Piggyback type drying and conveying device capable of achieving climbing and rotation of skid vehicle body

A conveying device and piggyback technology, which is applied in the field of piggyback drying conveying devices, can solve the problems of increased drying time, lengthened drying furnace length, limitation of conveying mode, etc., and achieves the effect of flexible design and small frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

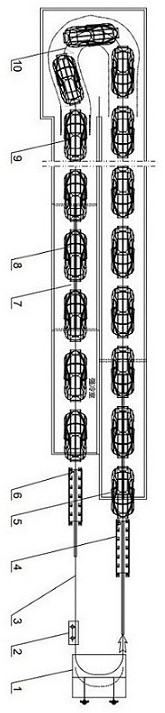

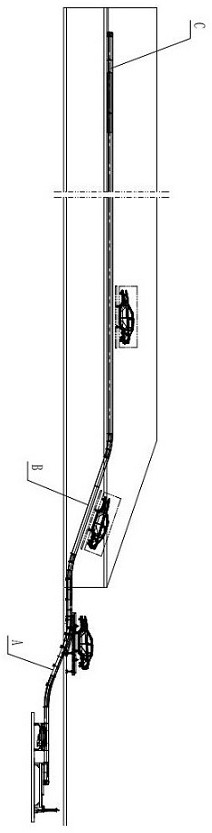

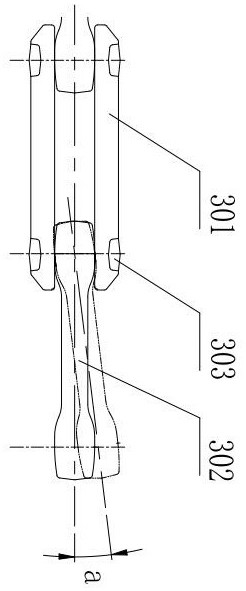

[0038] like figure 1 The shown piggyback drying and conveying device that can realize the climbing and turning of the skid body includes a U-shaped drying furnace 8, a rotary conveying track and a chain assembly 3, a driving device 2, and a piggyback vehicle group. , The skid 9 carrying the vehicle body, the conversion station and the weight tensioning device 1. Wherein, the drying furnace 8 includes an upward slope section 5 of the drying furnace, a horizontal turning section 10 of the drying furnace and a downward slope section 7 of the drying furnace connected in sequence, and the conversion station includes an inlet conversion station 4 and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com