Mixing system and process for waterproof coating production

A technology for mixing systems and waterproof coatings, which is applied in mixers, fluid mixers, natural rubber coatings, etc., and can solve problems such as inconvenient deployment, high accuracy requirements for proportioning ingredients, and inability to filter solid particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

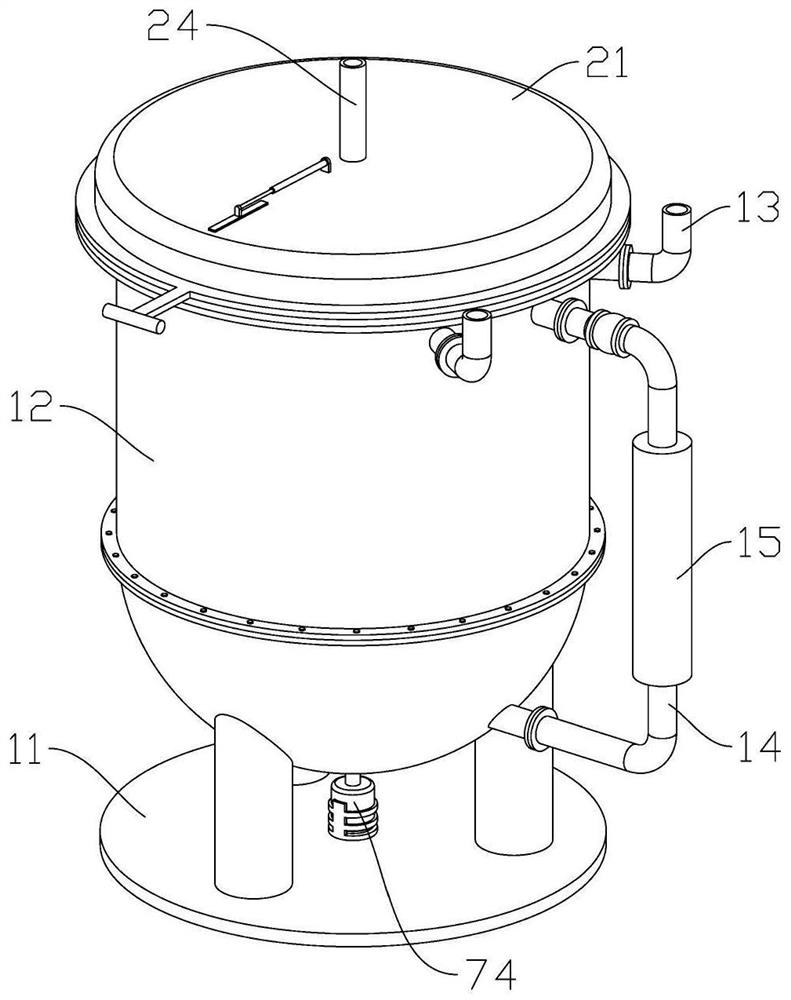

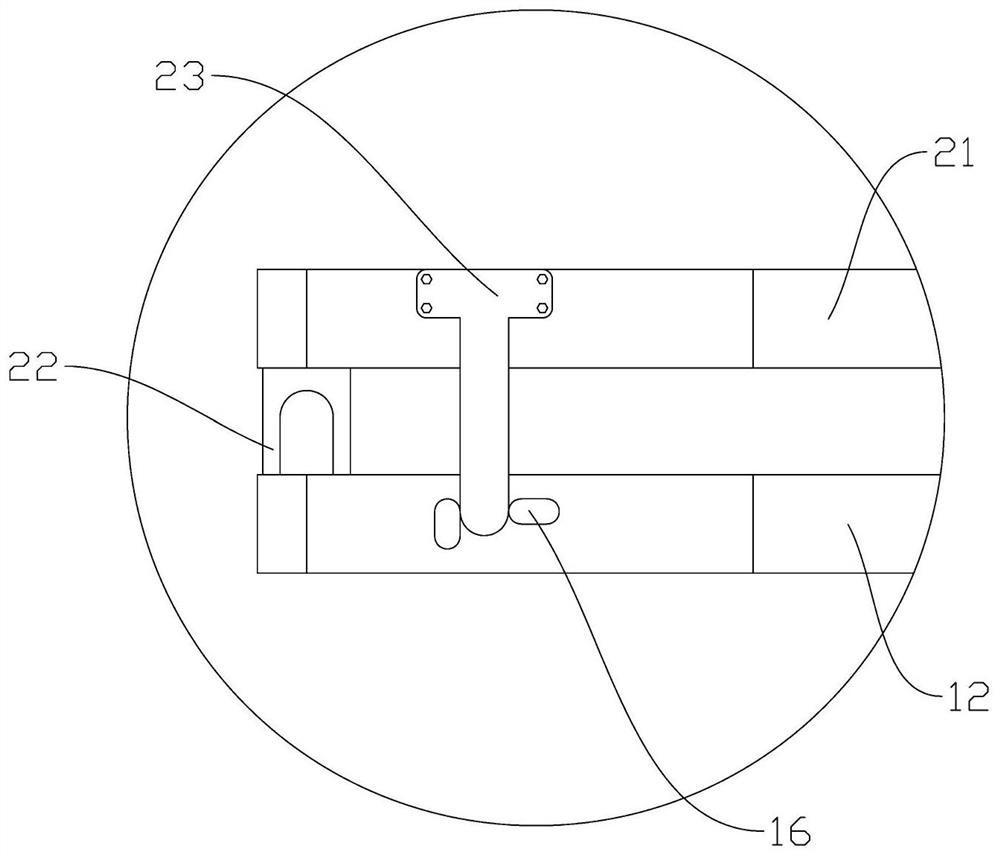

[0031] With reference to the accompanying drawings in the embodiments of the present invention, a mixing system and process for producing a waterproof coating provided by the present invention will be described in detail.

[0032] To illustrate the embodiments of the present invention, see figure 2 , Figure 4-6 :

[0033] A mixing system for waterproof paint production, comprising a base 11 and a mixing container 12 mounted on the base 11, the mixing container 12 is provided with a circulation conveying pipe 14 and a plurality of filling pipes 13, and the circulation conveying pipe 14 is provided with Filter cartridge 15, a cover plate 21 is installed on the mixing container 12, a suction pipe 24 is installed in the middle of the upper side of the cover plate 21, an inner pipe 32 slides vertically in the suction pipe 24, and the lower end of the inner pipe 32 is provided with a disc-shaped The mixing extractor 31, the side part of the mixing extractor 31 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com