Crack treatment equipment based on asphalt concrete pavement reflection

A technology of asphalt concrete and processing equipment, which is applied in the field of crack treatment, which can solve the problems of inconvenient removal of stones, inconvenient collection of stones and blockages, lack of stones, etc., and achieve the effect of avoiding cracking again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

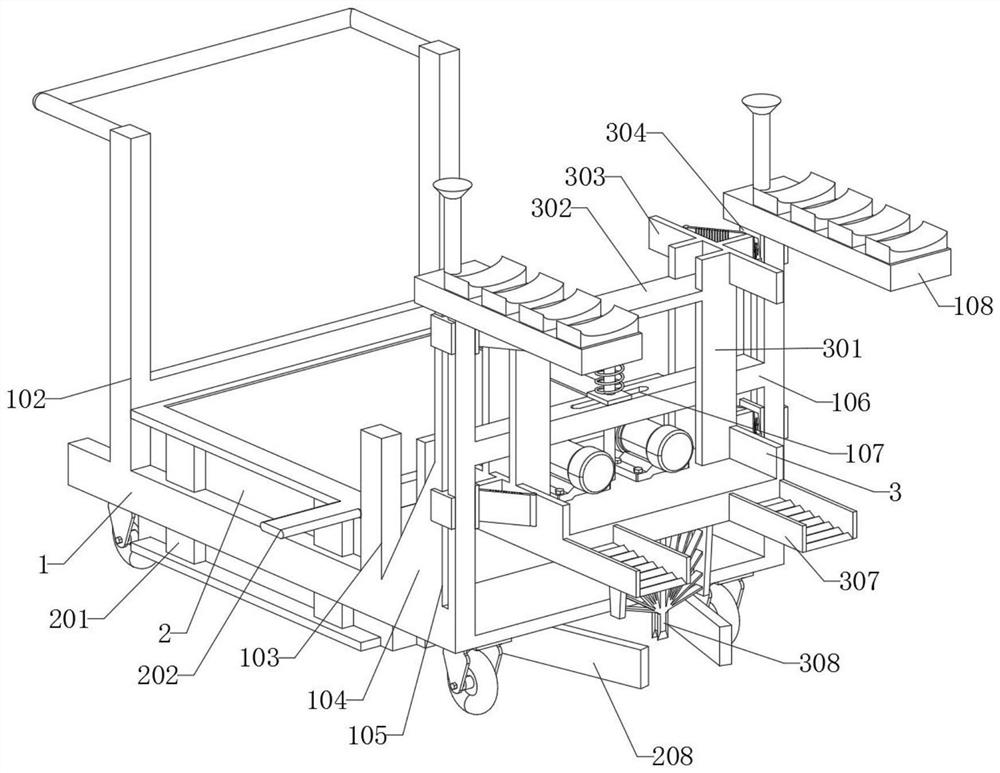

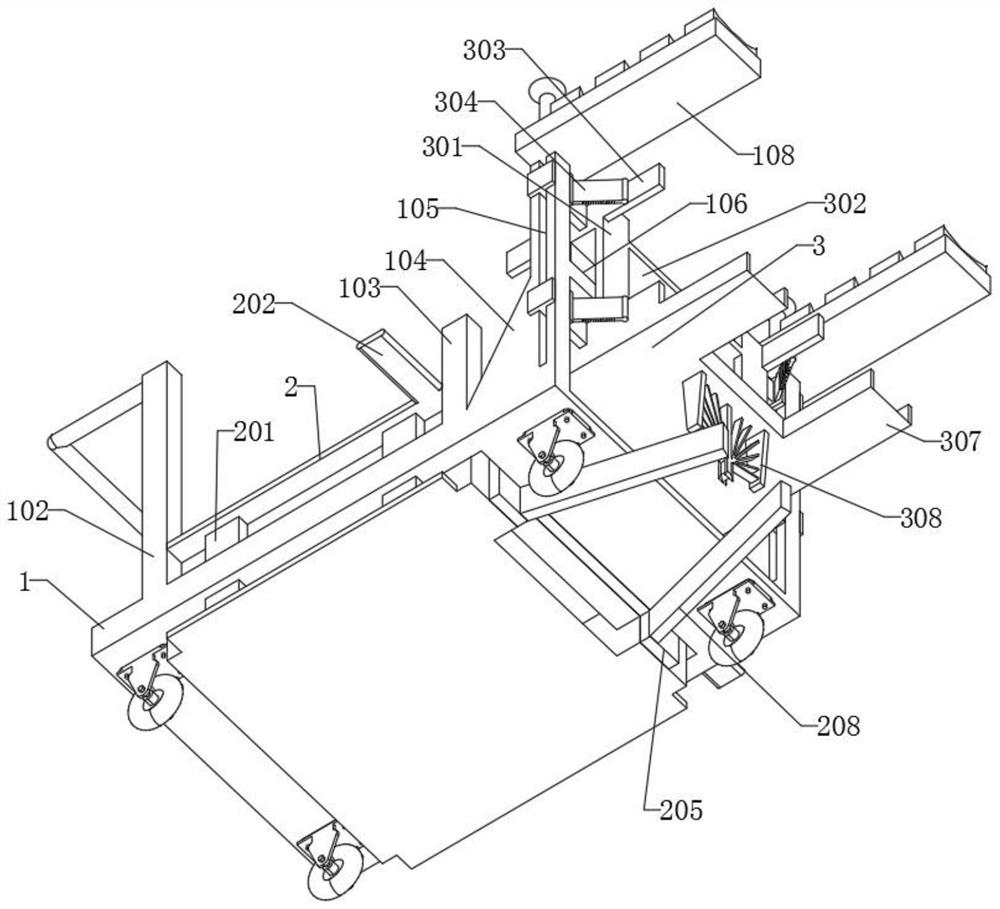

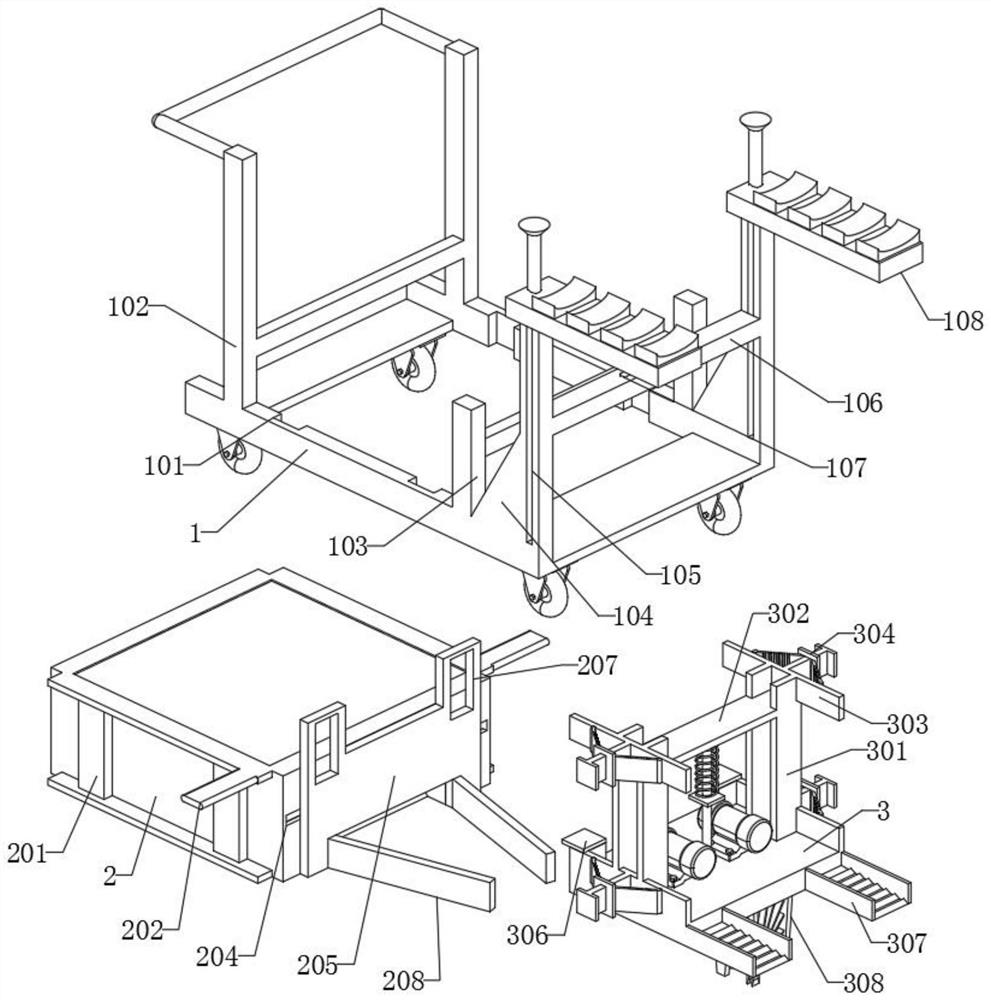

[0030] Example: please refer to Figure 1 to Figure 8 :

[0031]The invention proposes a crack treatment equipment based on the reflection of asphalt concrete pavement, including: a main body 1; the main body 1 is a rectangular frame structure, so that the collector 2 can be installed in the interior for mobile use, and when the main body 1 moves, the collector 2 can rise , out of contact with the ground, the bottom of the main body 1 is provided with a moving wheel, so that the main body 1 can be used in a convenient moving position. The top of the 104 is provided with a control member 108, the control member 108 is of a rectangular structure, and a handle is provided above the front end of the control member 108, which can be easily held by the hand. The inside of the part 108 is provided with evenly arranged contact plates, the contact plate is made of rubber, and the top of the contact plate is an arc structure, which is used to contact the bottom of the user's arm, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com