Cement mortar processing method

A processing method and cement mortar technology, which are applied in cement mixing devices, chemical instruments and methods, climate sustainability, etc., can solve problems such as the inability to effectively improve the efficiency of brick-bonded mortar molding, and prevent accumulation and deposition. Promotes blending, effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

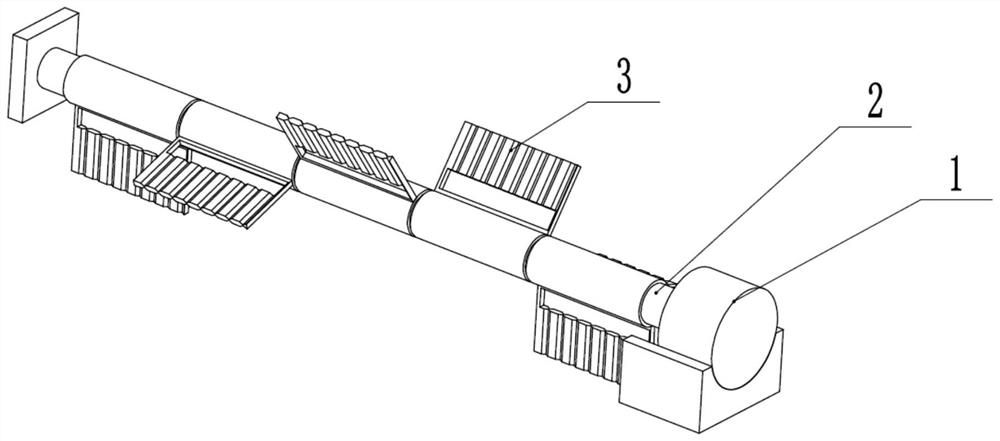

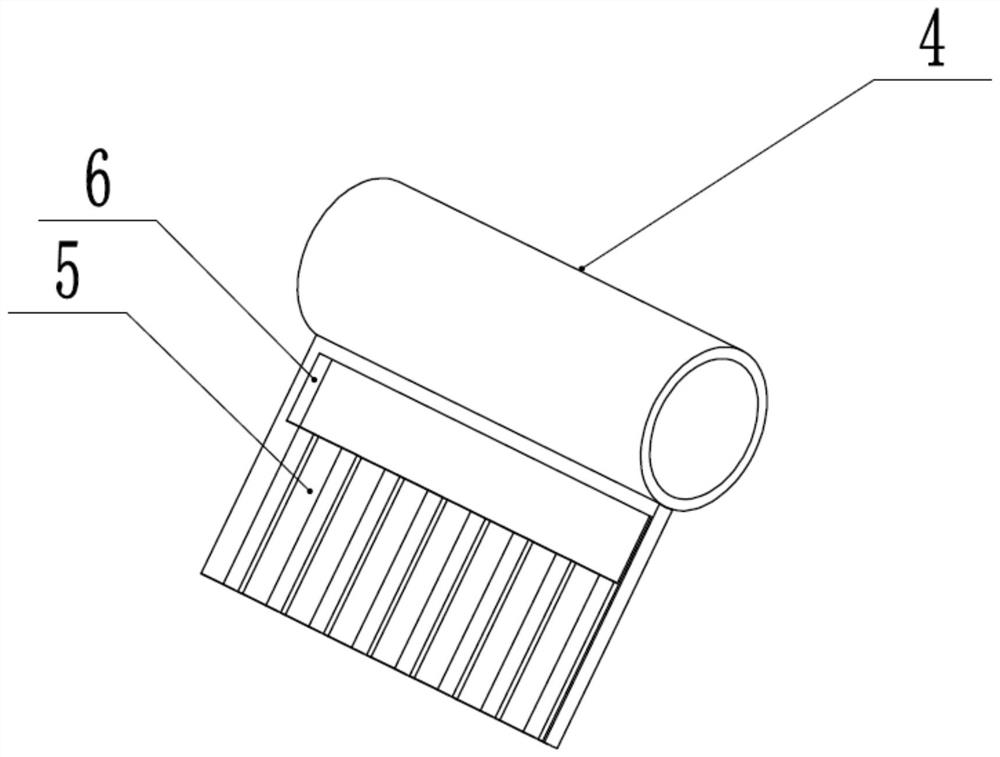

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] As shown in the embodiment shown here,

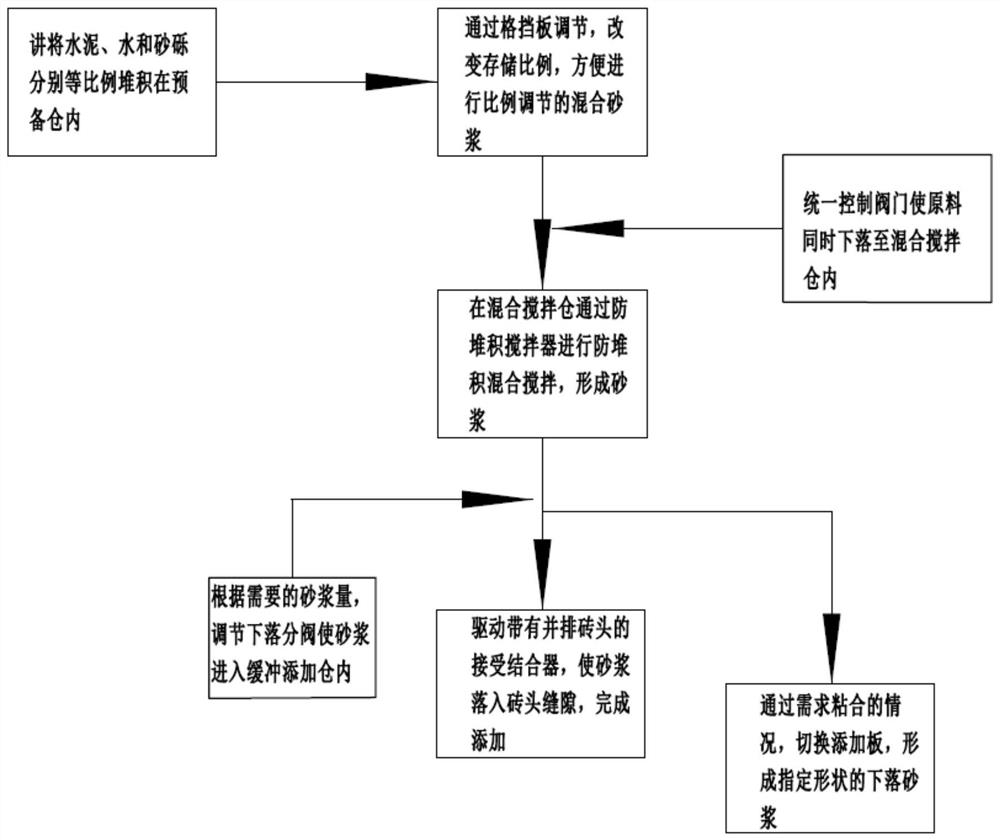

[0030] By adding the prepared cement, water and gravel into the preliminary bin, adjusting the proportion parameters of cement and gravel based on the proportion of water through the setting of the sliding partition, and performing preliminary addition to realize the adjustment of the mixing ratio of the mortar; Mix it and drop it into the mixing chamber. Through the anti-sedimentation stirring method, while promoting the mixing of the mortar, it prevents accumulation and deposition, and avoids the mixing of gravel and cement inside the mortar, resulting in uneven mixing; at the same time, through adjustment and control, part of the mortar falls into the buffer bin. , to achieve effective use while avoiding the accumulation of too much mortar for backup to prevent sedimentation; at the same time, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com