Maintenance method for online replacement of crane end beam

A crane and datum line technology, which is applied to the crane of the trolley, the load hanging element, the crane, etc., can solve the problems of long maintenance time, secondary error of maintenance data, and high demand conditions, so as to ensure the quality of maintenance and reduce secondary damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

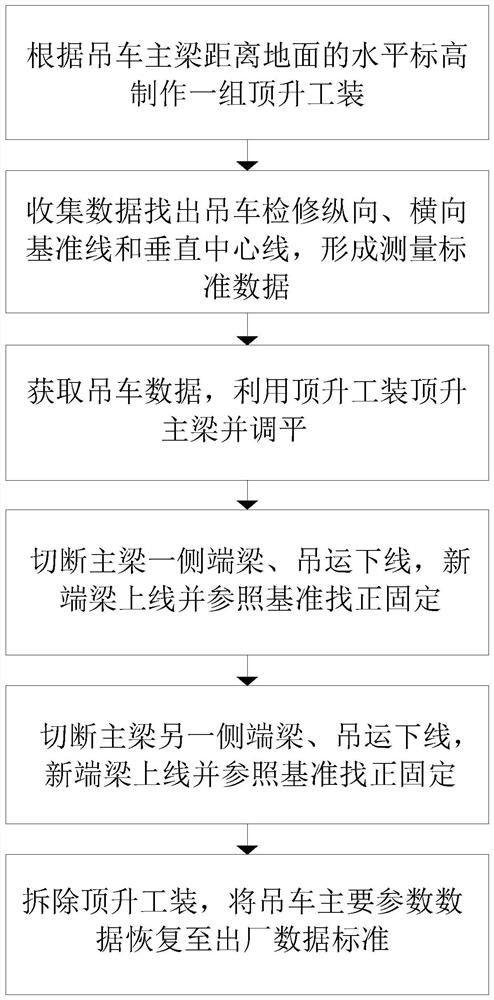

[0026] according to figure 1 , 2 As shown, the present embodiment proposes a maintenance method for online replacement of a crane end beam, including the following steps:

[0027] Make a set of jacking tooling according to the horizontal elevation of the crane main beam from the ground;

[0028] Collect data to find out the vertical, horizontal reference line and vertical center line of crane maintenance, and fix the three reference lines with steel wire to form measurement standard data;

[0029] Obtain the diagonal data of the crane, the parallelism data of the main beams on both sides of the end beams on both sides, and the fixed angle data of the end beams, move the crane trolley to the opposite side of the replacement end beam, and use the jacking tool to lift the main beam and level it;

[0030] Cut off the end beam on one side of the main girder, hoist it off the assembly line, put the new end beam online and find it within the standard range with reference to the dat...

Embodiment 2

[0034] according to figure 1 , 2 As shown, the present embodiment proposes a maintenance method for online replacement of a crane end beam, including the following steps:

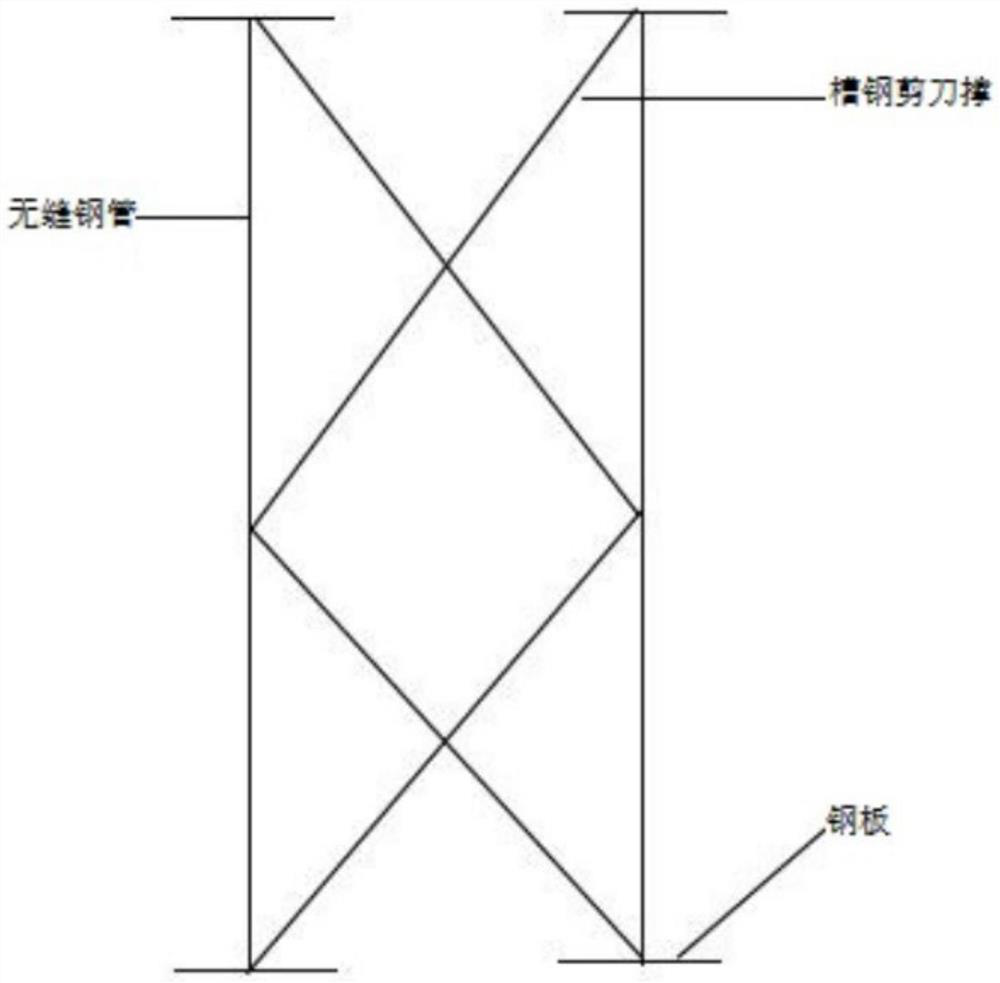

[0035] The jacking tooling selects seamless steel pipe, installs channel steel scissor braces on the inside of the seamless steel pipe to form the tooling, and then uses steel plates to seal the upper and lower surfaces of the tooling. Specifically: DN350 seamless steel pipe, selected according to the height of the crane, with a screw jack below to adjust the height; 5# channel steel scissor support; 500mm*500mm*10mm steel plate.

[0036] Find out the vertical reference line for crane maintenance, specifically: park the crane at a position with high track flatness, take the track elevation as the reference point, implement the method of multi-point measurement and take the average value, and measure the track elevation as the maintenance measurement data The longitudinal reference line is used for the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com