Heating and separating device for ground gathering and transportation of shale gas and using method of heating and separating device

A separation device and shale gas technology, applied in separation methods, transportation and packaging, separation of dispersed particles, etc., can solve problems such as time-consuming and labor-intensive, lower work efficiency, and failure to meet use requirements, so as to reduce waste and improve work efficiency Effect

Pending Publication Date: 2022-08-05

SENUO TECH CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The heating separation device disclosed in the above-mentioned patent still has some deficiencies. Its oil inlet pipe lacks the function of filtering and collecting the particulate impurities in the oil and gas, so that a large amount of impurities can easily enter the separation tank. Cooperate with the filter to filter, but this kind of filter has the disadvantage of being inconvenient to intelligently and automatically clean and dredge the filter and discharge slag when clogging occurs. It requires personnel to stop the machine regularly for manual disassembly and cleaning, and the method of stopping the machine for disassembly and cleaning is time-consuming laborious, and need to occupy a long shutdown waiting time, reduce work efficiency), can not meet the needs of use, combined with the above phenomenon to improve the deficiencies of the existing technology, so we proposed a shale gas ground gathering and transportation heating separation Device and method of use thereof for solving the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

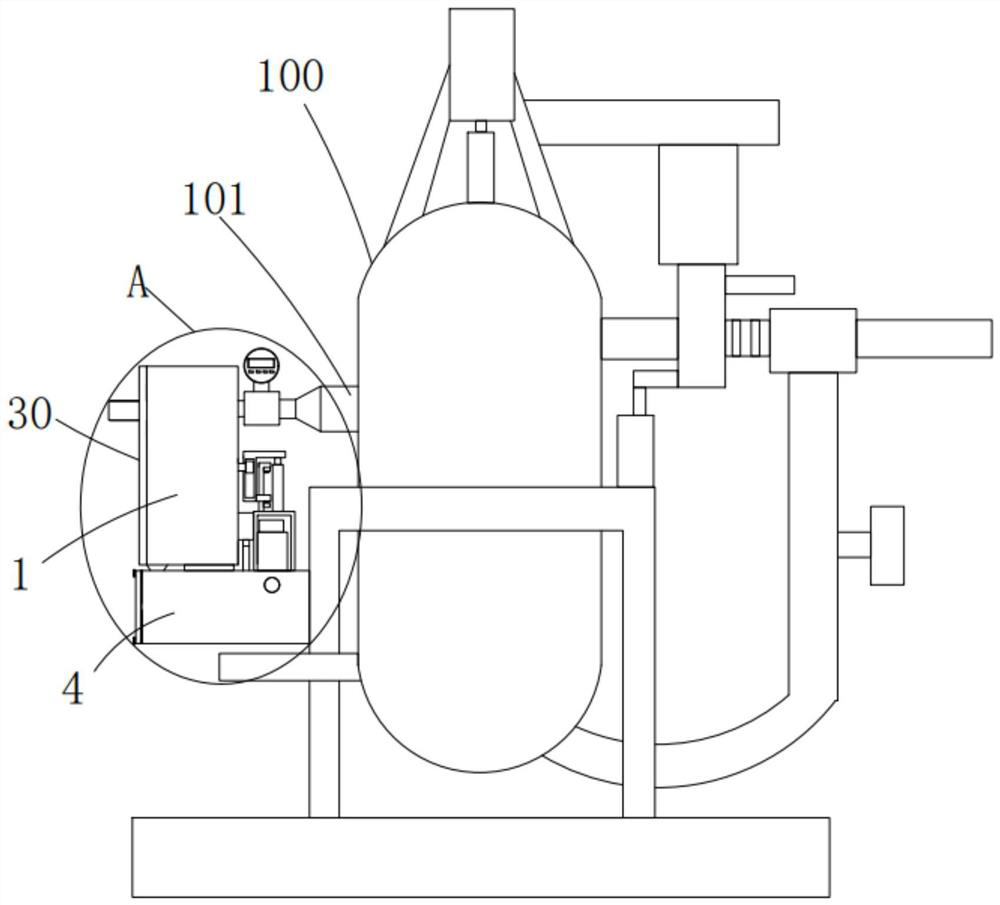

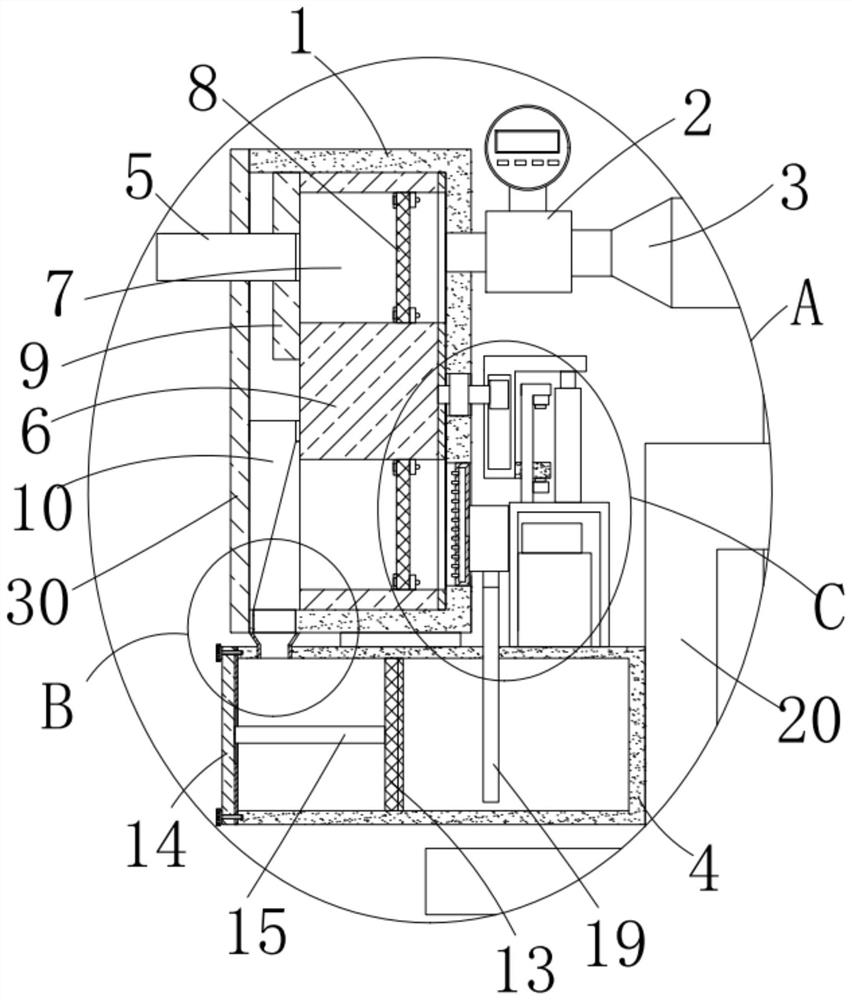

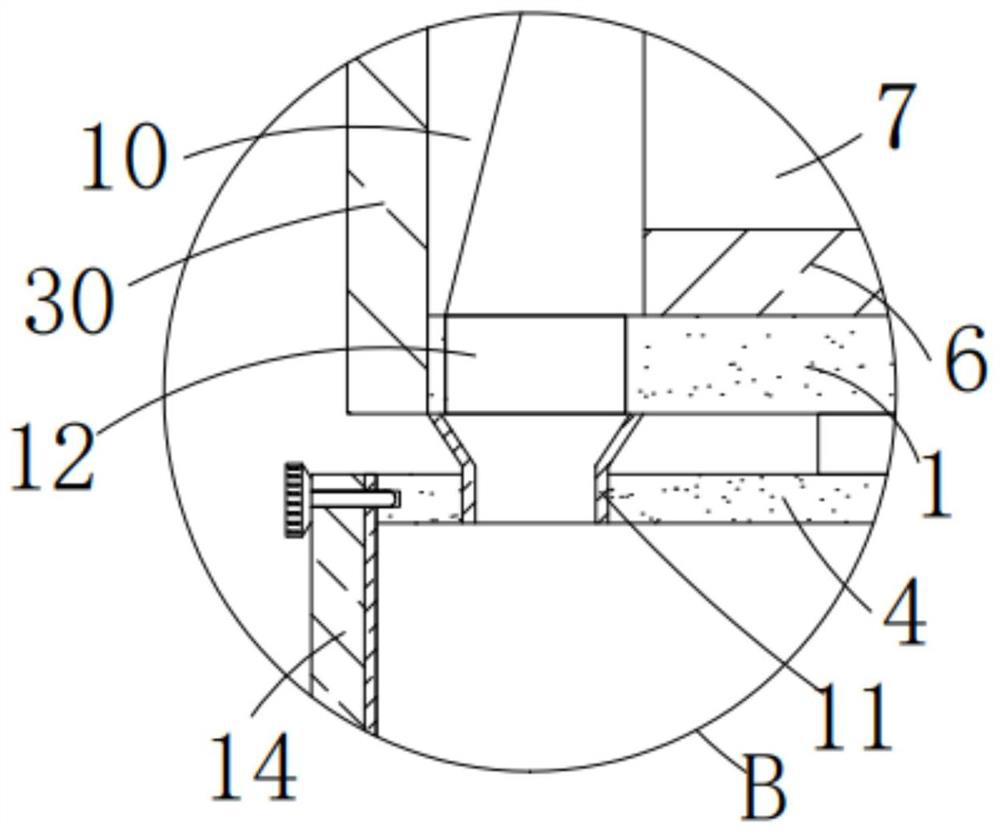

[0031] refer to Figure 1-4 In this embodiment, a heating and separation device for shale gas ground gathering and transportation is proposed, which includes a separation tank 100 and an inlet pipe 101 connected to and fixed on the left side of the separation tank 100. The left end of the inlet pipe 101 is provided with an intelligent self-cleaning residue filter mechanism ;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a heating and separating device for ground gathering and transportation of shale gas and a using method thereof.The heating and separating device comprises a heating and separating device body, the heating and separating device body comprises a separating tank and an inlet pipe which communicates with and is fixed to the left side of the separating tank, and an intelligent filter residue self-cleaning mechanism is arranged at the left end of the inlet pipe; the intelligent filter residue self-cleaning mechanism comprises a round box arranged on the left side of the inlet pipe, and the left side of the round box is provided with an opening and is fixedly connected with a cover plate. Particle impurities in shale oil and gas can be conveniently filtered and collected, a large amount of particle impurities are prevented from entering the separation tank, and the two filter screens can be intelligently and automatically cleaned and dredged and can be automatically discharged in a manner that the two filter screens are intelligently and automatically subjected