Wastewater treatment oxidation tank

A waste water treatment and oxidation tank technology, applied in the direction of oxidized water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of large bubbles floating up and escaping, uneven distribution of oxidized air, etc., to achieve Effect of reducing COD value and ensuring up-to-standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

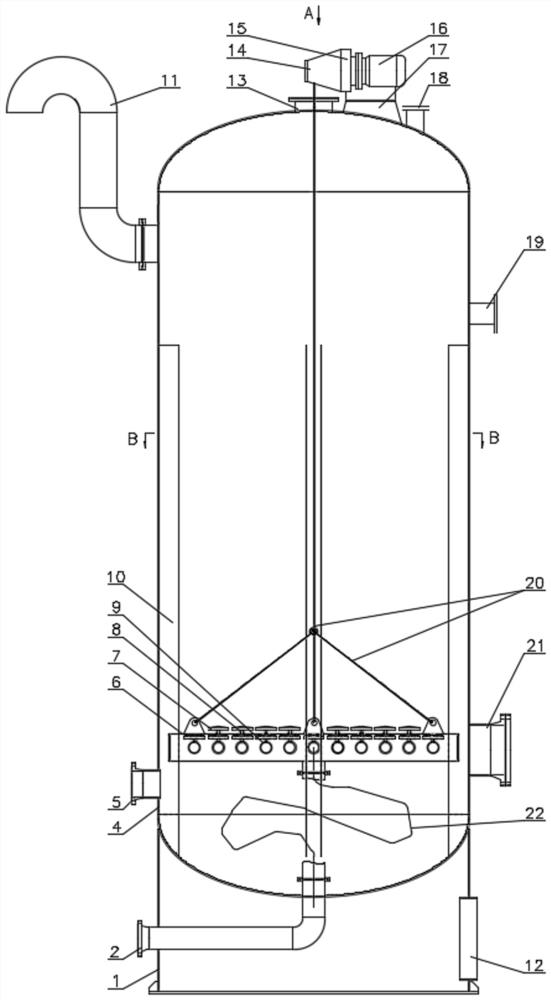

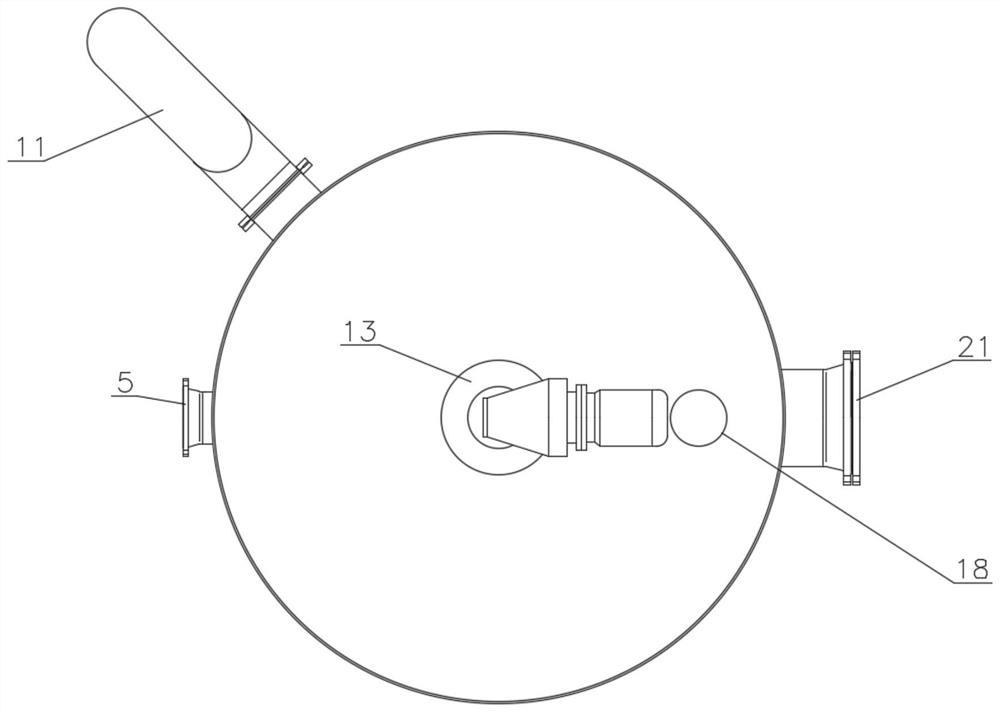

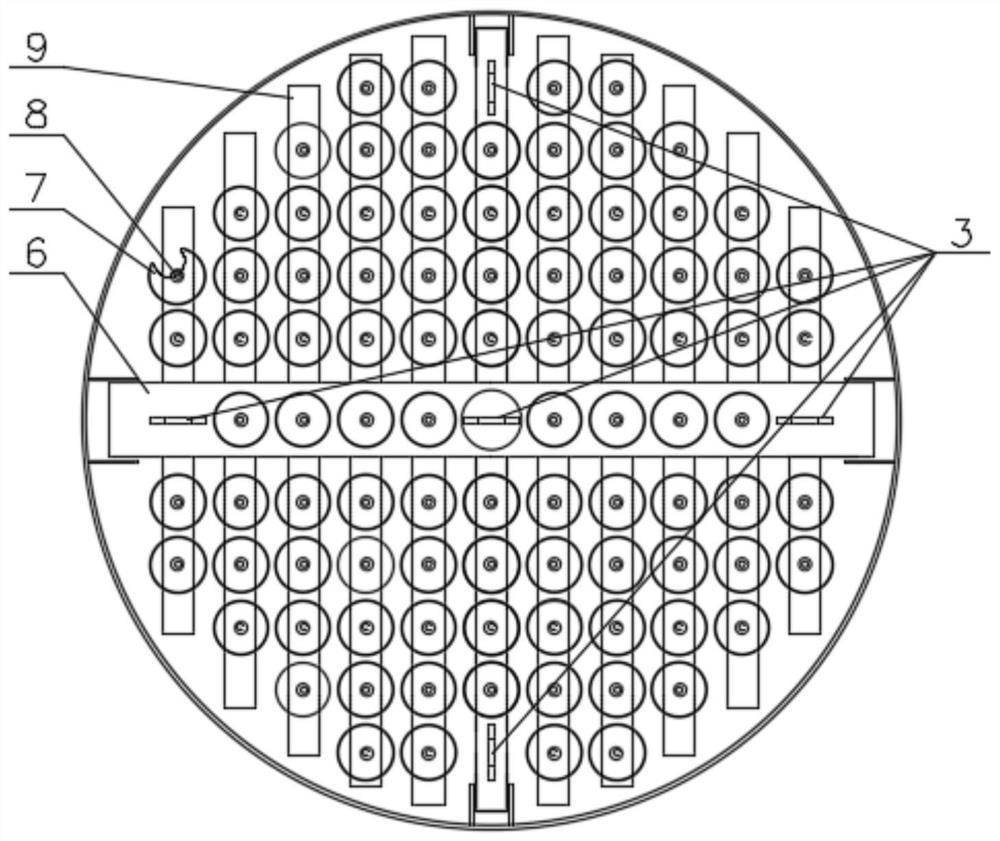

[0031] like figure 1 As well as figure 2 As well as image 3 A kind of wastewater displays the oxidation tank. The lower part of the cylinder 4 is set to be oxidized air entrance 2 and the import 5 of the wastewater. There are overflow drooling 19 and human holes 21; skirt 1 is supported at the bottom of the tank, and a skirt is opened on the skirt to check the hole 12; the two ends of the flexible hose 22 are connected to the oxidized air entrance 2 and the aeration device 6 connected devices 6, respectively. Pass; branch 9 vertical connection on both sides of the supervisor 6, the top 6 of the supervisor 6 and the support of the branch pipe 9 are distributed and connected to the tube mouth 8, the aeler 7 connects to the tube mouth 8; The plate -based firing film, the number of discullars of the plate, the single membrane pores of the plate, the thickness of the thin film, the thickness of 2mm, the diameter of the bubbles is 0.16mm, the effective aeration area is 0.023 square mete...

Embodiment 2

[0033] like figure 1 As well as figure 2 As well as Figure 4 A kind of wastewater displays the oxidation tank. The lower part of the cylinder 4 is set to be oxidized air entrance 2 and the import 5 of the wastewater. There are overflow drooling 19 and human holes 21; skirt 1 is supported at the bottom of the tank, and a skirt is opened on the skirt to check the hole 12; the two ends of the flexible hose 22 are connected to the oxidized air entrance 2 and the aeration device 6 connected devices 6, respectively. Pass; branch 9 vertical connection on both sides of the supervisor 6, the top 6 and the top pipeline 9 are distributed and connected to the tube mouth 8, the aeler 7 connects to the tube mouth 8; The material of the plate -type aeration film, the number of plates of the plate -type aeration film, the number of only film pores, the thickness of 2mm, the diameter of the bubbles is 0.1mm, the effective aeration area is 0.1 square meters, the standard ventilation is 9m 3 / h; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com