Vacuum flexible grabbing mechanical hand

A gripping manipulator and flexible technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of reduced production efficiency, increased defect rate, and impact on production efficiency, so as to ensure yield and production efficiency, avoid industrial accidents, The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

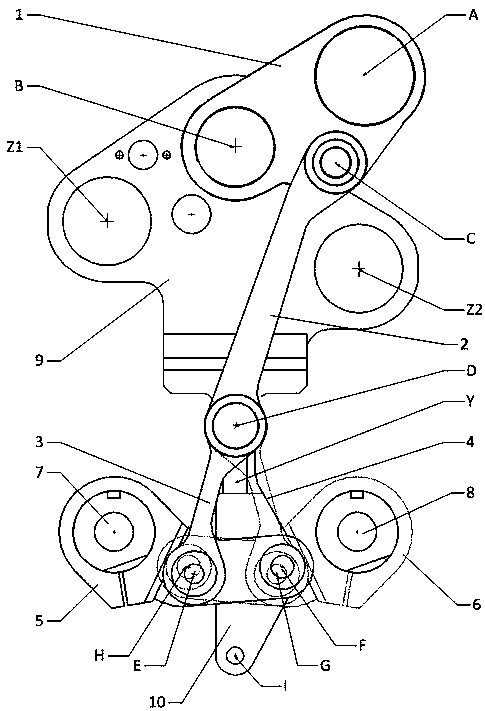

[0026] The invention provides a vacuum flexible grasping manipulator, which is installed on the aluminum can production line, and its structure is as follows: figure 1 shown, including:

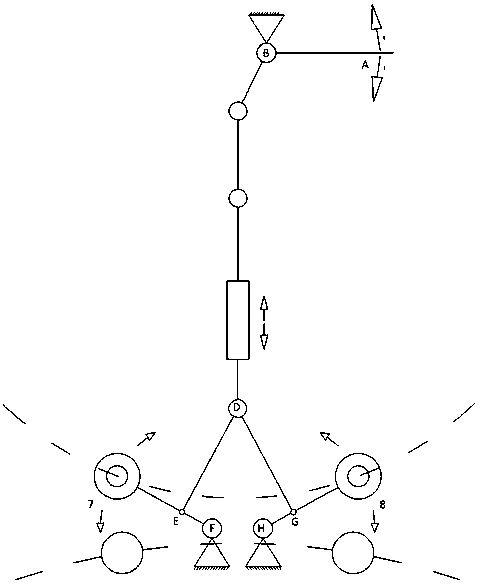

[0027] The driving swing arm 1 is installed on the driving support plate 9 through a pull rod B, and the driving swing arm 1 is sleeved on a swing rod (not marked) through the hole A. Driven by the reciprocating swing of the swing rod, the driving swing arm 1 is The axis of B is the center, and the line connecting the center of the hole A and the center of the railing B is the radius, making a fan-shaped reciprocating motion; combined figure 2 As shown in the schematic diagram of mechanical movement, the center of hole A will move vertically.

[0028] Further, a support plate 10 is fixedly connected to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com