to alternate filtering and backflushing cleaning when blockage occurs; the device is simple in structure and convenient to use, manual dismounting and cleaning by personnel during shutdown in the using process are not needed, the working efficiency is improved, water used for flushing can be conveniently filtered and recycled, and the water waste phenomenon is reduced.

Description

technical field [0001] The invention relates to the technical field of heating separation equipment, in particular to a heating separation device for ground gathering and transportation of shale gas and a method for using the same. Background technique [0002] In the field of oil and gas surface gathering and transportation, shale gas needs to use heating separation devices to separate shale oil and gas when shale gas is gathering and transporting on the ground. Shale gas occurs in unconventional organic-rich shale reservoir rocks The heating and separation method of natural gas is the same as the separation method of oil and gas gathering and transportation in the oil field, and a heating separation device is required for heating and separation; for the heating and separation of oil and gas, in the prior art, Application No. 202020034017.X discloses an oil field gathering device. The heating separation device for transportation comprises a base, the base is fixedly connect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D46/12B01D46/90B01D46/72B01D46/00C10L3/10

CPCB01D46/12B01D46/90B01D46/72B01D46/0086C10L3/101

Inventor 孙莉莉柳润泽梁文豪于学敏黄金禄张楠周子鹏尤晓卉

Owner SENUO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com