plate 140 410 , a baffle plate 420 connected to the bottom of the torsion spring shaft 410 , and a servo motor three 430 connected to one end of the torsion spring shaft 410 .

[0042] Specifically, the arrangement assembly 400 can block the fruit conveyed on the first conveying plate 140, the second conveying plate 170 and the third conveying plate 180. When the fruit is piled up to a certain extent, the baffle plate 420 will be pushed to discharge the fruit, and the fruit can also be actively discharged. Drive the discharge to arrange and transport the fruit.

[0043] The working principle and use process of the present invention: first, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com