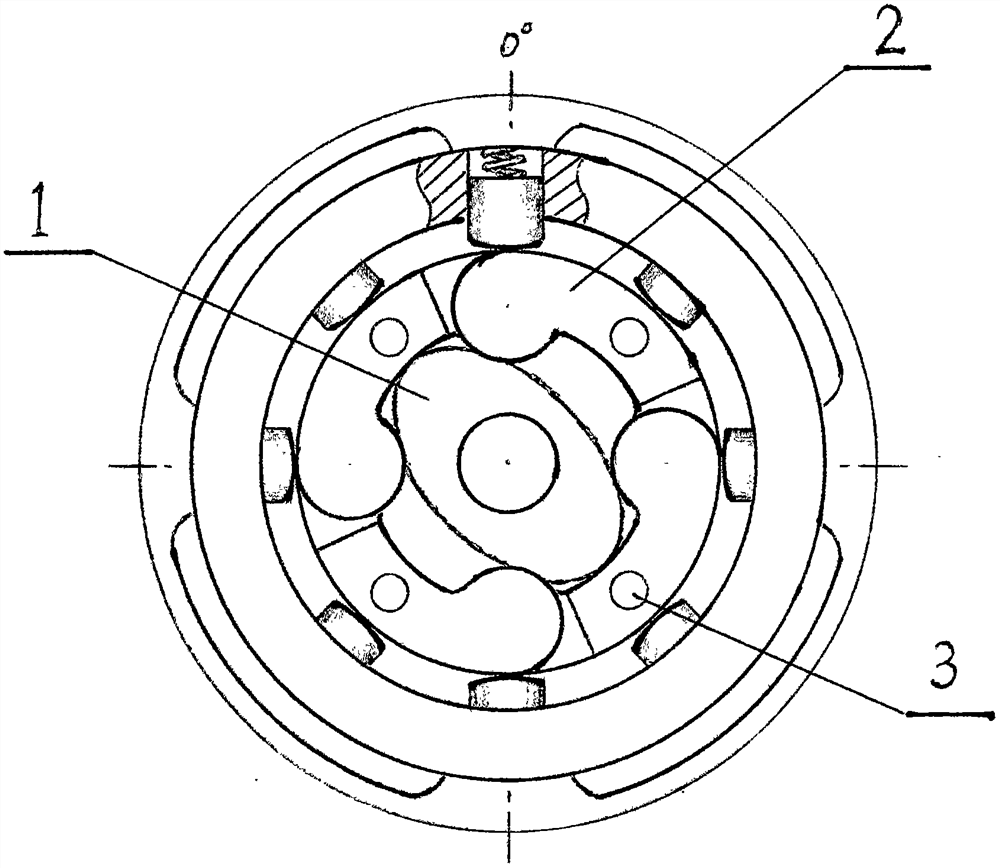

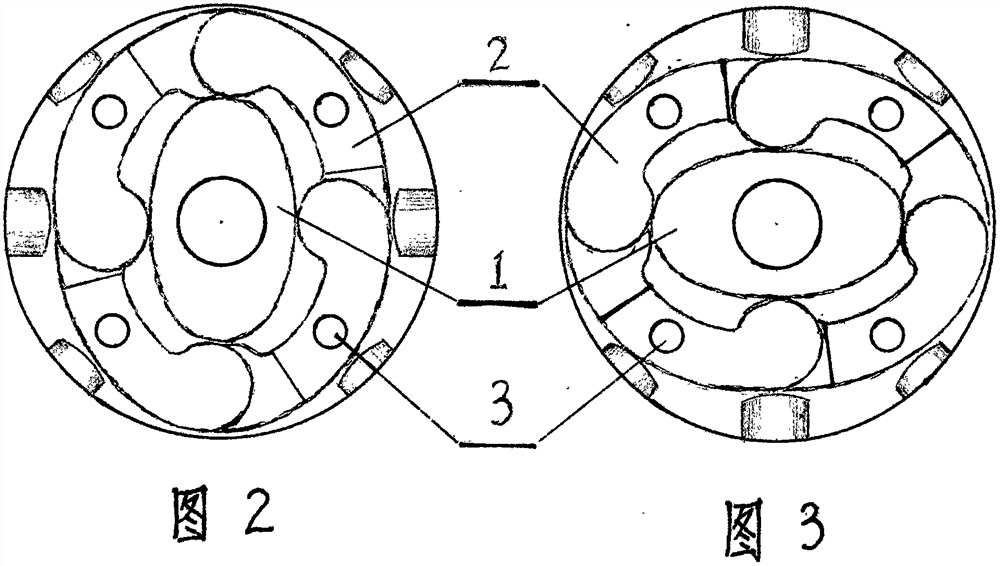

Double-acting variable technology of liquid-gas equipment

A double-acting, equipped technology, applied in mechanical equipment, climate sustainability, transmission control, etc., can solve problems such as affecting dynamic seals, insignificant hazards, and wear of moving parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The liquid-gas double-acting variable technology was one of the applicant's ideas many years ago. At that time, I thought that there was no harvester suitable for hilly and mountainous areas, so a simple and lightweight harvester was envisaged. to adapt to various complex terrains. Later, Japan's small harvesters appeared in large numbers in hilly areas. They were very advanced in performance, could adapt to various terrains, and had high efficiency and low fees. The inventor completely gave up and forgot about the simple harvester. However, at the end of November 2020, the applicant was invited to Ningbo to participate in the "Second Hydraulic Pneumatic Digital Intelligence Enterprise Forum", only to know that the basic components of hydraulic pressure have been stagnant for many years, and some hydraulic enterprises that want to achieve breakthroughs in basic components, Basically, they belong to the blind man who has not figured out the direction; and the simple tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com